Results 1 to 10 of 31

Thread: Cracked Edge

-

12-25-2015, 09:32 AM #1

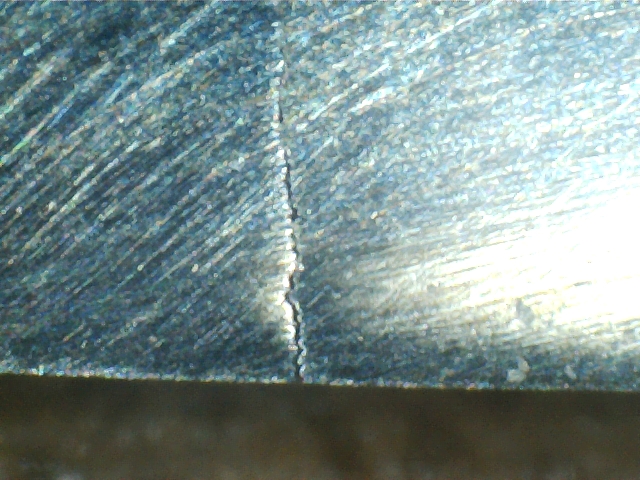

Cracked Edge

Cracked Edge

My restoration project has come to halt due to a crack , just over 1mm tall , 4mm from the tip and I need a bit of advise please.

I figure that to start off I should breadknife the edge. It would ensure even metal removal along the entire edge. Even though the crack is at a part of the tip that starts turning upwards.

Also honing at any other angle apart from 90 degrees may cause the crack to lengthen .

What I'm not sure about is what hone to start on.

I was going to use the Shapton 500k but now I'm thinking should I use a Atoma 1200 , I have a new ish one and a worn one. I also have a DMT 325. The problem with that plate is that there is a cluster of diamonds that even after much effort haven't been able to sort out..

I've never took a blade to a diamond plate before so im a little bit dubious .

Thanks

-

12-25-2015, 10:47 AM #2

-

The Following User Says Thank You to rolodave For This Useful Post:

JOB15 (12-25-2015)

-

12-25-2015, 11:42 AM #3

sweet Jesus...

I did ask a pro and he said I could just hone it out?

1 and a half millimetres may not sound like a lot but it actually is in relevance to an edge.

The blade is defiantly thick enough to cope with getting some shaved off.

-

12-25-2015, 12:52 PM #4aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

Yep, it's going to require being shortened. You could re-profile it just as it is now or a whole new identity...but that toe is going to have to go.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

The Following User Says Thank You to ScottGoodman For This Useful Post:

JOB15 (12-25-2015)

-

12-25-2015, 04:47 PM #5Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,455

Thanked: 4830

I have a Frederick Reynolds that had been reground into a half hollow. The regrind had been done a very very long time ago and the blade had a lot of deep patina. As I cleaned it up I noticed the crack by the toe. It lined up almost exactly to the bak of the notched tip. I removed the tip at the crack and then re-profiled it. It turned out well and shaves well, looking at it you would never know it have been modified. As you start to hone they crack out if it starts to move at all stop and cut off the blade. It is fix-able it may not finish the way it starts.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

JOB15 (12-25-2015)

-

12-25-2015, 05:40 PM #6

JJ, you sure it's 1mm. The more I look at the pics the more I think it's more as 1 mm is really small. In any case if it can't be honed out for whatever reason then you only have 2 options. Either shorten (B)and grind a new barber's notch (or deepen it) or option A. You've already spend an exuberant amount for that razor so just trying to find the cheapest route which of course would be to carefully breadknife the front side of the edge and slowly try to hone it out doing circles but again it all depends the size of the crack and honestly you're the only one that can really judge the crack as pics can be deceiving. If you don't feel confident or are afraid the crack to worsen by doing it yourself then send it out and spend your christmas bonus on it

Last edited by Maximilian; 12-25-2015 at 06:58 PM. Reason: typo

əˌfisyəˈnädō | pərˈfekSH(ə)nəst | eS'prəSSo | düvəl ləvər

-

The Following User Says Thank You to Maximilian For This Useful Post:

JOB15 (12-25-2015)

-

12-25-2015, 06:03 PM #7

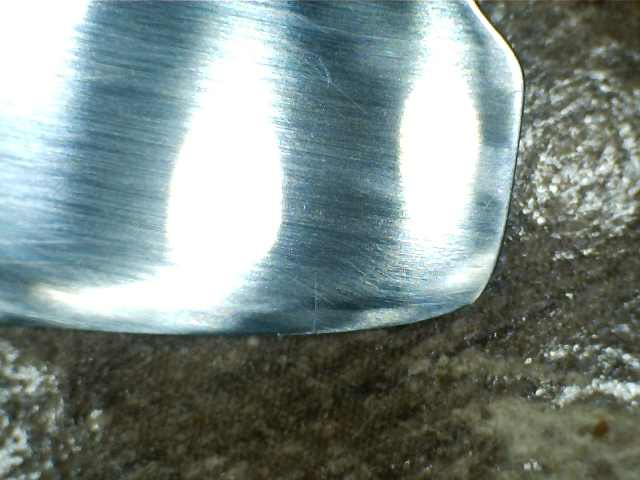

With a little effort you can grind the toe down and create your own look on the toe. That crack looks bit bigger than 1 mm. With the right tools and patients it can be done in a few minutes.

I had a chip on the toe of this razor that was a square point. I reground it to look like this.

"The production of to many usefull things results in too many useless people."

"The production of to many usefull things results in too many useless people."

Karl Marx

-

The Following User Says Thank You to Suticat For This Useful Post:

JOB15 (12-25-2015)

-

12-25-2015, 07:05 PM #8

Its is 1 and a half mm.. I have measured it a few times because it looks more in the pictures..I would like to send it to you for re grinding , I don't really care about money . It's just digits on online banking that change and move about

In saying that though I think the best option if for me to hone out "A" . Should be ok, I hope.

I'd rather save you for a full restoration down the line.. Get some of those cobalt burl scales and I'd like to judge your restoration skills

-

12-25-2015, 07:45 PM #9

-

12-25-2015, 09:49 PM #10illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

I realize this is heresy but...

Another option is to do nothing. I have several cracked blades that I have used for years that remain unchanged. In fact my most recent shave was with a Frederick Reynolds with two cracks. As long as the crack does not scratch my strop, I figure they won't scratch my face.

34Likes

34Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote