Results 1 to 10 of 23

Threaded View

-

08-05-2016, 10:27 PM #12

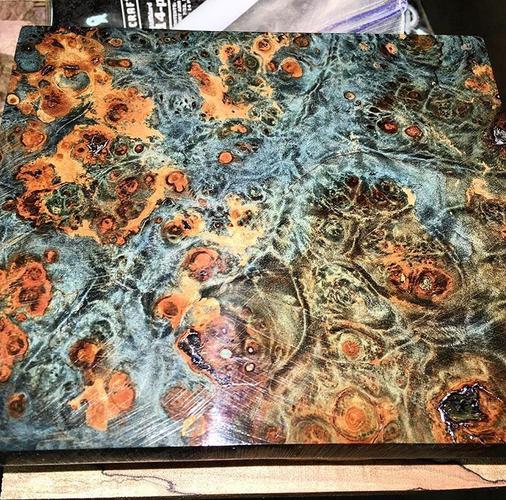

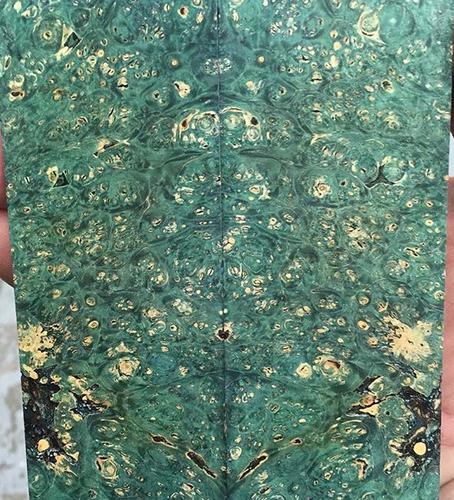

Thanks! I've been making scales for some times and for whatever reason I never used wood up until the last week. I ended up buying about $300 worth of different woods and now I'm playing with it. I cannot believe I did without for so long, now I can hardly get out of the shop... Here a pic of some of the wood

-

The Following 2 Users Say Thank You to Dafonz6987 For This Useful Post:

ob1page (08-05-2016), ScoutHikerDad (08-12-2016)

54Likes

54Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote