Results 11 to 20 of 23

Thread: Collarless pins and horn

-

06-11-2015, 06:12 AM #11

So, went to a local jewelry supply, no nickel silver rod but they did have half hard silver wire. The silver wire worked just fine and appears to be hard enough to hold even with the rigors of honing. I on the other hand need practice. The pins look like poo. They're a little wonky and ended up far too large. I need to to redo the wedge and add a little more taper so at least I'll have another go. On the plus side I believe the horn will be fine but I can see why you don't see it on horn as it was considered cheap and common. I'll let you guys know how to do it as soon as I can match the pinning job on my ivory Heljestrands.

-

06-11-2015, 11:04 AM #12

This John Barber has brass pins without collars. They are the original horn scales. It is 182+ years old. No cracks or splits in the horn.

-

The Following User Says Thank You to karlej For This Useful Post:

jfk742 (06-13-2015)

-

06-11-2015, 01:24 PM #13

I watched the video and it looked like the carbide post was not exactly anchored to the brass ring.....I guess I'll look at it again but I was waiting for a vice to hold the brass before he pulled the drill press down....dude knows what his is doing but it looked wonky. The results looked sweet and the knife kind of looked like an Italian switchblade....."when you're a Jet you're a Jet all the way, from your first cigarette to your last dying day."

"Call me Ishmael"

CUTS LANE WOOL HAIR LIKE A Saus-AGE!

-

06-11-2015, 02:25 PM #14Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

If you use a spinner, you still have to peen or mushroom the rod ends first, or they will not grip the scales, especially if you have made the holes a bit wider than the rod, which you should do to prevent cracking from differential expansion. So, you need a spinner that is wider in diameter than the rod you are using, or one with a deeper 'mouth' that will sit down on the peened end. Only trouble with the later method is that the rest of the metal mouth of the spinner may contact the scale and mark it.

You can get these (though they are not called 'spinners' - something like cup-end bits for finishing the ends of bead-making wires) from jewelry tool outlets and places that sell Foredom tips.

If you are going to widen the hole for the pin (which you should) then a tapered hole is fine as it follows the bulge in the rod caused by peening it, but you can bore it all the way through with a slightly (very slightly) wider drill bit.

I have seen this style of pinning used on vintage razors - Ern springs to mind, but never with horn. After centuries of using horn as a scale material I guess they must have used the method, but spreading the load of the pins holding the scales tightly together by using a washer undoubtedly proved more popular.

You have to ask yourself what is horn likely to do as a bad case example, eg:

1. It can be brittle enough to crack and split at the point of impact.

2. A small point source of impact can cause it to delaminate.

3. It shrinks and expands - a tight fitting pin can crack it when it shrinks.

3. If it is too dry it may delaminate and or crack, so make sure it is oiled (neatsfoot) first

and so on.

I hope it works out well for you, though!

Regards,

NeilLast edited by Neil Miller; 06-11-2015 at 02:44 PM. Reason: typos

-

06-11-2015, 03:47 PM #15

I have found good half hard nickle silver for pins at an old hobby shop. Two lengths for under five bucks. I bought some nickle silver brazing rod and it was too soft to work as pinning material, they bent easily. K&S brand used to carry them, but they do not show in the catalog now..

Amazon has some from a knife shop. I do not know the hardness of them though.

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

06-11-2015, 04:14 PM #16Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Have done alot of Ivory re-scales in Ivory with never a crack.

I anneal any rod material I use,than with a slightly oversized bit to cut a tiny chamfer in the material,works for me.

Lots of ways to do this.CAUTION

Dangerous within 1 Mile

-

06-13-2015, 06:02 AM #17

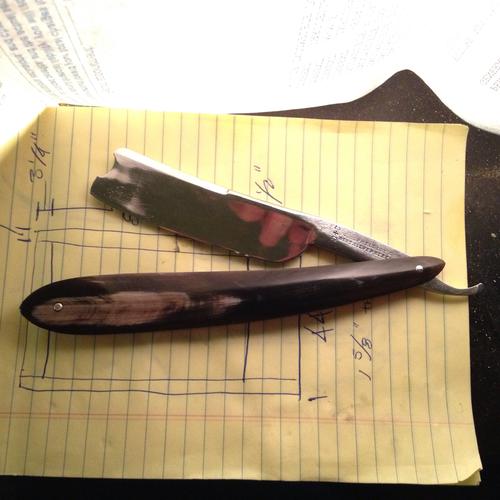

Ok guys, I think I got er done.

When I first saw a heljestrand mk31 with ivory scales I was in love. IMO they are the most well shaped scales. To look at them is one thing, but to touch them, to hold them in your hand.... So sweet! Unfortunately they cost a newborn for one in good shape. Anyways it should be apparent that is the look I went for.

So after three practice tries on a finished set of scales(don't do that, I'm just a glutton for punishment), I'm satisfied.

What I learned:

If you think the pin is too long, it is, file it until it's right, don't hit it until it "fits". You end up with a bent pin... Duh.

Hit the pin, a lot, but not hard, it will bend the pin

Hit the pin everywhere except on the center of it. When you flip it over and tap the otherside it will flatten it for you. If you hit it in the center it will flatten too much and look like poo, just like a big fat roundish silver poo.

Patience, lots of it. Just like every aspect of this hobby, you need it in spades.

Lastly, thank you so much for freely sharing your experience!

I feel like the pins should hold great as long as the horn doesn't delaminate or cup.

One more thing about lead wedges. You seasoned guys may have already discovered this. After pinning the wedge end I used a toenail clipper to cut off the excess then a file to get it close, then finished it off with sand paper backed with a piece of wood. There were still a couple little gaps where lead and scales didn't perfectly mate. As I was on the buffer trying to get the gloss back onto the edges I decided to buff the wedge perpendicular to the wheel. The wheel pushed the lead into the gaps and and now it looks perfect. Anyways hope this helps someone struggling with that same problem.

-

The Following User Says Thank You to jfk742 For This Useful Post:

Euclid440 (06-13-2015)

-

06-13-2015, 07:11 AM #18

Neil, I did drill the holes out to 5/64. Fingers crossed as the seasons change that the scales don't explode.

I do feel like I got the pins to curl enough that it's holding the scales down instead wedged tight inside the hole where the pin flares, at least that's the way it appeared when I unpinned them time before last. I do have another Elliott that I want to make a matching set of scales for but in just black horn.

-

06-18-2015, 06:23 PM #19

[QUOTE=karlej;1507193]This John Barber has brass pins without collars. They are the original horn scales. It is 182+ years old. No cracks or splits in the horn.

I don't know if it's just me but do I see traces of what was a collar under the head of that pin? I'm not doubting that collarless pins wouldn't crack the horn but it would most likely have to have a tapered hole in the scales I would think.

I have some 1/16" drill bits (.062") plus I have some just a tad larger (.077") which work perfect for pinning & I have never broken a set of scales yet using the .077" drill bits which I found on the bay or any machine shop supply or some tool companies might have them.

-

06-19-2015, 05:30 AM #20

Nope, no collars. Just used a 5/64" bit. If I were to do it again I would opt to use 1/16" bit and chamfer the hole.

I still need to screw around with it as I can't seem to replicate my heljestrands. I need to visit my cousin and see if he can't make me a spinner of sorts in his shop.

37Likes

37Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote