Results 1 to 10 of 15

-

08-04-2014, 02:57 AM #1

When do you stop chasing stubborn pitting?

When do you stop chasing stubborn pitting?

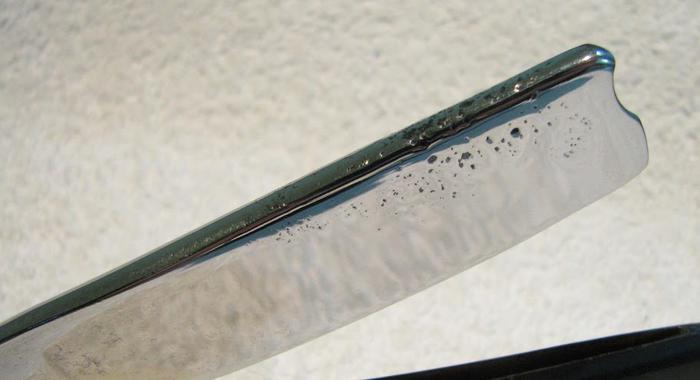

I found my first George Wostenholm Pipe Razor at an antique store in Cadiz, KY and couldn't pass it up. I loved the design on the blade so I was hoping to bring it back to life, but the bottom edges of the design were lost to years of honing (I assume), and the whole blade was covered in pitting of varying depths. I worked on it all day today (the exact process as well as before and after shots are below) and even though it looks much better than it did - I still have an urge to 'chase' the lighter pits that cover the razor. I would really like to restore this blade to its former glory, but my questions to you gentlemen are - at what point do you stop chasing the pits in order to ensure the integrity of the shaving edge isn't compromised? And what else can I try to get rid of the lighter pitting that remains? At the end of the day I don't want a display piece - I definitely want a shaver.

Here's what I have done to it so far (about 12 hours start to finish):

1 - 2 very low speed, careful passes with 180, 280, and 320 grit polishing wheels on the dremel

2 - Wet/Dry sandpaper (180 grit to 2000 grit - started adding WD40 at 400 grit)

3 - Micromesh (3200 - 12000)

4 - Maas (Let it ALMOST dry, then rubbed off with a hand towel)

5 - Honed (Naniwa progression)

-

08-04-2014, 03:55 AM #2Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

It is a long tough road starting with a blade that far gone and bringing it that far. If you use 0000 steel wool with your polish it will clean the black out of the pits. It won't remove the pits, just the black. The black incidentally is corrosion, and if you want it to show it's age there are ways to darken the blade. That amount of deep pits will require a lot of steel to be removed.

It's not what you know, it's who you take fishing!

-

-

08-04-2014, 04:11 AM #3

From the hone wear (toe heavy) and the condition of the pivot hole this Wosty has been "rode hard are put up wet" as we say..

That fact that you have it looking this good is very impressive - I would have passed.

RezDog's suggestions for getting the black out of the pits is good - and as he advises the pits are still going to be there.

Removing the pits will remove the etching - and you would have to think about how that would effect your view of your handiwork.

And remember there are other razors out there waiting for you to restore...

Smooth ShavingSupport Movember!

Movember https://mobro.co/markcastellana?mc=1

SRP Team USA https://moteam.co/srp-usa?mc=1

-

08-04-2014, 04:15 AM #4

Until you're happy with the result. I think that leaving some pitting in antique Sheffield razors is fine.

This is one I restored a little while ago. I got it to a mirror finish so that was fine for me. I wasn't interested in trying to get rid of any more of the pitting.

-

08-04-2014, 04:24 AM #5

any further & you would be looking at a regrind not a restore I think

Saved,

to shave another day.

-

08-04-2014, 11:30 AM #6

Thank you all for the quick responses. MJC, you're right about the starting condition of the blade - I've never worked on one that started off this bad before.

I'm going to grab steel wool this morning and try to get out the darker spots like you suggested RezDog. Once I get after the blade with the 0000 steel wool, am I going to have to run it back through the W/D sandpaper progression to remove scratches made by the steel wool?Last edited by bearborne; 08-04-2014 at 11:34 AM.

-

08-04-2014, 12:02 PM #7

Instead of steel wool to get to the dark areas there are several chemical options for getting down into the pits. I personally use a 20:1 mix of water and sorghum molasses that works well at removing corrosion and won't make you have to re-sand afterwards. There are also several other products on the market that would do the same thing. Good work by the way.

SRP. Where the Wits aren't always as sharp as the Razors

http://straightrazorplace.com/shaving-straight-razor/111719-i-hate-you-all.html

-

The Following User Says Thank You to guitstik For This Useful Post:

bearborne (08-04-2014)

-

08-04-2014, 12:19 PM #8

Guitstik, what proportions are you using? Like 1 tbs sorghum to 20 tbs water? And how long do you let the razor soak?

-

08-04-2014, 12:27 PM #9

For an object that small tbs would be about right and to answer your question, that is the ratio that I use 20 parts water to 1 part sourghum. You can play with that ratio some but I wouldn't go less than 10:1 and don't use it on soft metals or scales. That ratio, by the way, is for pure sourghum molasses.

Last edited by guitstik; 08-04-2014 at 12:30 PM.

SRP. Where the Wits aren't always as sharp as the Razors

http://straightrazorplace.com/shaving-straight-razor/111719-i-hate-you-all.html

-

08-04-2014, 01:08 PM #10

Youve done fine job of cleaning her up. In my opinion your done, and any further you will lose what makes this razor appealing.

8Likes

8Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote