Results 1 to 10 of 16

-

09-28-2015, 07:02 PM #1Senior Member

- Join Date

- Feb 2015

- Location

- Duluth, GA - Atlanta OTP North

- Posts

- 2,546

- Blog Entries

- 1

Thanked: 315 Trouble Making Domed/Support Washers

Trouble Making Domed/Support Washers

Well, I'm tried making a 'press' for domed washers using two larger bolts (like I've seen in another thread), but it hasn't gone well. The bolts I bought are too hard to drill and it is difficult to keep the bit centered. I bought some brass ones too, but I looks like they were just plated.

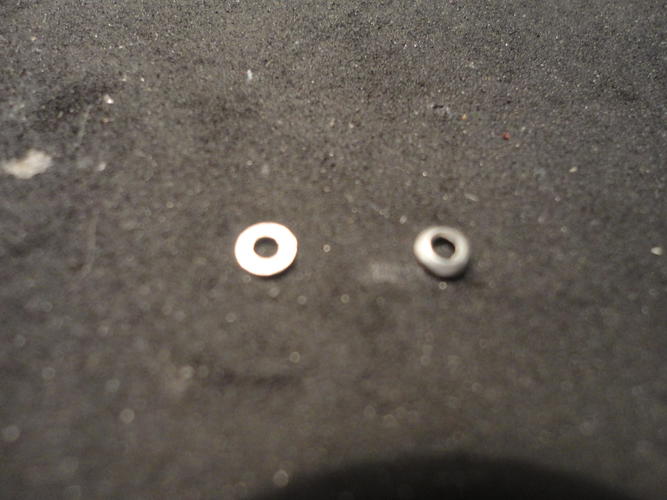

I've read about using a dapping block, but it seems like the washers with the flat ring at the bottom would be less prone to flattening. Any suggestion??

I have some pivot washers I was going to use (#0 or #00? I think), but what washers do you use to make the larger domed washers?? Or do you have to punch them out yourself??

Thanks

-

09-28-2015, 07:57 PM #2Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

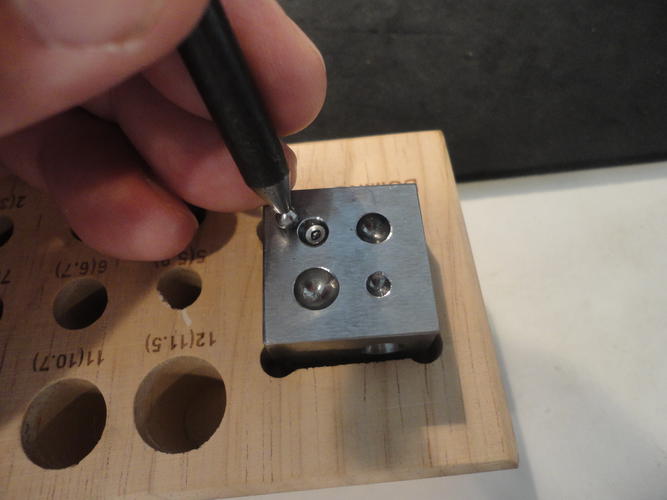

What I did was made a dimple in a piece of steel, a piece of railroad track. I used a rotary tool with a round tip burr. I drilled a small pilot to make it easier to start straight then made the dimple. I then took an old drill bit that was the right size around. Basically I too the outside diameter of my washer and subtracted two times the thickness. I then broke the spiral off of the bit and rounded that shaft so it fix well into my domed dimple. Put the washer in position and hammer it down with the drill/punch. It is very simple and effective.

It's not what you know, it's who you take fishing!

-

09-28-2015, 11:51 PM #3

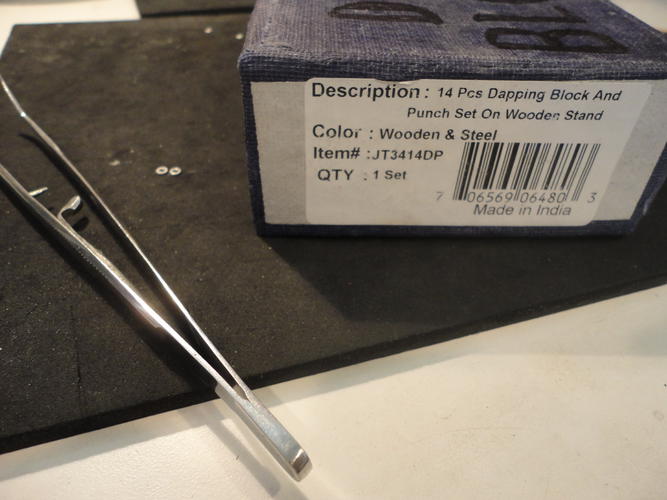

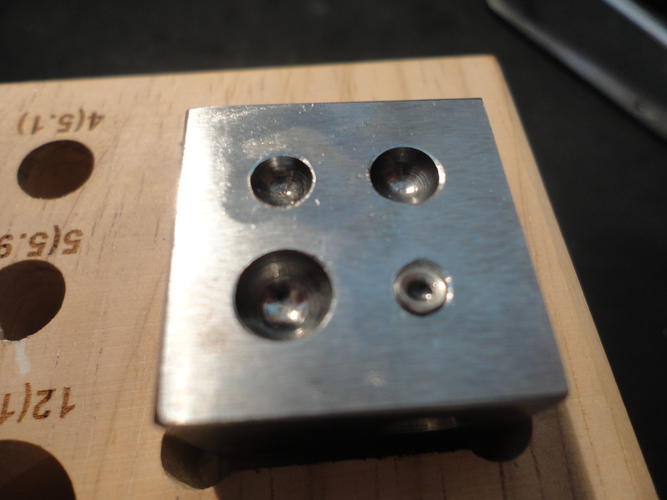

A dapping block set is just the thing for doming washers. Available on eBay and Amazon. Small sets aren't very expensive. I like the .062x.188x.015 washers for this. Put a #0 steel washer under it and you will not flatten it during pinning.

I use the same brass washer for pivot washers but they are too thick right out of the package IMHO. I flatten the on my vise anvil with a hammer. A few hits and you'll have it down to .007 or so which is about right. The hole usually closes up some so I use a small tapered pin reamer to open it back up again, then rub it on some 320 grit paper to take off the burrs.

Good luck

-

09-29-2015, 12:16 PM #4

My service is good, fast and cheap. Select any two and discount the third.

My service is good, fast and cheap. Select any two and discount the third.

-

09-29-2015, 12:38 PM #5Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

A tapered diamond burr, from Harbor Freight ($8 for the set) in a pin vise will open the hole nicely. Also works well for tapering the hole in the scales to prevent cracking, when pinning.

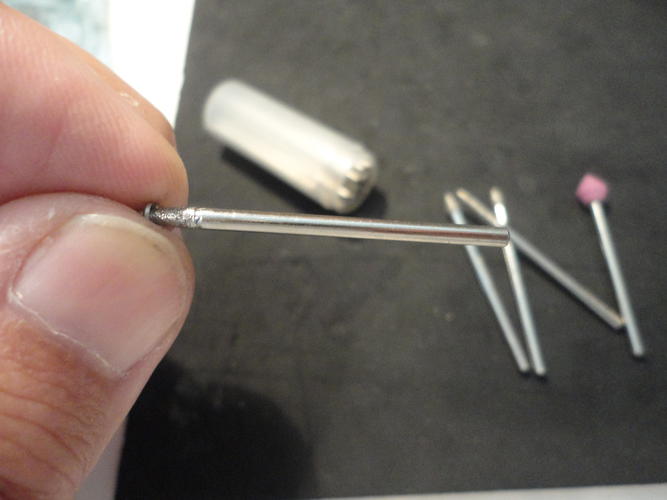

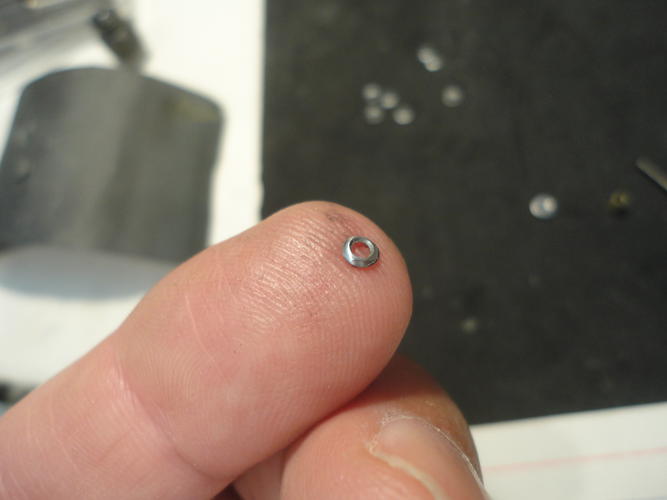

Here is a pictorial tutorial on making domed collars. I also made a mandrel from a bolt and small piece of brass tubing to polish them.

Last edited by Euclid440; 09-29-2015 at 12:54 PM.

-

09-29-2015, 12:44 PM #6Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Here’s the polishing mandrel, just a bolt with the head ground down a piece of 1/16 in id brass tubing and nut.

Polish with metal polish and Chrome Oxide.

Last edited by Euclid440; 09-29-2015 at 12:55 PM.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

Slawman (02-10-2016)

-

09-29-2015, 12:58 PM #7

That's great Euclid - I'd already used your method of a mandrel for polishing - I now need to find those tapered burrs - we don't have HF over here.

My service is good, fast and cheap. Select any two and discount the third.

-

The Following User Says Thank You to UKRob For This Useful Post:

Euclid440 (09-29-2015)

-

09-29-2015, 01:14 PM #8Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

I then take a 4-5 inch piece of bamboo chop stick and dimple the end so it fits over the pin head,( just a bit smaller) of the pinned razor.

Put a dab of .5 Diamond paste, rubbing or polishing compound on the tip, chuck in a drill press and polish the pin head smooth. If you make the dimple just the right depth, you can polish the pin and the washer at the same time. Finish with Chrome Oxide and metal polish.

A block of wood with a dimple drilled in it to hold the pin on the other side, keeps it from dancing on the table, or a piece of 6mm foam.

Chopsticks are handy, I always pick up an extra set.

-

09-29-2015, 01:28 PM #9

So how are the domed washers oriented with regard to the shank and the scales?

Striving to be brief, I become obscure. --Horace

-

09-29-2015, 01:44 PM #10Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Peened dome side up, either to fill the hole or domed over smooth.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

globaldev (10-02-2015)

15Likes

15Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote