Results 21 to 24 of 24

Thread: Help with an 8/8 Butcher restore

Threaded View

-

09-23-2014, 02:02 AM #1Senior Member

- Join Date

- Dec 2013

- Location

- Virginia

- Posts

- 1,516

Thanked: 237 Help with an 8/8 Butcher restore

Help with an 8/8 Butcher restore

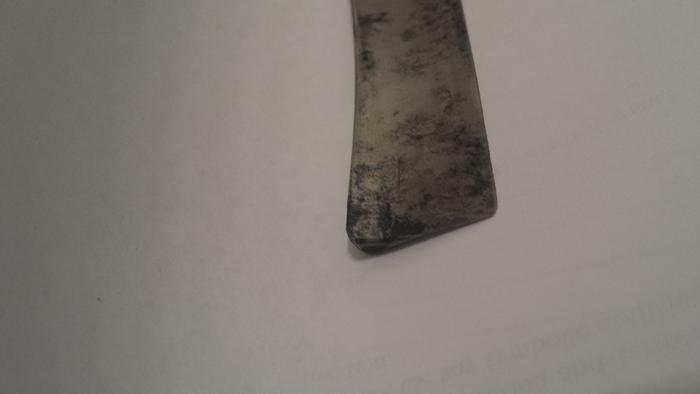

hello all, i recently picked this guy up for a decent price and have started to clean it up. It has some issues with rust/pitting, but it is not the worst ive ever seen. So my question is how much of it do i remove before i call it quits? I have only very lightly sanded the really bad spots and lightly hand polished the whole blade to get an idea of where its at and how to proceed. Im leaning towards just lightly sanding the whole thing, then putting it in the tumbler for a few days in walnut then a few more in red corn cob. Any suggestions would be appreciated. Thanks

16Likes

16Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote