Results 61 to 70 of 90

-

07-28-2014, 05:17 PM #61

-

07-28-2014, 07:00 PM #62

I have played around with making hones with various binders, shellac, acrylics, hide glue, epoxy. I also used various abrasives. I was never happy with what I made. I never could get the binder to abrasive ratios where they needed to be. I always ended up with too much binder and not enough abrasive. The first hones I made would better an 8k edge, but had the worst feed back of any hone. It was like honing on plastic. Randy and I messed around a lot and bounced ideas back and forth. I gave up on hone making, Randy has moved on to better ideas.

Most of my ideas and previous home made hones can be found using the search function on this forum.

Charlie

-

-

07-28-2014, 07:09 PM #63

I was thinking about this last night. One option that might work with CrOx is sputtering it onto glass. I've done it before, but it was only for a 1 mil layer to help bond two pieces of glass together on their faces. I suppose you could build up layers of the stuff though. Essentially turning it back into rock with a glass substrate.

Some people never go crazy. What truly horrible lives they must lead - Charles Bukowski

-

07-28-2014, 10:57 PM #64

Cost an arm and a leg (Resound) but the Hearing Aid remote for the TV sound has stopped a lot of nasty looks and scrambling for the remote. Aside from that I hate them also because you know you are not hearing the real sound that you once heard......kind of like the pills that turn back the clock on your Johnson....not quite the same as being 25 again.

"Call me Ishmael"

CUTS LANE WOOL HAIR LIKE A Saus-AGE!

-

07-28-2014, 11:31 PM #6550 year str. shaver

- Join Date

- Aug 2008

- Location

- Pothole County, PA

- Posts

- 2,258

- Blog Entries

- 2

Thanked: 522

-

The Following User Says Thank You to mrsell63 For This Useful Post:

guitstik (07-29-2014)

-

07-29-2014, 01:50 AM #66Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

Hi guys

I have been in Wisconsin working on my Mothers home where the basement has become a haven for mildew and mold.

White mold, yellow/gold colored mold and a small patch of black mold ( so far). All items in the basement have to be moved or discarded. Today I disposed of 5 loads in my pickup truck. About another 5 to go. Then I start the process of removing the sheet rock and styrofoam from the walls. etc etc etc. I may be done in September, no joke.

Geezer told me about this thread so tonite I am at his home using his computer. To the OP, this sounds like a very good project! Give it a try! You will find it interesting and challenging. I have not used those materials as a binder before so I cannot give you any guidance. Yes, I do know how the the hones were made and I fully intend to produce them once life stops sidetracking me from my hone making project. The equipment is darn near done.

You will find it interesting and challenging. I have not used those materials as a binder before so I cannot give you any guidance. Yes, I do know how the the hones were made and I fully intend to produce them once life stops sidetracking me from my hone making project. The equipment is darn near done.

BTW... I have 10 lbs of chrome ox! ...........................

...........................

and 1800 lbs of other abrasives plus mucho binder etc.

I will try to check in 1-2 times per week so please forgive me if I do not respond immediately.

Have a good time with this Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

-

07-29-2014, 01:53 AM #67

Thanks Randy. I won't hit you up via email or IM's, if you have any advice along the way feel free to IM me.

SRP. Where the Wits aren't always as sharp as the Razors

http://straightrazorplace.com/shaving-straight-razor/111719-i-hate-you-all.html

-

07-29-2014, 09:43 AM #68Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

-

07-29-2014, 10:03 AM #69Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

There have been various threads, on this site and on others, with regards to making hones. One of the most promising - and long-lived threads was on another forum. The main stumbling block was mixing the ingredients - after a certain concentration, the solids no longer want to go into suspension, they prefer to cluster together in small 'globs', so some sort of special mixer was required.

I do not recall the end of the experiment - it went on for so long and was of pretty limited appeal to me anyhow, kind of like finding a more involved and more expensive way of re-inventing the wheel. However, I have some training in cementitious products, and the finest mixer was not a tumbling or bladed device, but a pan-mixer with paddles used for making very fine fondue cement.

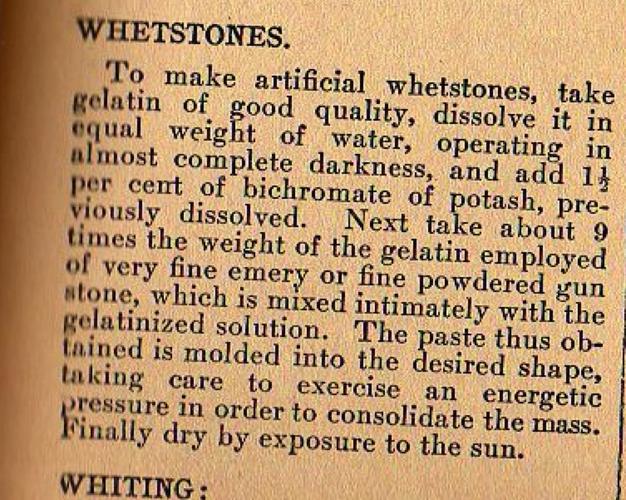

From one of the old threads I found the glue/potassium dichromate mixture I told you about before (gelatin is used here, but any derivative can be used including the old, proprietary glues like 'Gloy'):-

Note that this is still 'squeezed' to remove excess moisture. An arbor press with a suitable shoe to fit the mould can be used, as can its stronger brother the 'H' arbor press that screws dwn rather than using a hand lever like a conventional arbor press. An old fly press is also suitable, and more easily available (and considerably cheaper) options can be cobbled together from square section steel and hydraulic bottle jacks, like a car shop press.

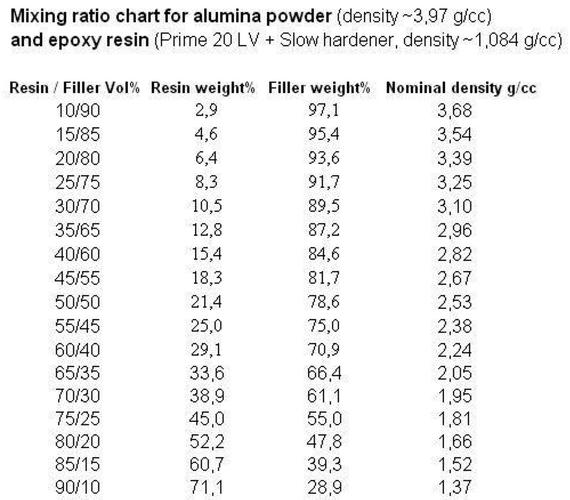

From the same thread, here is a list of additives and ratios:

There was not really anything else of interest in that thread - it linked to a foodie forum that is no longer extant for further info.

I would imagine that a search of the American Patents Office - which is online - would help. As I said, all of this stuff has been done before, on a large scale. No reason why it should not be repeatable. Hell, Spyderco even produced one of their hones as a 'new' barbers hone, not that it got much use in the razor world. It was very hard, reminiscent of ceramic, and proved (to me, anyway) the ideal medium for abrasive pastes and powders like diamond.

Regards,

Neil

-

The Following User Says Thank You to Neil Miller For This Useful Post:

guitstik (07-29-2014)

-

07-29-2014, 12:09 PM #70

It's just like about the same formulation for making photography paper/glass plates. The bichromate of potash is light sensitive and mixed with the gelatin, usually made from bovine hoof, hardens when exposed to sunlight. I have used that over the years when doing photographic art works. A search of the US patent office web site did nothing but to confuse the heck out of me by making me chase down differing subclasses. I don't know how you do it Neil, you must have the patients of Job.

SRP. Where the Wits aren't always as sharp as the Razors

http://straightrazorplace.com/shaving-straight-razor/111719-i-hate-you-all.html

180Likes

180Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote