Results 11 to 20 of 26

Thread: Dealing with heavy rust?

-

11-26-2016, 12:19 AM #11

Oh, I started the process before reading your message.

Here's what it looks like:

Yep, I read that you can keep on using it until it turns dark.

Hehe, I didn't call anyone but I did google it. What's weird is that amazon returns a product!

2 Pack Elbow Grease~2 each 15 oz:

https://www.amazon.com/Grease-2-Oil-...s=Elbow+Grease

Thanks! I will keep on updating this thread. My main concern is learning and I am happy with the progress

-

11-26-2016, 12:27 AM #12At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,205

- Blog Entries

- 1

Thanked: 13250

Cut a 3x8 piece of 1000 Grit sandpaper or there about

Holding the razor like a knife with the spine OFF the sandpaper set a bevel, look at the bevel with a bright light and magnification... be careful not to flatten out the smile more then it already is (see below)

If you see clean non-pitted steel then continue with the restoration, if not start at square one again

Of course you have already invested time and money in this razor so all that I just typed will be ignored

You also need to recognize that the edge and the Spine "Look" to be out of geometry with each other so honing needs to be targeted on putting it back inline when you hone this

Save Time and Money at the top of this forum

http://straightrazorpalace.com/works...wers-here.html

and in there is exactly what Rezdog/Shaun and I are mentioning about check the steel first

http://straightrazorpalace.com/works...er-2013-a.html

but yes learning and having fun are paramount, being able to actually use it to shave after is pretty fun too

Last edited by gssixgun; 11-26-2016 at 12:31 AM.

-

-

11-26-2016, 12:33 AM #13

-

11-26-2016, 02:13 AM #14

After two hours soaked in EvapoRust:

Will update in two hours.

-

11-26-2016, 04:55 AM #15

-

11-26-2016, 07:52 AM #16

When using EvapoRust, be sure the entire blade is in the solution. If part of the blade is exposed to air you stand a good chance of etching a mark at the air/solution line.

This means you cannot place part of the razor in Evaporust to address a troublesome spot.If you don't care where you are, you are not lost.

-

-

11-26-2016, 06:52 PM #17

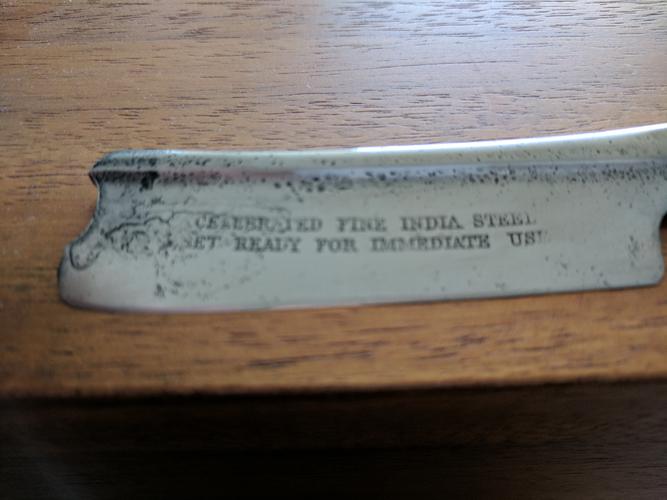

Around 18 hours later:

I have read before starting the process that the metal could get dark. Apparently, 1000 grit should have been able to remove it but since I wanted to work a bit more on the rust close to the blade I went to 400 grit directly.

I don't know why the tang didn't get dark, the entire blade was inside the solution.

"The darkening" disappeared after the first 400 grit pass. This is how it looks after 40 mins of sanding:

A closer look with natural light:

Today I finally saw what some people mention in this thread about rust close to the blade. The magical elbow grease can't save everything? I will put the blade back in the EvapoRust to see what happens...

-

11-26-2016, 08:12 PM #18

IMHO, I would move on to 600, 1000 w/d paper, and polish.

Looking closely at the second to last pic, of the backside of the blade. Those Pitts look pretty deep at the edge near mid blade. There's four in a row, moving from the toe towards mid blade, and a fifth very near the edge, just beyond them.

You may have a small window to obtain a clean bevel between those pits, if not, your gonna be removing some serious steel to get there.

This one had a extremely small window of opportunity, had to keep checking with a loupe to make it.

Mike

Mike

-

-

11-26-2016, 11:27 PM #19

-

11-27-2016, 06:25 PM #20

Update:

I visited Voidmonster and he helped me out setting the bevel. I didn't do a good job taking a picture of the bevel but if you don't believe me, believe Voidmonster

I do a final cleaning today and sand the original scales. Will update soon.

62Likes

62Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote