Results 1 to 10 of 14

Thread: High grit sanding drum for drill

-

01-17-2016, 10:32 AM #1

High grit sanding drum for drill

High grit sanding drum for drill

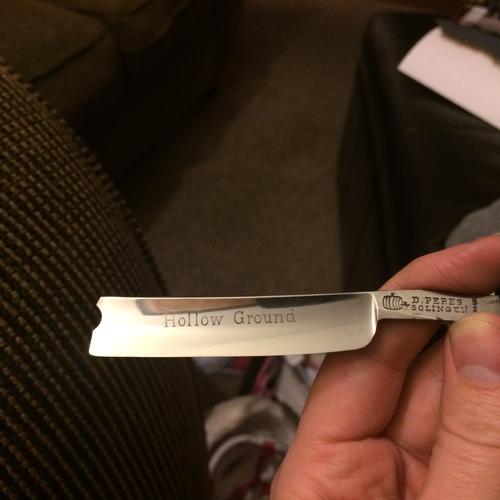

Been working on some etched blades lately. I like to hand sand them to keep the etchings sharp. I've been experimenting with this sanding drum and I'm very happy with the results. I've looked all over for high grit drum sleeves but I haven't found anything. I used some double sided tape and 1k wet dry on a rubber sanding drum. The blade I'm experimenting with had several scratches and some staining. The drum cleared them up in just a few minutes. The advantages here over hand sanding are 1. Way faster 2. Uniform vertical scratch pattern 3. Etching friendly. It's on a drill so you can keep the RPM's nice and low. I would guess I was going about 250rpm. The picture of the blade is about two minutes sanding and about twenty seconds on the buff with some green rouge. The blade was not bad to start with but I would have been hand sanding for much longer to get to this point. I'll finish sanding the spine and tang by hand, hit it with some Emory and finish with rouge. I've seen people doing similar thing for Dremmels but those are too small and to fast for my liking. I think next I'll do an 800 and 1500. I'll be trying those as a step between greaseless and Emory. Can anyone point me toward a commercial product that is similar to this?

Last edited by BeJay; 01-17-2016 at 10:41 AM.

-

-

01-17-2016, 11:18 AM #2

Love the look of this. I have a lot of problems with rsi type problems with my hands. I ignore it when hand sanding but suffer for days after this could be worth a try ��

-

01-17-2016, 12:04 PM #3Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Very nice work, I have not found anything commercially close to that grit, except paste.

Love those D. Peres razors, they are some shavers…

-

01-17-2016, 05:42 PM #4Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,450

Thanked: 4829

There was a guy some time ago souixchefdude perhaps that made one using a cork on a mandrel. I have a similar set up and put my drill in a vise. I use low speed high torque drill. I think my drill turns around 550RPM. I have found that if you cut the paper at a 45 it makes less of a bump when it comes around. Very light pressure and it does lighten the load. You really need to change the paper often.

It's not what you know, it's who you take fishing!

-

01-19-2016, 09:08 AM #5

Been working another blade on it and I really think I'm onto something here. The 1k does clog up pretty quick but if I keep it wet it last ls much longer. This blade was badly stained with lots of small black rusty spots. Not real bad, but I would not have hesitated to use 600 grit greaseless on it. I worked the face of the blade for about 10 minutes on each side. The pictures are straight off of the drum with no polishing. The spine has not been hand sanded yet and I still need to work the stabilizer area. The big bevel was already there and was not caused by sanding.

In my opinion this finish would be perfectly acceptable with a little hand polishing to finish it off. And that's at 1k. It wouldn't take much effort at all to go 1500 then 2k(maybe 5 min). Another advantage is that it won't soften lines the way that greaseless will.

I've been scouring the Internet and I think I found a good drum for this at woodcraft.com

They carry this in a few different sizes and it's made to use with paper(not sleeves). I'll be odering one to try it out and more if it works well. I'll also be looking for a good way to mount the drill or make a rig with drill parts. If I make my own rig I could add a water drip as well to keep the paper from clogging up. I can see this very likely becoming my preferred restoration method over greaseless and hand sanding. It's easier, safer and I love the initial results.Last edited by BeJay; 01-19-2016 at 09:23 AM.

-

The Following User Says Thank You to BeJay For This Useful Post:

outback (01-19-2016)

-

01-19-2016, 12:49 PM #6

Is there not perhaps an easier attachment method than double-sided tape.

With various grits being used, I can imagine that it becomes a royal PITA to remove the tape from the drum.Tony

-

01-19-2016, 12:59 PM #7

-

01-19-2016, 04:11 PM #8Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,450

Thanked: 4829

I have been very tentative. I cut my drum to 1 1/2 and to begin with it was an experiment to get a uniform satin finish. Changing the paper is not so bad. Even at the low speed I am running you can develop some heat, but it would take a while. Typically I use it wet and with 1K plus. It has the potential to really mess a razor up, many things do. We need to use caution when using power tools, especially when razor are involved. When I get back to restoring, if this thread is still active I will add some pictures.

It's not what you know, it's who you take fishing!

-

01-19-2016, 05:21 PM #9Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

There are several good videos on making sanding drum sleeves. But is a lot of work compared to your double stick taping wet & dry to a rubber drum. WD40 removes the glue easily.

Years ago I did try this on a drill press with decent results, but then switched to buffing.

I have since switched to a cordless, variable speed, flex shaft Dremel that runs slower than my corded ones. I will have to re try this with the flex shaft.

You could probably connect a flex shaft to your drill as well, really give you much more control and ease of access.

Nice thread.

-

01-19-2016, 05:29 PM #10At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,063

- Blog Entries

- 1

Thanked: 13249

BeJay

I have the full set from Woodcraft and they work really well if you can stabilize the drill and use 2 hands on the razor...

Somwhere hidden deep in this sub-forum is a Thread about it and even some plans that one of the guys did of a Drill mount.. I simply slide mine into a vice..

The best of course is to have an Adjustable Speed drill and a Reversing drill so that you have the most options..

You can simply cover the worn out drums from WC with your own Sandpaper the full set IIRC has 1/4 - 1/2 - 3/4 inch drums

the full set IIRC has 1/4 - 1/2 - 3/4 inch drums

-

The Following User Says Thank You to gssixgun For This Useful Post:

Hirlau (01-23-2016)

32Likes

32Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote