Results 11 to 17 of 17

-

10-08-2015, 03:35 AM #11

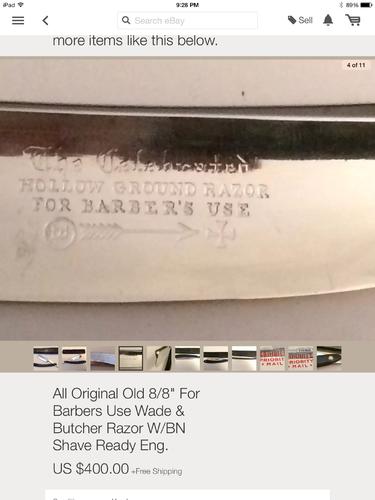

So this is an example of the higher end sell of this WB

So this is an example of the higher end sell of this WB

And I notice that it is mirror imagine? Is this what people are looking for, personally I would want some of the etching to remain...

-

10-08-2015, 03:42 AM #12I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

That kind of finish can be achieved with hand sanding and final buff with polishing compounds.

I have done it a few times and the progression goes something like that, for me:

sand

paper

grit

600

1000 + 1.5k SiO powder

1500 + 1.5k SiO powder

2000 + 2k white alumina powder

2500

3000

4000 +10k white alumina powder

6000

8000

white buffing compound, CrO buffing compound.

If the sanding job is quality the blade will be almost perfect mirror. The etch stays almost untouched.

With your blade if you do a similar progression, you will still have a bunch of pitting left but the etch will be mostly intact.Stefan

-

10-08-2015, 05:37 AM #13

So what the common theme I see here is going light on this blade, first mothers mag and see what will polish off and see what I'm dealing with in terms of issues with the blade... Then on to some high grit sand paper and hand sanding the razor to an extra fine grit... Then onto the buffer...

-

10-08-2015, 05:40 AM #14

-

10-08-2015, 05:49 AM #15Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,450

Thanked: 4829

I do most of my work by hand sanding. Yes it is time consuming. There are a few things about using a buffer. hey have a learning curve so when you get your greaseless compound you should also get a bunch of really rough and likely already dead razors for practice. It is pretty likely that you will wreck a few blades on your journey. The one thing that I see fairly consistently is that people that are not great on the buffer tend to blow out all the subtle line on the blade. They simply get all rounded out. The web is full of great examples of what not to do with a buffer. I find it perfectly acceptable that a 100 to 200 year old razor has a few beauty marks here and there. Honestly I have tried quite a bit to try to imitate patina so I can get rid of all the corrosion on a blade and have it look like it has been loved and cared for for the it's life. I have not completely gotten there. I do have a beauty that looks like that naturally. I cannot find a picture of it.

It's not what you know, it's who you take fishing!

-

10-08-2015, 11:26 AM #16Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

I agree with Shawn on the buffing, the razor pictured has been over buffed, most of the etch is gone on the blade, as is the detail of the razor, the scales are also not well made, shaped/ rounded and finished, the pivot hole is also not centered. They are too narrow for the razor, doubtful it will hit the asking price.

Steel wool will get it clean, 600 will tell you how much pitting you have and then you can decide how much sanding to do or if you want to live with some pitting. 600 will not remove the etch, if you go light with the pressure. Original scales are better or at least use them as a template.

Here is a proper restoration, by Wolfpack34, look up some of his work, he posts a lot of fine Sheffield restoration. Check the Custom builds/restoration forum.

Compare Mike’s detail work to the one you posted. Note tang stamps and the scales, night and day.

Mike’s satin finish is some of the best work I have seen. Here is a satin finish blade with polished tang. Mike does most if not all his work by hand, hours of hand sanding to retain all the detail, you can never put steel back on.

Last edited by Euclid440; 10-09-2015 at 02:56 AM.

-

10-08-2015, 11:40 AM #17I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

Sadly I got it a few years ago and can't remember where from.

I think this is similar

http://www.ebay.com/itm/Green-Chrome...3D262041210729Stefan

16Likes

16Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote