Results 1 to 6 of 6

23Likes

23Likes

Thread: Tip for making a workbench

-

12-30-2014, 10:38 PM #1

Tip for making a workbench

Tip for making a workbench

I thought I'd share this nifty trick before I am finished and you can no longer see the wall.

I am in the process of overhauling my workshop, and the last big change is going to be throwing out the improvised wooden table that holds my belt sander, and replace it with a sturdy workbench that will hold at least 2 of those grinders, and possibly 3 sometime in the future. Or 2 grinders and a heat treatment oven, we'll see.

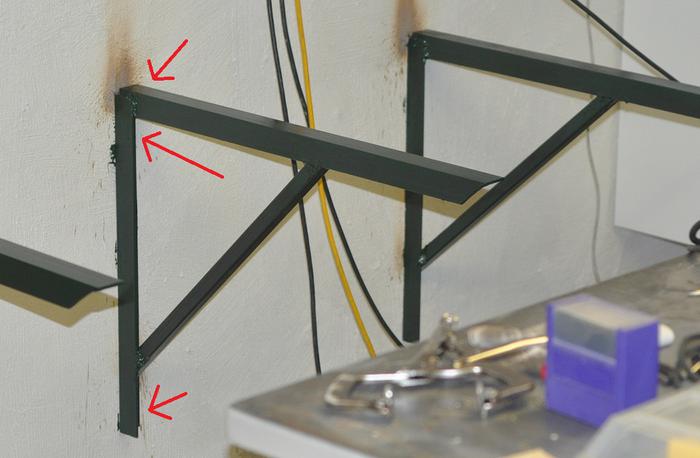

anyway, aside from being sturdy, I wanted the thing to have no legs. The wall itself was not 100% flat, so that made it impossible to just buy wall hooks for supporting my workbench. They would not be level or equal. And most of the off-the-shelf stuff is not for for heavy loads anyway. So I bought a load of steel L beams, roughly 3/16" thick, 1.5" wide. First I mounted the vertical beams. Each of those is mounted to the wall with 3 bolts that are meant for hanging cast iron radiators from a wall (2 bolts will hold a 200 pound radiator easily). the position of the bolt is indicate by the red arrows. I placed 2 bolts at the top because that is where all the weight will pull.

Then I welded on the first horizontal support, using a level indicator to make it perfectly level. I repeated this for the other 2 supports, using the first as a reference. After that I welded on the diagonal square beams. I'll not call it a professional welding job. It is bascially just a frame that I melted together using welding rods. After that I caoted everything in hammerite to protect it from rust. Each of those frames is perfectly level with the others, and is strong enough to hold my full body weight at the full extent of the horizontal support without moving. Now it is ready for the wooden cross beams and the table top.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

The Following User Says Thank You to Bruno For This Useful Post:

Geezer (01-01-2015)

-

12-30-2014, 10:46 PM #2

Btw, in case you are wondering why I call this a nifty trick: I like it because I didn't see any other option for fixing a perfectly level workbench to a wall using off the shelf hooks and supports that would also easily hold a couple of hundred pounds. And this is extremely cheap, and everyone who can do some basic welding can do it.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

12-31-2014, 12:11 AM #3

That's going to be one heck of a work bench! It gives me a few thoughts for when I start my workshop remodel.

-

12-31-2014, 10:33 AM #4

Having no table legs has a couple of benefits. It's much easier to keep the floor clean with a broom or vacuum cleaner. If you want, you can also clean with water and it doesn't affect the table. you also don't have to worry about eliminating wobble caused by an uneven floor.

And in my case, I get some water seeping in through the floor in autumn. this makes is easier to mop up. Next year I plan to make it waterproof and have someone put in floortiles. This way I don't have to move the heavy machines out. For the same reasons I also replaced my shelves with hanging cupboards.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

The Following User Says Thank You to Bruno For This Useful Post:

Geezer (01-02-2015)

-

12-31-2014, 01:57 PM #5

Just mounted the beams and top. Then sat on it with my oldest daughter. didn't even budge a hair.

I'll post pics when my workshop is overhauled completely.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

12-31-2014, 05:31 PM #6

Thanks Bruno! My solution is not quite the same, but it can be very strong is made from commercial shelving supports screwed onto the ( foundation) wall with long concrete screws. There is a large choice of shelf supports here in North America. They can be had up to a couple feet/ 0.6M long with proper angle bracketing built in.

The bench does support my weight. I like being able to change the height of the counter if I wish to. The narrow shelving in the background is nice for wet grinders and others. The wide bench is going to get shelving above it soon with a fluorescent light on the bottom. Again, the space below is usable for Vacuums and other items. The shop is still in a mess from last summer and fall's wettings. The whole shop is 4x4M or twelve by 12 feet. It also has over 3Msq. or 27 square feet taken up by heating and water treatment equipment.

However you can do it, wall benches rock!

Happy New Year!

~RichardLast edited by Geezer; 01-01-2015 at 05:23 PM.

Be yourself; everyone else is already taken.

- Oscar Wilde

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote