Results 11 to 20 of 20

Thread: getting blade to center?

-

10-24-2013, 10:40 PM #11

Be CAREFUL if you try to straighten your blade:http://straightrazorpalace.com/show-...6385-crap.html

Ed

-

10-24-2013, 11:35 PM #12< Banned User >

- Join Date

- Dec 2012

- Location

- Long Island NY

- Posts

- 1,378

Thanked: 177

Ive seen some short at the heel but that blades just ridiculous!

-

10-24-2013, 11:46 PM #13Junior Member

- Join Date

- Dec 2011

- Location

- md

- Posts

- 19

Thanked: 6

I've put a drop or two of Crazy Glue on the inside of the scales near the tang. It takes very little to push the blade in line.

-

The Following User Says Thank You to babbott For This Useful Post:

spazola (10-25-2013)

-

10-25-2013, 02:30 AM #14< Banned User >

- Join Date

- Aug 2013

- Location

- Chalmette LA

- Posts

- 109

Thanked: 10

-

10-25-2013, 02:39 AM #15Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

-

10-25-2013, 02:43 AM #16Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1185

Yeah and if you do it wrong then what ? Your kind of stuck :<0)

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

10-25-2013, 04:15 AM #17< Banned User >

- Join Date

- Aug 2013

- Location

- Chalmette LA

- Posts

- 109

Thanked: 10

-

10-25-2013, 08:37 PM #18

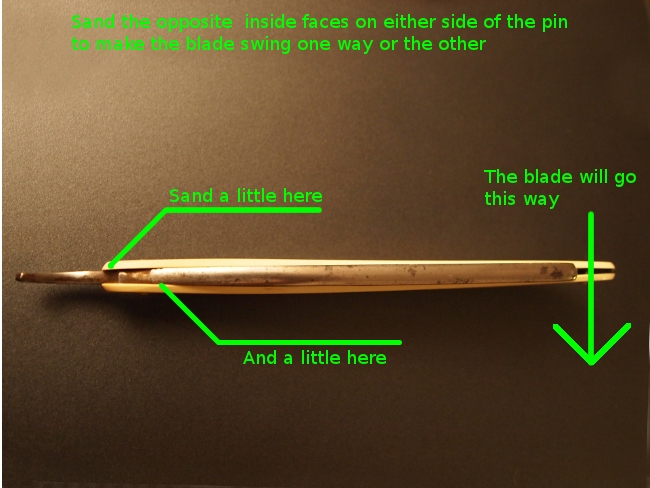

I'm making a set of wood scales for a Wade and Butcher Frameback. It had to be done. The old ones were warped and had a crack I tried to glue which didn't last. So I have the scales nearly complete except for final smoothing and finishing. I'm in the fitting stage using microfasteners. My blade was hitting the side every time. It would not close center. So I searched these here forums and found this thread and other older ones. I did what gssixgun said about checking the straightness of the tang and wouldn't you know the toe of the spine sits higher off the table on one side over the other. So then I found this image below showing where to sand to make the adjustment on the scales. So I worked at at and I what I noticed as I progressed was a visible gap forming between the side of the tang and the scales. I never thought to check this before I had the problem of an off center blade. I think the tang touching the scales would be a bad thing particularly with wood scales and the moisture issues. So back to the adjustment. As I sanded the scale where the tang was touching followed with test fits, I observed the gap open up until I could see only one area touching the tang. Once I created a complete gap, PERFECT CENTER! And by gap I mean i have to hold it up to the light and allow light to shine through. I do not mean a gap so wide it looks ugly! Now I also overcompensated the sanding after I managed a centered blade just to compensate for wood expansion and contraction with humidity. SO now I get to do some finish work.

Image of how to adjust by sanding scales below (found right here on these forums I don't know the original poster to give credit-but he deserves it!).

Last edited by Fort; 10-25-2013 at 08:43 PM.

"The blade must always be respected"

-

10-25-2013, 09:11 PM #19Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1185

Annnnd That's the way you do it !

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

10-26-2013, 06:11 AM #20

14Likes

14Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote