Results 1 to 10 of 13

Thread: Slowing down a Grizzly

-

03-31-2014, 03:44 AM #1

Slowing down a Grizzly

Slowing down a Grizzly

Hey there,

Has anyone heard of disconnecting the motor from the sanding part (pivot arm etc) of a Grizzly 1015 in order to run a pulley system to slow things down?

I had a quick Google but nothing came up. I just bought one of these locally and when I downloaded the manual, I realized the sander part is separate from the motor and could bolt down securely on its own. With a couple of pillow blocks and pulleys, I wonder if the stock motor could be adapted to a 3-speed.

Any thoughts?

-

03-31-2014, 04:13 AM #2

You can do anything if you make it work. A neighbor of mine has constructed belt-driven grinders powered by washing machine motors. One could make any sort of grinding/sanding apparatus with a power source and the right combination of belts and pulleys-which can be stacked like a drill press for multi-speeds. Or like a bicycle multi-gear drive, which would require a tensioner to use a single belt length.

Think outside the catalog.Buttery Goodness is the Grail

-

The Following User Says Thank You to WadePatton For This Useful Post:

spazola (08-31-2014)

-

03-31-2014, 05:41 AM #3Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184

I would say yes. I just reconfigured a Craftsman 2 x 42 to a 2 X 72 and new motor with 4 step pulleys. You can almost watch a point on the belt go around. The hardest part is getting it all lined up but hard is a relative term now isn't it :<0)

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

03-31-2014, 03:46 PM #4Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

-

03-31-2014, 03:52 PM #5

Yes, please. No hijack... Pics always help.

-

03-31-2014, 04:46 PM #6

On seeing the title my first thought was a 12 ga with slugs.

Why not an electronic speed controller and skip the pulleys, blocks and belts?The easy road is rarely rewarding.

-

03-31-2014, 06:12 PM #7

I nearly sac-rificed my left (something valuable) just to buy the Grizzly... A VFD may be something for the long-term view but not in the cards just now.

-

04-01-2014, 03:47 PM #8Senior Member

- Join Date

- Nov 2013

- Location

- Houston, TX

- Posts

- 147

Thanked: 45

You can absolutely three-step this thing! The hardest part of the whole process is going to be getting all the right parts to do the build. You have to know what size everything is, and if the drive shaft is keyed, etc. Once you've got all the parts, you just lay everything out on a piece of plate or wood and then start your build. I know that Charlie likes to use hinges and clamps to make it easier to change pulleys. So that's definitely an option. On my KMG, I just cheat the belt over and rotate the pulley and it'll slide off. I rather like that, but I've never tried Charlie's way, so I'm not sure what's easier.

I'm interested to see pics of the unassembled Grizzly so I can assess exactly how difficult this will be. Will you be using this beast for razor making? 3600 ft./min. is a pretty quick belt speed, but that is the one I tend to use most often. It makes rough grinding go quickly, but the faster the belt, the bigger the mistakes Let me know if you need any help with shaving, honing, etc.

Let me know if you need any help with shaving, honing, etc.

-

04-05-2014, 09:26 PM #9

Well, I probably won't take on this project just yet but I can confirm that the Grizzly with a 36 grit ceramic belt moves through steel in a _fast_ kind of way.

I ground a 1.25" by .25" blade in about an hour. Much less time for mistakes than the bench grinder, and I can see slowing it down one day. I'll need more room to lean the arm back though, and that will have to wait till we move (for kids, dogs etc, not just my hobbies).

-

04-05-2014, 10:25 PM #10Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1184

I have been taking pictures until I got it running LOL. Now I play and add and play and add. I did not do an as build thread because of the time and other projects plus , I didn't think many would take an old 2"x42" Craftsman belt grinder and repurpose it. I will get some nice pics when it's done. Right now I am making a platen for it.

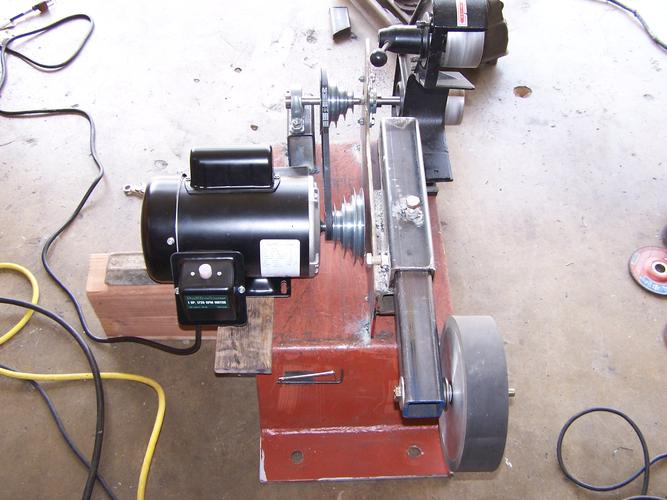

This is the layout and tack it stage of the build. I have added handles and cut the monster it's sitting on down to 2" high to fit my work bench at the right height.

You can see the pulley set up well enough I hope. The shaft and drive wheel are separate from the cast housing of the old Craftsman grinder. I used the cast part to enclose most of the belt for a water cooling system later if I need it.That and the tracking wheel set up was already there. I had a lot to align and if I started again I wouldn't have gone this way. I may feel different if I add the water :<0)

It still doesn't have a switch yet.Good judgment comes from experience, and experience....well that comes from poor judgment.

-

The Following User Says Thank You to 10Pups For This Useful Post:

spazola (08-31-2014)

11Likes

11Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote