Results 1 to 10 of 16

-

11-20-2016, 06:01 AM #1

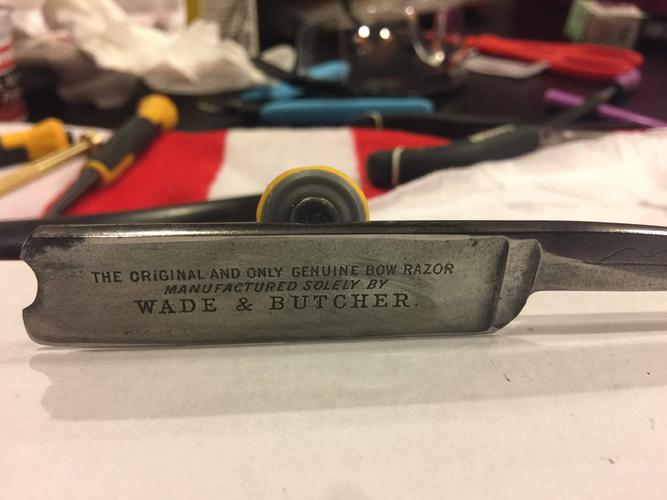

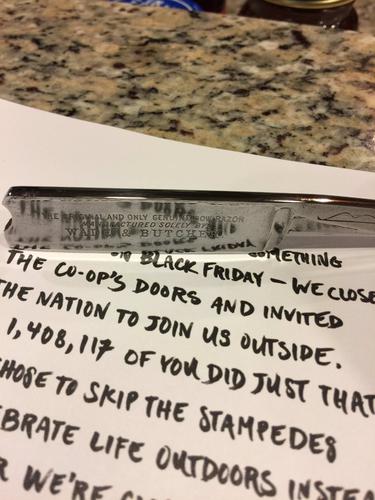

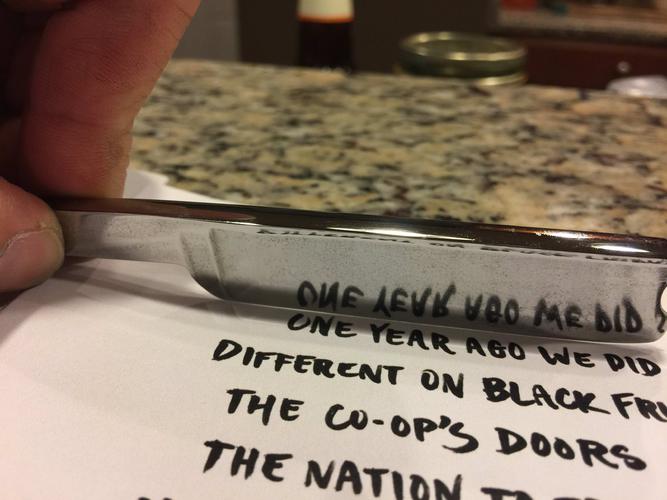

Restoring a W&B - Original Bow Razor

Restoring a W&B - Original Bow Razor

Hey all,

Finally got around to cleaning up and restoring this old beaut!

Pick this up at an Antique store few weeks ago for a steal $20 bucks!

Sent from my iPhone using Tapatalk

-

11-20-2016, 06:30 AM #2Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,450

Thanked: 4829

Looks like it is a good piece to start with. Lots of steel and not a lot of wear.

It's not what you know, it's who you take fishing!

-

11-20-2016, 06:57 AM #3

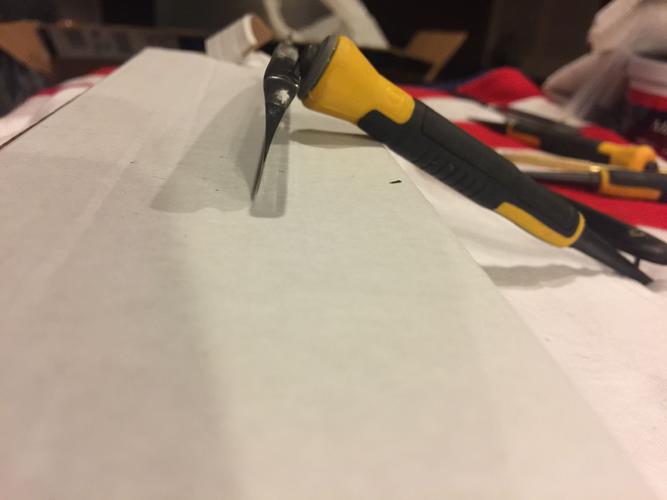

So I started sanding it down and several hours later here is where I am with it. Not too happy with it just yet. You see a lot of pitting that I can probably minimize and the scratches are too visible for my liking.

So far I've hit it with 220, 320, 600, 800, 1500, 2000, red compound, 3 micron lapping paper, 1 micron paper, .3 micron and finally some mothers polish.

I may go back through the grits but doing it for longer. Any suggestion on getting the scratches out? I started with going longways (parallel to the spine) and then started going perpendicular (spine to edge). Should I just stick to one direction? Any suggestions are greatly appreciated!

Sent from my iPhone using Tapatalk

-

11-20-2016, 09:18 AM #4Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,450

Thanked: 4829

What are you using as a backing for the sandpaper? Are you using it wet? WD-40 makes a great wet, that helps to keep the scratches from going too deep. The pitting looks like it is deeper than the etching, so you will be stuck wit some of it. 220 and 320 are too coarse for this kind of work (personal opinion) so I would stick with the 600 until all of the scratches from the lower grits are completely gone. It does get a little hard to tell and in the beginning I went back and forth in grit trying to get the previous scratches removed. If you get bored with the sanding you can chip away at the scales.The backer is important because it keeps the sanding flat and helps preserve the lines of the razor. I use cork others use rubber, leather over wood, hair curlers, the list can go on.

It's not what you know, it's who you take fishing!

-

11-20-2016, 03:59 PM #5

1st, I am NOT a blade restorer, by any means. However, I have refinished several firearms over the years as a gunsmith.

Keep in mind, scratches are nothing more than 'peaks and valley's" in the metal. Working at opposing 45 degree angles to the scratch you want to remove, knocks the "peaks" off.

-

11-20-2016, 04:09 PM #6

Thanks RezDog,

I will go back and spend my Sunday watching the Giants win their acidity game in a row (🤞🏽 and will be going back with some 600 and progressing up from there. Do you tend to stick to just one direction? I am logically conflicted because in my experience in woodworking (building furniture) and with Automotive Detailing, you stick to one direction to avoid cross hatching and swirls.

and will be going back with some 600 and progressing up from there. Do you tend to stick to just one direction? I am logically conflicted because in my experience in woodworking (building furniture) and with Automotive Detailing, you stick to one direction to avoid cross hatching and swirls.

Sent from my iPhone using Tapatalk

-

11-20-2016, 04:18 PM #7

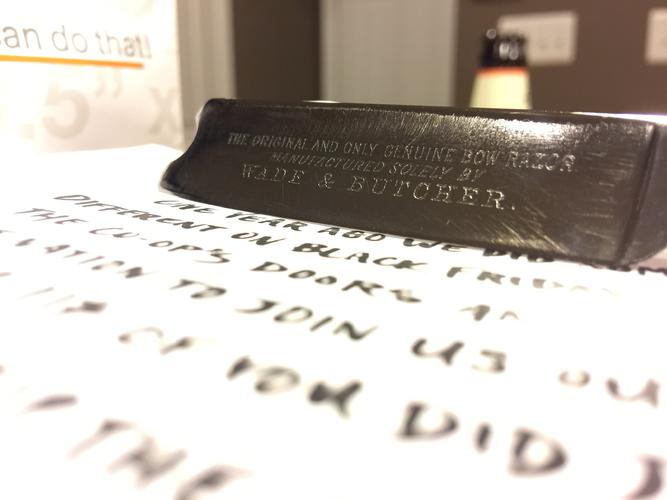

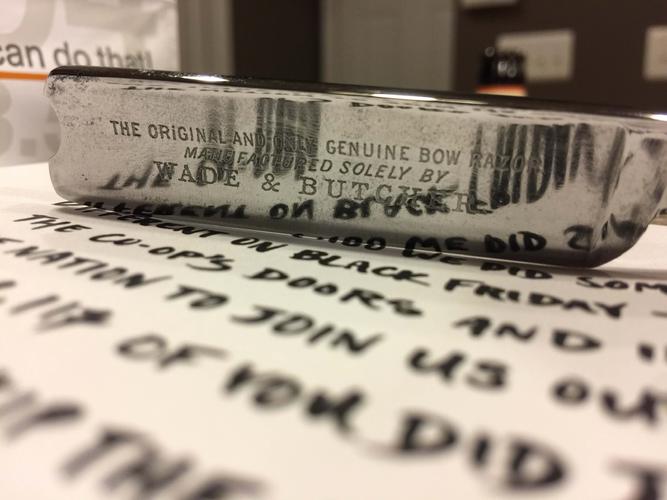

That is a good point AcesandEights! Unfortunately once I got some of the dirt and first layer of tarnish off, I noticed a really deep set of curved scratches. I'll see if I can't find a picture to point them out.

Focus in the area below the "CHER" in Butcher.

In this one you can see the same scratch strokes above the CHER.

Those were there and I tried to get rid of them but they are really deep.

Sent from my iPhone using Tapatalk

-

11-20-2016, 05:32 PM #8

I am doing my first restoration at http://straightrazorpalace.com/works...ing-tools.html so take my recommendations with a grain of salt.

As RezDog said, WD40 + cork works great. In my last session of cleaning I went from higher to lower grits. If I were you, I would start with 1500, see what happens and go lower if needed.

Good luck!

-

11-20-2016, 05:41 PM #9

-

11-20-2016, 05:44 PM #10

I do have a dremel, but I'm honestly more concerned with the level of control and in my opinion, using a Dremel (unless you're a pro) when it comes to detailed task such as this is like using a microwave to make Lasagna instead of using an oven...they may yield Lasagna at the end...but the oven baked one will surely taste better! [emoji51]

Sent from my iPhone using Tapatalk

26Likes

26Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote