Results 1 to 10 of 21

Hybrid View

-

10-17-2013, 03:16 PM #1

Thanks Glen - Kroil it is. Did some research and it looks like spending a few $ more and waiting a few days for the shipment is worth it. Hell I was thinking about Liquid Wrench which probably would have melted the blade or something equally undesirable (like not work at all or stain it too badly to sand out). The wait will give me time to design some scales anyway.

-

10-17-2013, 03:20 PM #2At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,188

- Blog Entries

- 1

Thanked: 13250

One of the Gunshops should have Kroil in stock

-

10-17-2013, 03:49 PM #3Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

Just out of curiousity, Liquid Wrench actually sounds like a good idea. Has anyone tried it?

-

10-17-2013, 04:03 PM #4

One trick when things are stuck but still should be able to come apart is to put it in the ultrasonic cleaner, it can vibrate anything loose.

Hur Svenska stålet biter kom låt oss pröfva på.

-

The Following 2 Users Say Thank You to Lemur For This Useful Post:

AirColorado (10-17-2013), Chevhead (10-18-2013)

-

10-17-2013, 04:20 PM #5

It's my opinion that if Kroil doesn't free a rusty part, nothing short of a torch will. The stuff is awesome. As mentioned already, gun stores may carry it. I've also seen it at a local wood stove dealer, might check one of those if you have trouble finding it.

-

10-17-2013, 04:34 PM #6At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,188

- Blog Entries

- 1

Thanked: 13250

Yep it works too. Most any real penetrating oil will make a good attempt.

IME

Kroil is just the best, period I have not found any better in years.

PB blaster is much like LW but seems to work a bit faster and a bit better I use it on the Tractor etc:

LW works it is the standard of all these procucts..

-

The Following 2 Users Say Thank You to gssixgun For This Useful Post:

AirColorado (10-17-2013), skipnord (10-17-2013)

-

10-17-2013, 05:44 PM #7

I have used the vinegar soak and then dried and kroiled the blade. Tapping the spine on a hard surface will vibrate the oil into all the hidden spaces. I also padded a small vise grips and used it to wiggle the blade a bit at first and then more and more. If at first it doesn't wiggle penetrating oil, some taps, and a bit of time, some taps, and try again.

I have done about five of them so far and none were without some work.

Do Not Lose the Screw!! It is an odd size that I have not been able to match and today I am taking a frame to a watch/clock maker to see if the horological community has a replacement. Thanks for the reminder!

~Richard

PS. Have appointment with clockmaker for Friday! Watch?? this space.

PPS I do hold the removed blade with a strong magnet to sand the sides of it on a piece of wet dry placed on a softer hard felt equivalent surface to allow the paper to conform to the blade. Don't overdo the top of the blade though.Last edited by Geezer; 10-17-2013 at 09:04 PM. Reason: Oopz

Be yourself; everyone else is already taken.

- Oscar Wilde

-

The Following User Says Thank You to Geezer For This Useful Post:

AirColorado (10-17-2013)

-

10-17-2013, 09:49 PM #8

Some more great info there! Yup I was thinking that the screws were unique - have about 5 or 6 other real framebacks myself that need a clean up so this will come in handy repeatedly.

If you have trouble finding the screws I believe there are a few guys in SoCal on here that may be able to help if they're anywhere near Redondo Beach. If it's still there (been 15 years or so) I used to live in RPV and used a little watchmaker's shop in Redondo a few times for bringing really old wrist watches and pocket watches back to life. Wish I could recall the name of it. It's on the south end of the beach blvd in that little area before heading uphill to PV. IF someone is close-by there let me know and I'll search a bit harder.

-

10-18-2013, 10:51 PM #9

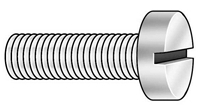

Screw sizes for removable blade framebacks.

Yesterday PS. Have appointment with clockmaker for Friday! Watch?? this space.

Well, the clock maker checked the screw sizes. against his screw cutting dies. (Jewelers' screw plate)

The answer was that most were / are Metric 2.5mm diameter x 0.5 thread. With a socket head they are at your local hobby shop.

And...some are 2.5mm diameter by 0.45mm threading. They are available on line and mostly from sources on the 'bay in packs of 50 or 100 or so for cheap price.

And all were about 5-6mm long.

I used: (Screw, 2.5mm 0.45mm) for a search on the "Bay

~Richard

PS. Cheese head would be the closest to historical usage. ( My guess was many have been replaced over the years )

Have fun!

PPS. I just ordered a pack of the 2.5'x 0.45 pitch. Will send out some if needed. PM me if so. Will have by the end of the month. Nov.1 or soLast edited by Geezer; 10-18-2013 at 11:13 PM. Reason: added info

Be yourself; everyone else is already taken.

- Oscar Wilde

-

The Following 2 Users Say Thank You to Geezer For This Useful Post:

AirColorado (10-19-2013), BobH (10-19-2013)

24Likes

24Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote