Results 1 to 10 of 13

-

06-16-2014, 10:34 PM #1Senior Member

- Join Date

- Apr 2014

- Location

- Berks Cty, Pa

- Posts

- 234

Thanked: 25 Re-scaling project coming together

Re-scaling project coming together

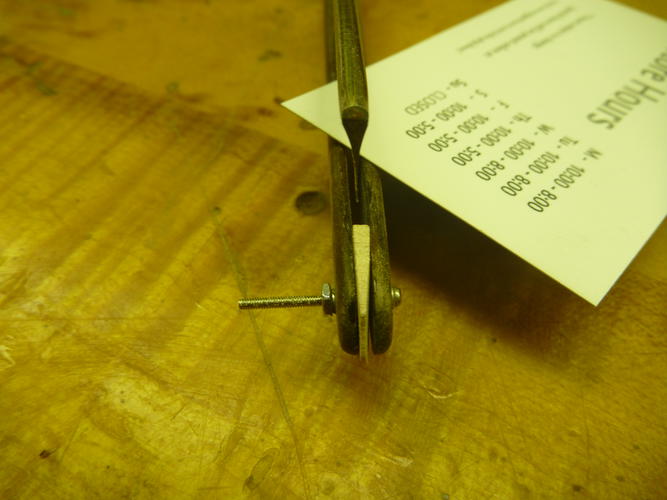

The screws/nuts ordered came in today. This allowed the first fitting of the Ebony scales I'm working on (first attempt)

The blade closed centered in the scales. That was a surprise.

Another surprise was my carefully shaped Maple wedge may be not sized correctly.

It has the same measurements as the original, but I guess plastic scales bend more.

Time to shape another one.

-

06-16-2014, 10:42 PM #2Senior Member

- Join Date

- May 2013

- Location

- Des Moines, IA

- Posts

- 295

Thanked: 60

Scales are looking good so far. Hard to tell, but it doesn't look like the screw is very tight on the wedge, which could potentially be responsible for some of the gap at the wedge. Again, hard to tell just from photos. Best of luck with the rescale, and post more photos of the completed razor!

-Chris

-Chris

-

06-16-2014, 11:02 PM #3

Scales look really nice for a first attempt. I would tighten the wedge end first then the pivot. The thicker the scales the harder it is for them to flex. Especially with really dense woods.

-

The Following User Says Thank You to JSmith1983 For This Useful Post:

Kentuckygent (06-17-2014)

-

06-16-2014, 11:02 PM #4Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Your wedge is not right,to thick on the blade side.maybe to long also.

Your centering at this point really means nothing with the screws,proper centering is done with the peening.CAUTION

Dangerous within 1 Mile

-

The Following User Says Thank You to pixelfixed For This Useful Post:

carrolljc (06-22-2014)

-

06-16-2014, 11:15 PM #5Senior Member

- Join Date

- Apr 2014

- Location

- Berks Cty, Pa

- Posts

- 234

Thanked: 25

Are you saying that centering is adjustable during the peening process?

The screws are just snugged a bit, no real tightening. The gap looks much to large to draw down and would produce a large opening in the middle of the scales. A new wedge is coming.

The inside surfaces have 5 coats of CA. Once the wedge deal is sorted out, the outside finishing will get under way.

-

06-16-2014, 11:20 PM #6Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

-

06-16-2014, 11:21 PM #7

The shape and wood look great, however, that wood won't bow to accommodate a wedge-shaped wedge. Unless you really thin out the scales, save yourself some trouble and make a spacer. A wedge with no wedge, so to speak!

"Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

The Following User Says Thank You to sharptonn For This Useful Post:

Neckbone (06-17-2014)

-

06-17-2014, 11:16 AM #8Senior Member

- Join Date

- Apr 2014

- Location

- Berks Cty, Pa

- Posts

- 234

Thanked: 25

-

06-17-2014, 11:29 AM #9Senior Member

- Join Date

- Apr 2014

- Location

- Yorkshire , England

- Posts

- 356

Thanked: 44

Looking good so far. It's hard to tell from your pictures but do the scales have a rounded edge or do they have a square edge ?

-

06-17-2014, 11:48 AM #10I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

Shape is great, you can thin out the scales a bunch so that they flex easy, then your wedge will fit.

Ebony is pretty string wood and will work fine at small thickness.Stefan

-

5Likes

5Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote