Results 41 to 48 of 48

Thread: A ? or 2 on Evapo-Rust.

-

05-05-2015, 12:37 PM #41

I've gone down as low as 625 grit sandpaper, using just edges of the paper and small sections just pressing using my fingertip to get all the gunk off. If there are some deep areas, 625 grit, 1k, 2k, 3k, and a final polish using 4k sandpaper.

Try using the lower grit, use your index finger on a small section of paper, and attack each of the spots until they are gone, then go up the progression. I took a De Pews razor to mirror finish by doing that, with lots of soaks in between. I think the Evapo-Rust, since it basically is safe for scales and only going after rust, is by nature going to be a slow process.

-

05-05-2015, 01:52 PM #42

Don't bother with the vapo-rust? It seems you've begun sanding to deal with the rust. When I first tried it I had the idea it would draw out the black from the pits, but it just doesn't get the job done. After days of soaking there is little improvement. My thoughts are that it just doesn't work well on black rust.

Than ≠ Then

Shave like a BOSS

-

06-15-2015, 04:34 PM #43Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

I use Evapo Rust to stop rust in heavy pitting, like at a pivot where you cannot get at it all, or in deep pits where I do not plan on removing the steel around the pit.

You still have to sand, buff or polish, it just stops the rust.

I start with 600 and work up to 1 & 2K with paper or the buffers and greasless. 600 grits scratches are easy to remove.

-

06-15-2015, 06:51 PM #44

-

01-01-2016, 03:57 AM #45

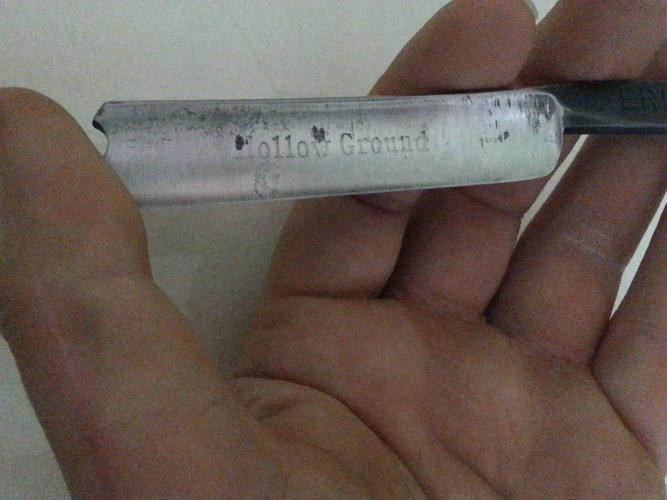

Made some progress. Not so much with the Evaporust, as I haven't messed with it since the update above. Been a lot of time spent hand sanding. Dropped all the way down to 220 grit of cheap harbor freight w&d paper, just about with the 3M 320 paper on most of the blade. Pretty much at a stopping point, until I reinforce the etch.

Pics...

Notice the residue still on the tang.

I'm a bit proud of how the backside turned out.Decades away from full-beard growing abilities.

-

01-01-2016, 07:23 AM #46Previously lost, now "Pasturized"

- Join Date

- Oct 2005

- Location

- Winnipeg Manitoba Canada

- Posts

- 1,333

Thanked: 351

Mechanical abrasion removes corrosion and pitting. Chemical treatment stops the corrosion and removes the harmful bits, but leaves the pitting and harmless components behind, requiring abrasion to remove it.

If you are going to restore a steel *anything* NOW, go ahead and just use abrasion.... It's needed, no matter what. If you intend to restore something "later", a chemical arrest of the corrosion is a sound move, so bring out the Evapo-Rust or vinegar (acid), followed by a thorough rinse and oiling. Both chemical methods work just fine, it's your choice as to which one you use... just make sure you rinse away the acid if you go that route. Neutralizing it might not be a bad idea either, just before the final rinse (I'd use some kind of soap, it's a base that neutralizes acids). Vinegar is cheap and handy, naval jelly is less available and less cheap in most cases, but it does come in a more viscous mix.

Regards

Kaptain "You pays your moneys and you takes your choices" Zero"Aw nuts, now I can't remember what I forgot!" --- Kaptain "Champion of lost causes" Zero

-

01-01-2016, 07:27 AM #47

Absolutely - I always give a tertiary cleaning and sanding to loosen everything up, then into the Evapo-Rust bath, makes everything much easier and cleans the blade up nicely. Just make sure you completely immerse it, it can leave a perfect line across any part that isn't submerged, crazy to get rid of.

-

01-01-2016, 11:12 PM #48

50Likes

50Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote

. Any thoughts or suggestions?

. Any thoughts or suggestions?