Results 11 to 20 of 23

Thread: Help getting that mirror finish

-

04-30-2017, 04:07 PM #11

Yep...good ol "blade bling".

Mike

-

04-30-2017, 04:54 PM #12Junior Member

- Join Date

- Mar 2017

- Location

- New Hampshire

- Posts

- 10

Thanked: 0

It depended on the blade. The Wedge I went down to 240 because it was the worst. of the 3, The Magnetic I started @ 400 and the one with the scales still on it honestly I just hit it real quick with 600 then buff wheel and MAAS because the blades in real good condition

the Wedge in question is to the right.

The Magnetic Razor

I don't have original photo's of the one still in scales.

I was wondering if the jump from 600 to 1500 was too much. I do that on the wood turning I do with out an issue but metal obviously is completely different.

I'm also not opposed to devils spit being left as I've read that it may never come out no matter how much sanding you do.Last edited by ssgmeader; 04-30-2017 at 04:59 PM.

-

04-30-2017, 05:19 PM #13Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

["I]I was wondering of the jump from 600 to 1500 was too much. I do that one the wood turning I do with out an issue but metal obviously is completely different."

[/I]

It depends on your 600 finish or even the lower grits. If you have an even finish 600 can easily be removed with 1k or 1.5k. What you see is below the finish. You also have to remove the previous grit scratches with each grit jump. Steel eats paper, much faster than wood. Change your paper often, the backer makes a Big difference, and change directions as I mentioned before.

The pitting I see, in the original photos is the same pitting I see in the finished blade. You did not go deep enough or spend enough time to get an even patter in the low grits.

Your issue is not the finish, it is the base.

I would go back to 400 and try to get an even pattern, keeping an eye on the deepest pits.

I would hit the magnetic with 1k and see, if you have to, drop to 600, 600 scratches come out easy with 1k paper. I often sand a razor with 1k then buff, it will remove a lot of surface imperfections and make a blade pop. 1k scratches can be buffed with metal polish by hand, but a bit of 2k makes it easier, and does not take that much time.

Sometimes, a satin finish is the way to go with problem razors, better yet buy better razors…

It is much easier and safer to sand an unpinned razor

-

04-30-2017, 05:35 PM #14

As you are sanding it is important to use some kind of lubrication, WD40, water, something to help clear the sand paper and clear the scratches you are making with the sand paper as you go. Nothing worse than loading up a piece of sand paper and putting a big gnarly scratch in your piece. I usually fill a Tupperware container ( if my wife is no watching

) or a squirt bottle with water and just a bit of dawn dish soap for my sanding sessions. The dish soap is not a need but I feel it kind of makes things a bit slicker and you also clean as you go

) or a squirt bottle with water and just a bit of dawn dish soap for my sanding sessions. The dish soap is not a need but I feel it kind of makes things a bit slicker and you also clean as you go  Nothing is fool proof, to a sufficiently talented fool...

Nothing is fool proof, to a sufficiently talented fool...

-

04-30-2017, 05:35 PM #15Junior Member

- Join Date

- Mar 2017

- Location

- New Hampshire

- Posts

- 10

Thanked: 0

Any suggestions to make the heel to spine sanding easier. I was doing it and the short strokes are real difficult.

I was thinking a sanding block and strokes light you would hone it. But I doubt thats works on a hollow ground. Is that where the wine cork makes it easier?Last edited by ssgmeader; 04-30-2017 at 05:38 PM.

-

04-30-2017, 05:36 PM #16Junior Member

- Join Date

- Mar 2017

- Location

- New Hampshire

- Posts

- 10

Thanked: 0

-

04-30-2017, 05:42 PM #17

I figured you were but thought just in case id bring it up. I think you are doing fine chasing scratches is never fun, I have done that on paint jobs and that really sucks. Id like to know how the Harbor Freight tumbler goes if you try it.

Nothing is fool proof, to a sufficiently talented fool...

-

04-30-2017, 06:01 PM #18

-

04-30-2017, 06:46 PM #19

I sure hope you are talking about a VIBRATING tumbler.

Ed

-

04-30-2017, 08:26 PM #20Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

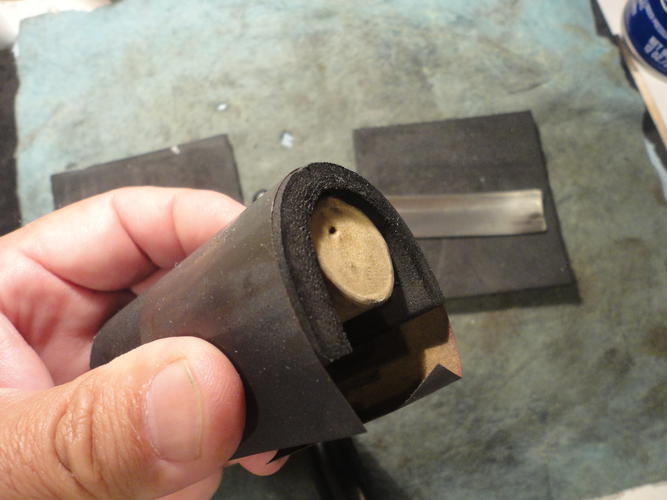

Yup, wine cork, or ½ or ¾ inch PVC pipe coupler. I like synthetic wine corks, the end is flat to get in corners.

Wrap the cork or PVC with a 3x3in piece of craft foam, Wall mart or Craft store or a piece of Yoga mat. Yoga mat makes a great work surface or cushioning for storing stones, and are a buck or two, at thrift stores, cut easily with a razor knife or paper cutter.

Then wrap your 3x3 paper around the cork and foam. You can use the whole piece of paper, by flipping it around, the thickness, is also easier on your hands and can be adjusted for the hollow grind, with the cork and pipe couplings.

-

The Following 3 Users Say Thank You to Euclid440 For This Useful Post:

lloydw (05-01-2017), MisterClean (05-02-2017), Mrchick (04-30-2017)

49Likes

49Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote