Results 1 to 10 of 12

-

02-28-2016, 03:09 PM #1Senior Member

- Join Date

- Jan 2015

- Location

- mountainside North Alabama

- Posts

- 129

Thanked: 14 protective coating for covered tang

protective coating for covered tang

This tang will be going back into a J Rodgers.

The original craftsman may have used heavy paper- it was so decroded I couldn't tell for sure.

The fit is a wee bit loose so I was thinking of a coating that would be rust preventive and thick. Like maybe multiple coats of rustoleum or some other product available at H depot or lowes etc.

The tang cover is proboscid tusk.

Any recommendations appreciated.

-

02-28-2016, 10:09 PM #2Senior Member

- Join Date

- Jan 2015

- Location

- mountainside North Alabama

- Posts

- 129

Thanked: 14

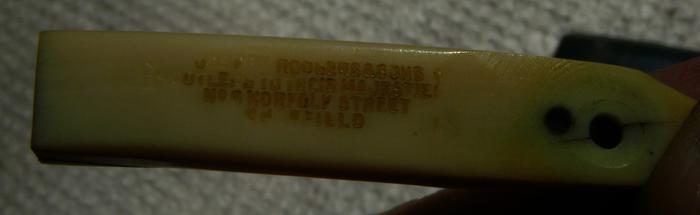

After cleaning these marks on the tang look uncannily like hardness tester footprints. Vickers hardness dates to 1921... hmmmmmmm

-

02-29-2016, 08:11 PM #3

That is pretty neat. Seems like a lot of tests in one spot tho. Maybe someone was bored at work that day?

I can't really think of anything wrong with rustoleum. Will it last long enough? Maybe just be extra careful with it, don't want to have to spend a bunch of time sanding paint off of a razor.

Best of luck, if I think of anything better, I will post

-

02-29-2016, 10:58 PM #4

I'm not sure exactly what they used, if anything, to coat the tang. I simply don't have any experience with covered tang razors. But if you are look for something to cover the razor's tang, as a layer between the steel and the decorative tang covering, I have a suggestion or two. This makes me think of, just off the top of my head, "Plasti-dip" and "Tool Magic". I think I've seen both of these in craft stores when I wander aimlessly while the wife shops... JoAnn Fabrics, Michael's, Hobby Lobby, etc.

Decades away from full-beard growing abilities.

-

The Following User Says Thank You to Crawler For This Useful Post:

KenG (03-01-2016)

-

03-01-2016, 06:20 PM #5Senior Member

- Join Date

- Jan 2015

- Location

- mountainside North Alabama

- Posts

- 129

Thanked: 14

I think I have a solution for the short term, anyway.

I will use teflon plumbers tape to snug up the fit and microfastener hardware to pin. Will try wax around the opening to keep water our during shaving. Will put up full pics when done.

Does anyone have an ivory tang cover with mfg writing engraved in it ?

-

03-01-2016, 08:35 PM #6

Sounds like a nice, simple, reversible plan. Sadly, I do not...

-

03-02-2016, 12:46 AM #7Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,465

- Blog Entries

- 1

Thanked: 4207

First pic is a little dark.

So the tang cover is still intact? You were able to remove it as one piece from the blade for cleaning and want to add an inner rust prove adhesive still?

I just redid a covered tang on a WB and used ivory and brass. I cleaned the inner tang completely rust free and used a clear slow curing 2 part epoxy to fully rebond the tang. then once cured all the surplus epoxy came off with fine sanding. Check the butchered blade thread, around page 384 for the results.

Those small drill divots could have been to improve adhesion grip on the original tang sides?

Good luck with it..

"Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

03-03-2016, 10:53 AM #8Senior Member

- Join Date

- Jan 2015

- Location

- mountainside North Alabama

- Posts

- 129

Thanked: 14 I say, whot !

I say, whot !

yes, got cover off without breaking. Incredible workmanship, at first I doubted it was ivory. I will put all pics up when done. I want to use it, so snug with Teflon tape and removable fasters should enable that.

-

03-03-2016, 03:30 PM #9

There.... looks like.... some goo? In that hole?

-

03-03-2016, 05:48 PM #10Senior Member

- Join Date

- Jan 2015

- Location

- mountainside North Alabama

- Posts

- 129

Thanked: 14

A happy form of goo known as antique or vintage goo. 1st hit with warm soapy water, then gently used pipecleaners to get the goo chunks. The main lengthwise hole, or tangway, penetrates both pin holes so i was able to coax the last of goo out thru them after pushing it down the tangway.

I have seen pics of other Rodgers like this with what appeared to be heavy bond paper or cloth to snug the fit. That's what gave me the idea for teflon tape. In this goo there were visible tiny fragments of some material for the snugging.

7Likes

7Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote