Results 1 to 10 of 31

Thread: Pinning Anvil

-

12-12-2014, 08:12 PM #1Member

- Join Date

- Aug 2014

- Location

- New Hampshire

- Posts

- 43

Thanked: 11 Pinning Anvil

Pinning Anvil

So, there I was sitting in my shop with a nice single malt pondering the whiches of why and thinking I need a new anvil. This got me to thinking about pinning razors and how it is just plain awkward working on the back of the vice, so I decided that I would try something different.

I found myself a railroad spike, made hole in a 4x4 just large enough to keep the spike from splitting the wood to mount it, I then polished the big end and drilled a hole about 1/16" deep on the back edge for the pin to set in while peening the other side and the front edge made a great little work space for tapping the pins into place.

Just a thought for those who would like a jewlers type anvil on the cheap and the bonus is that I can now sit comfy while pinning. The only thing necessary for the triumph of evil is for good men to do nothing. (Edmund Burke)

The only thing necessary for the triumph of evil is for good men to do nothing. (Edmund Burke)

-

The Following User Says Thank You to Whimpy For This Useful Post:

Geezer (12-12-2014)

-

12-12-2014, 08:26 PM #2

-

12-12-2014, 08:41 PM #3

I made one a while back using an old MC fork tube, a thick hunk of steel, and an old Jeep spring shackle for a base. Even threaded the middle to accept a drill chuck for doming one side of a pin. Sitting in a comfy chair, feet on the base, much better than standing. Had to fill the tube up with sand to quell the annoying ringing, though!

"Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

-

12-12-2014, 08:57 PM #4Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

-

12-12-2014, 09:00 PM #5

-

The Following User Says Thank You to Nightblade For This Useful Post:

Whimpy (12-12-2014)

-

12-12-2014, 09:28 PM #6Member

- Join Date

- Aug 2014

- Location

- New Hampshire

- Posts

- 43

Thanked: 11

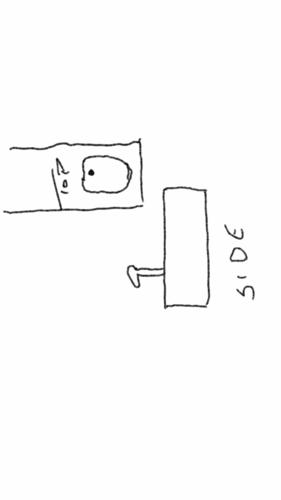

Unfortunately I am out of state for a couple weeks and neglected to take pictures of it.

Unfortunately I am out of state for a couple weeks and neglected to take pictures of it.

But this is a crude drawing of it.Last edited by Whimpy; 12-12-2014 at 09:39 PM.

The only thing necessary for the triumph of evil is for good men to do nothing. (Edmund Burke)

-

The Following 2 Users Say Thank You to Whimpy For This Useful Post:

Geezer (12-12-2014), Nightblade (12-12-2014)

-

12-12-2014, 09:29 PM #7

Generally, I peen one side first, sand the other end flat again by touching it to the belt sander, insert it, cut off the excess, make it flat again, and peen.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

The Following User Says Thank You to Bruno For This Useful Post:

Whimpy (12-12-2014)

-

12-12-2014, 10:29 PM #8

-

The Following User Says Thank You to Geezer For This Useful Post:

Whimpy (12-12-2014)

-

12-17-2014, 10:55 PM #9

Methinks a tow ball could be adapted as an anvil also.

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

The Following User Says Thank You to onimaru55 For This Useful Post:

spazola (12-19-2014)

-

12-17-2014, 11:04 PM #10Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

112Likes

112Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote