Results 1 to 10 of 20

Hybrid View

-

01-16-2016, 06:58 PM #1At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,203

- Blog Entries

- 1

Thanked: 13250

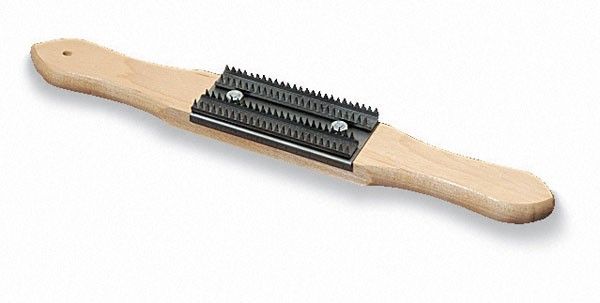

With a wheel rake

No seriously that is what you use

Keep in mind that raking is for Polishing compounds when they build up on the wheels, Greaseless compounds are designed to build up on the wheel

You need separate wheels for each compound that you use,,,

Try flipping the wheel the other way

Try speeding up the rpm when loading greaseless, the higher speed helps to "Melt" the compound on the wheel,, once the wheel has a coating then it gets easier each time

Just like everything else in this hobby there is a learning curve..

Caswell's has a pretty good info section also, shows a rake at the very beginning hehehe

http://www.caswellplating.com/buffman.htmLast edited by gssixgun; 01-16-2016 at 07:01 PM.

-

The Following User Says Thank You to gssixgun For This Useful Post:

Kees (01-16-2016)

-

01-16-2016, 08:57 PM #2Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Wheel rake,

Yes if you put greased compound on, it may not take greaseless as well, though I have never tried.

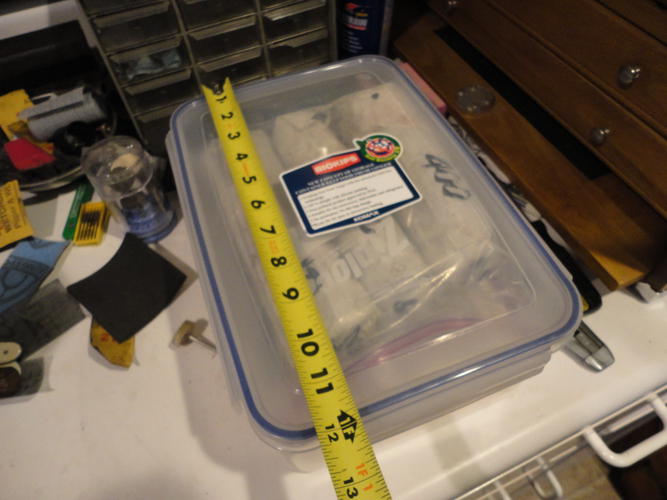

One compound per wheel, I use 2 wheels per grit, so one is always drying. And I mark the grit and the rotation on the wheel, donít know that it matters. Make sure your marking are above any washers or stiffeners that are in place when on the buffer, so you can see the direction and grit.

I use 4, 600 grit wheels, it is the grit I use most. And keep the 600 grit wheels in various loading for different application. BTW, a worn 600 wheel is great for cleaning jimps, will make them gleam like new, or for a light polish.

You must rake your wheels and trim, before each application of greased and a fluffed greaseless wheel seems to take greaseless better, mine are void of grit when I reload anyway.

Some say you can use a large screwdriver, to rake, but I think you are just asking for trouble, Wheel rakes are not that expensive and much safer, made for use with 2 hands, do wear breathing protection, fine fibers will be released. I also use a fan, blowing air and dust across the face of the buffer and away from me.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

Kees (01-16-2016)

-

01-16-2016, 11:05 PM #3

Caswell sells a wheel prep product called Glu-Tite Greaseless Wheel Prep. New wheels can be a bit tricky to get the first coat of greaseless to stick. This stuff will give the compound something sticky to stick to. Apply it sparingly. Once you get some compound to start adhering to the wheel over this stuff you will not need to apply it again. Like Glen said once you get the compound to start sticking it will go easy. When you've gained some experience you may find you do not need the Glu-Tite to load a new wheel.

Good Luck,

KarlLast edited by karlej; 01-17-2016 at 12:39 AM.

-

The Following User Says Thank You to karlej For This Useful Post:

Kees (01-17-2016)

17Likes

17Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote