Results 1 to 10 of 17

Hybrid View

-

01-16-2016, 05:15 PM #1Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

[QUOTE=hatzicho;1589902] The first patent was registered in 1908 by Carl Friedrich Ern, the famous Solingen razor grinder and developer of the double hollow grinding machine called “Hexe” (witch) that revolutionized the razor manufacturing in the early 20th century.[/FONT]

One must wonder where he got this idea for the hollowing machine from... Wolferts grinding machine was well before this one. http://straightrazorpalace.com/works...ne-1898-a.html[QUOTE]Last edited by Martin103; 01-16-2016 at 05:18 PM.

-

-

01-16-2016, 05:39 PM #2

[QUOTE=Martin103;1589914][QUOTE=hatzicho;1589902] The first patent was registered in 1908 by Carl Friedrich Ern, the famous Solingen razor grinder and developer of the double hollow grinding machine called “Hexe” (witch) that revolutionized the razor manufacturing in the early 20th century.[/FONT]

One must wonder where he got this idea for the hollowing machine from... Wolferts grinding machine was well before this one. http://straightrazorpalace.com/works...ne-1898-a.html

Interesting - I didn't know the Wolfert patent. Thanks for sharing.

But the Ern patent I described above from 1908 belong to the honing machine, not the grinding machine. The double grinding machine was developped by Ern in the year 1893, so long before he developped and patented the honing machine. It simply took some time from development until the Solingen razor companies really accepted! and used the machine. Carl Friedrich Ern was a great grinder and developper but also disputed among the other Solingen grinders for his new ideas and methods. Therefore I wrote .. in the early 20th...

Regards PeterLast edited by hatzicho; 01-16-2016 at 05:48 PM.

-

01-16-2016, 06:05 PM #3

Well over the years I spoke to a lot of old hollow grinders and found three machines. Two of them are still in usage by the grinders, a third one hasn’t been used for years and stands in an old shed among other machines. Unfortunately, none of the people I met was willing to sell me his machine, also not the one who don’t use it any more. But the two people that still work with the machine showed me how to use it. And I found some more disks, mainly well used and washed out. Also some smaller disks, used for different machines.

Finally, at the beginning of last year I made a call by another german grinder of a younger generation. I didn’t expect to hear from him –yeah I have such a machine, you can have it, I don’t need it any more…..

Surprisingly he said exactly these words! I couldn’t believe it!

I met him a few days after the call. Of course, the machine was not in best condition. It was stored outside in an old shed, but the shafts move and the disks were intact and not broken.

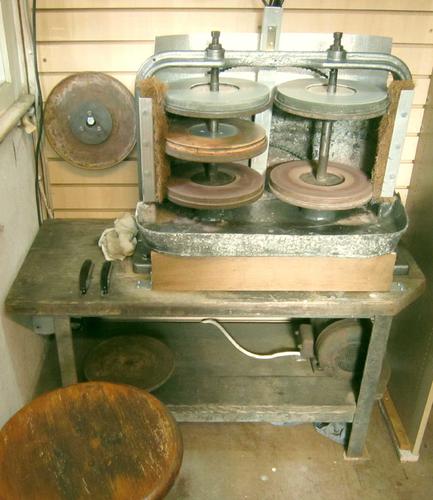

This was the first photo he sent me from the machine:

The big surprise was, it was a machine normally carrying 2x3 disks. Only one shaft was equipped with three disks though and it was not a blue thuringian, but another fine stone. First I thought it might have been a coticule, but it is too hard. So it should be a fine artificial stone, some kind of early ceramics. I have some old benchstones from this material too.

The artificial stones for bevel setting are really coarse. The thuringians are natural combination stones blue/ yellow-green:

I spent a lot of time to restore the machine, but want to keep as much as possible from the old parts. So I didn’t make a new pan for example, but kept the old one and sealed it with water glass and epoxy. I made a new water distributer to all the disks and fixed everything else as good as possible and give it a new paint. Fortunately the motor was still running, I only had to exchange the belt-drives.

Honing on the machine is not an easy thing and needs much experience. You have to be very carefully. Metal is removed very fast – a least with the coarse artificial stones. Also it is not easy to keep the razors really flat on the disks, while moving them backwards, especially for the upper disks, when you sit in front of the machine. And at least - it is a relatively whet experience. I have mounted new water deflectors on the sides but still the water is skidding in your face, while you are sitting in front of the machine.

But beside this I cannot describe the fun I have while using the machine!

… to be continued…

-

The Following 20 Users Say Thank You to hatzicho For This Useful Post:

Badgister (04-29-2020), criswilson10 (01-19-2016), cudarunner (01-18-2016), eddy79 (01-19-2016), Frankenstein (01-17-2016), JimmyHAD (01-16-2016), Leatherstockiings (01-16-2016), mainaman (01-17-2016), MattCB (01-16-2016), MikeB52 (01-17-2016), Phrank (01-17-2016), RusenBG (04-28-2016), sharptonn (01-17-2016), Steel (11-04-2018), Substance (01-17-2016), Tack (01-17-2016), Thug (01-17-2016), tintin (01-17-2016), Walterbowens (01-17-2016), Willisf (01-16-2016)

-

01-17-2016, 02:31 AM #4

thank you for sharing. this is fascinating!

-

01-17-2016, 02:36 AM #5

Extremely cool! Thank you for sharing this!

"Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

01-17-2016, 03:13 AM #6

Agree with Tom, superb, thank-you for sharing this.

Can I send you some old wedges to turn into fine hollow ground blades?

-

01-17-2016, 10:40 AM #7

What an awesome story and find

keen for the rest of the instalmentsSaved,

to shave another day.

72Likes

72Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote