Results 1 to 10 of 27

-

01-18-2015, 04:26 AM #1Senior Member

- Join Date

- Feb 2014

- Location

- Florida panhandle, near Ft. Walton Bch.

- Posts

- 247

Thanked: 23 Help with smoothing pin heads and centering the blade please

Help with smoothing pin heads and centering the blade please

I cleaned this razor I got off eBay and made a handle from red MOP pattern kirinite. As you can see the blade is not centered when I close it. The edge doesn't come close to or hit the scale at all. Any suggestions on how to center it? This is the first razor handle I've made that I didn't use glue at all. The few other razor handles I've done I finished the pivot then used glue on the other end. This allowed me to make the blade centered easily. Then I could add a pin for appearance if I wanted. I don't see any need to do that unless I would use something decorative. Also How would I smooth the pin heads? I can feel where the pins are flattened. Were they too long when I peened them maybe? The flattened pin is almost as big as the washer. I'm pretty happy with them but I know they should be smoother. The scales are polished. I don't want to mess that up.

The handle is kirinite. It is very soft material and easily flexed. I think heating it in hot water, shaping it and letting it cool might work. Even if that would work is there a way to be more accurate with centering when assembling the razor? Any help is appreciated.

Jack

-

01-18-2015, 04:36 AM #2

Does not look too awful bad! It looks like the edge will not hit and the blade will guide it in? I often put the blade in a bind with a half-clothespin and pour 180 degree water over the scales and let it sit for a day or 2 in a bind. Seems to get that little bit I need.

I don't know about Kirnite, though. Should hurt nothing to try?

Light sanding and/or polishing the pins will smooth them out. As you gain experience pinning, you will learn to polish the pin with your hammer considerably by using tiny taps all over.Last edited by sharptonn; 01-18-2015 at 04:38 AM.

"Don't be stubborn. You are missing out."

I rest my case.

-

01-18-2015, 04:38 AM #3

I use these tools to smooth & polish my pins,

-

-

01-18-2015, 06:46 AM #4Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

I don't understand how or why it works but if you tap the hinge pin on on side it will move the blade, I can't find a the thread in the workshop but I think you tap the pin on the side you want the blade to move to. There is quite a bit on pinning in here

http://straightrazorpalace.com/works...wers-here.htmlIt's not what you know, it's who you take fishing!

-

01-18-2015, 10:43 AM #5

As Rezdog said for centering

and for polishing pins I just use a denim type cloth loaded with Autosol from when I polish steel.

I just fold it a couple of times then put it on a hard flat surface then polish my pins on it in circular motion and this usually polishes the rough edges of the peeningLast edited by Substance; 01-18-2015 at 11:24 PM.

Saved,

to shave another day.

-

01-18-2015, 01:46 PM #6

I doubt that heating the kirinite will make things better. Kirinit can deform when hot, but that doesn't necessarily mean that you'll magically deform it just the right amount for it to center perfectly

I generally have 2 solutions for this problem.

If you're still in the assembling stage, you can easily sand away a bit of material on the inside of the scales, around the pivot. You have to sand just a bit so that the washer takes on a slightly different angle , and that will move the point from left to right or right to left.

When everything is pinned, you can still fix a bit by tapping. If the blade needs to move, I tap the pin on the side that the point needs to move away from. And I tap it on the side of the tang, not the side of the tail. This will ever so slightly press that side of the outside washer inwards, changing the angle.

Was that explanation understandable?Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

01-18-2015, 03:33 PM #7Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1185

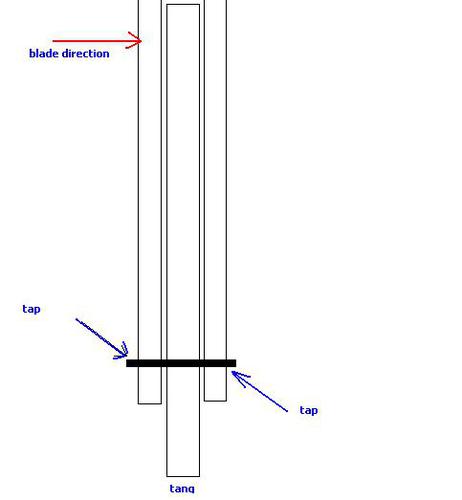

I made a little sketch here showing the pin method. The idea is to tap the pins on one side to drive the blade the direction you want. If your pinning is not all that perfect then this may be your problem. You just tapped too much on 1 side. If you bend the pin then you will have to do it again. It will move back and forth when you open the blade all the way and then close it.

Both tap locations marked in blue are to get the blade moved in the direction indicated.

Tap the other sides to move the blade the other way.Last edited by 10Pups; 01-18-2015 at 03:35 PM.

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

-

01-18-2015, 03:47 PM #8Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Polish and smooth the pin, with a 4-6 in piece of chop stick with a dab of polish, diamond or rubbing compound on the edge of the stick and chucked into a drill press. Use slow speed and lite pressure.

Masking tape over the scale and cut around the pin and washer will protect the scale if you slip.

-

01-18-2015, 03:48 PM #9

All great tips.

The only one not mentioned is, IS THE BLADE STRAIGHT?

It could be slightly warped to start off.

Lie it flat on one side note gap, flip it and note gap. Should be about the same.

Next step is pre-assembly using those tiny screws.

You can save yourself lots of headaches by mocking up the assembly FIRST!

Ed

-

The Following User Says Thank You to Chevhead For This Useful Post:

Euclid440 (01-18-2015)

-

01-18-2015, 03:58 PM #10Senior Member

- Join Date

- Feb 2014

- Location

- Florida panhandle, near Ft. Walton Bch.

- Posts

- 247

Thanked: 23

Very understandable. I also found a that was recommended here as well that agreed with your theory.

This is the quote.

Pin Adjustment

If you want to avoid unpinning your razor or you feel the alignment is only slightly off. Some issues can be corrected by doing a minor Pin Adjustment. This adjustment is simply holding the razor over a hard surface and using a tablespoon or peening hammer, striking the pivot pin in order to cause the scale (should say blade?) to adjustment away from the scale it is contacting (This method can also be used tighten up a loose scale).

You don't need to strike the pin very hard, you do not want to risk bending the pin or accidentally hitting/damaging the scales. A good test for how hard to hit the pin, is to hit it no harder then you would your finger... Seriously put you finger out on the anvil and tap the spot right at the cuticle and fingernail that real sensitive spot... If it hurts your finger you are tapping to hard...

I found this in "http://straightrazorpalace.com/srpwiki/index.php/Blade_Centering".

I did this and it worked since it was only slightly off. Now the blade edge looks centered and when I close the razor all the way both sides of the spine area hit both scales at the same time. Thanks for the help.

Now to smoothing the pins. I like Hirlau's idea of drilling a hole in a piece of aluminum to place over the pin to protect the scales. For the supplies I need to run to the store and get a can of Coke.

Jack

49Likes

49Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote