Results 1 to 8 of 8

24Likes

24Likes

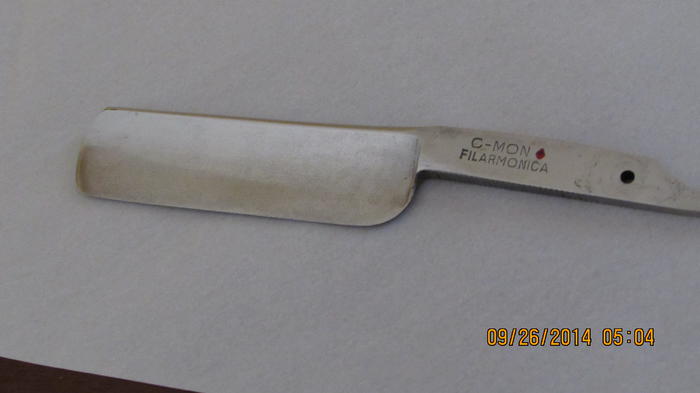

Thread: Need Help with a C-MON/FILA restore

Threaded View

-

09-26-2014, 08:44 PM #1

Need Help with a C-MON/FILA restore

Need Help with a C-MON/FILA restore

Here is what I got. I am thinking I need to sand more get down to clean metal. I am too scared to try greaseless on a full hollow. Any input would be helpful. I just see pits and residual rust left overs .My thoughts are I didnt go down deep enough to remove all the gunk.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote