Results 21 to 30 of 48

Thread: A ? or 2 on Evapo-Rust.

-

04-11-2015, 10:40 PM #21

-

04-11-2015, 10:43 PM #22

-

04-12-2015, 12:47 AM #23

I was stricken with this same exact thought today, while stumbling my way through Harbor Freight! The wife sent me there to pick up another of the cases I'm now using as a dopp kit, for her makeup.

Saw the ultrasonic/vibrating cleaners & thought of using either Evapo-Rust or Ballistol.Decades away from full-beard growing abilities.

-

04-13-2015, 09:46 PM #24

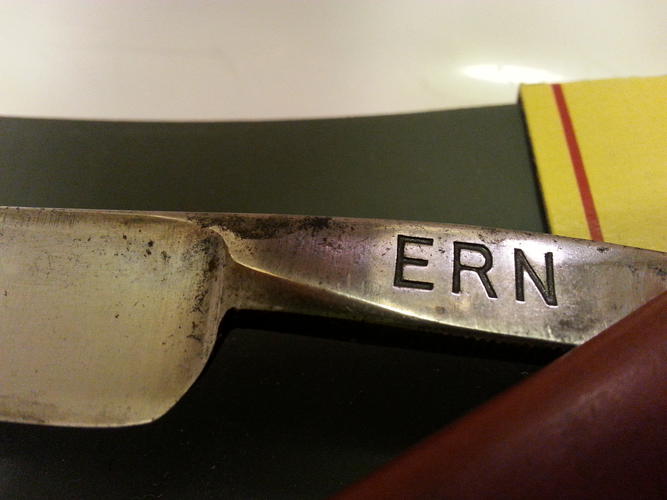

How about scales? I know the bottle says "safe on blah-de-blah, etc." I want to start cleaning up two project razors, but don't want to screw the pooch by trying to unpin them. The first razor to get the dip is the ERN in my photos. The scales will eventually be tossed anyway. So I suppose I will run this experiment either way lol.

Decades away from full-beard growing abilities.

-

04-13-2015, 11:14 PM #25

OK all

did a bit of a test with the EvapoRust

left some blades to soak for 3 days

each arvo I checked them & gave them a very light rub with 2000 grit W&D (no steel wool here which may be better) to remove the black film that builds up

after the 2nd day no real improvements to the better steel but bit more on a heavy rusted spot of 1

the Celluloid scales were not affected and cleaned up a little bit also

So now I have 2 horned str8s ( 1 black & 1 honey) soaking 3 days tonight

only problem was the after the first day I had the scales out of the juice & they distorted due to 1 scale being part submerged & the other not fully

so last night fully submerged both again to see how they go will report on that tomorrow

My conclusion

- the EvapoRust only dissolved the rust & has had no effect on the good steel which is great

- tarnish / Patina nearly wipes of with a cloth

- Celluloid scales are not effected at all & did not stain then & did help clean the grime of them a bit easier

- Brass scale inlay on a GOTTA was not effected

- can't say the same for the GOTTA's gold wash it was gone after the looking at it with the 2000g but was expected & fairly well gone to start with

- lead wedge was not effected & cleaned easier

- Brass & Nickel silver washers where not effected & the steel washers cleaned up same as the blades

- horn soaks it up if left for long periods, even after a month plus soak in Neatsfoot oil, but for short 1 hour soaks were OK

haven't tried Bakelite, bone or acrylic to date

as always YMMV

I will try to remember to take some post clean photos of the blades to compareSaved,

to shave another day.

-

-

04-14-2015, 07:23 PM #26

ERN Experiment.

ERN Experiment.

Before the soak. Wiped it off with paper towel, then steel wool (0000 grade).

Decades away from full-beard growing abilities.

Decades away from full-beard growing abilities.

-

The Following User Says Thank You to Crawler For This Useful Post:

JP5 (10-31-2017)

-

04-14-2015, 07:43 PM #27

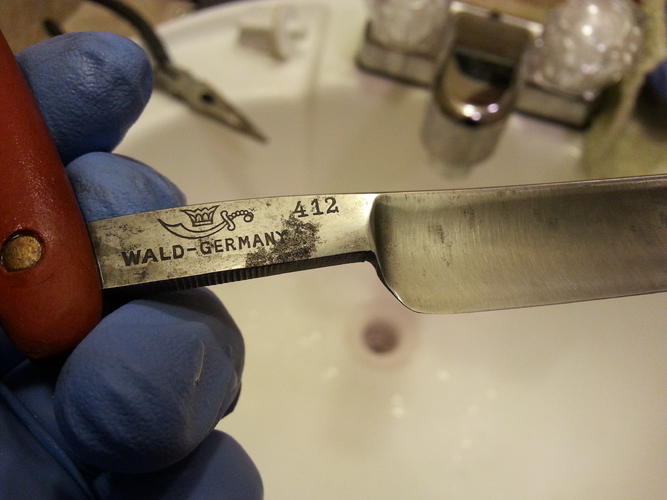

After 8hrs, sloshing every few hours in the cleaned Gatorade bottle repurposed for this project. Used steel wool again, a bit of 2k grit w&d sand paper on the spine, and one of those detailing wire (maybe stainless steel) brushes in choice spots.

Obviously, still a bit moist. Definitely going back in the dip. Probably won't check it till after work tomorrow.

P.S. The pliers were to retrieve the razor (by the scales) without pouring out the Evapo-Rust.Decades away from full-beard growing abilities.

-

The Following User Says Thank You to Crawler For This Useful Post:

JP5 (10-31-2017)

-

04-16-2015, 03:09 AM #28

A cheap way to keep the evaporust swirling around in a container is to use a cheap aquarium bubbler without the filter on it - just a plain plastic tube ending.

Some people never go crazy. What truly horrible lives they must lead - Charles Bukowski

-

04-17-2015, 06:57 AM #29

Okay, so I was too busy to even shave, let alone mess with the razor soaking in the Evapo-Rust. Good thing it doesn't harm, well, anything as far as I can tell. So I finally got around to it after about 57hrs. In the pics, I only rubbed one side with steel wool & the 2k paper, to show before & after of rubbing the grey stuff off. Rinsed and dried it before the pics, also.

Not rubbed yet.

The big rust spot came off with the more aggressive wire brush.

Left side got steel wool, the right/toe end got 2k paper. See the color difference? Seems the scratches from the paper are more uniform, but the steel wool conforms to the shape better.

My de-rusting container. Not as easy access as Substance's, but there is no worries about spills.

Finished pulling the wool over the ERN's eyes, rinsed, dried, and left it open to air dry for most of the night. The scales, whatever they are made of, got rather soft. Stuck it back in, and will check again tomorrow... later today, after work.Decades away from full-beard growing abilities.

-

04-17-2015, 08:10 AM #30

I got some of this to try out. Anyway I put some in a glass jar and put a garbage blade in for about an hour and the solution only came up to the tang and after I took it out and rinsed it off I noticed that where the solution came up on the razor it created a pit line around the tang. Make sure you submerge the entire item in the solution. Not sure if the air at the surface reacting to cause the line or not.

50Likes

50Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote