Results 1 to 10 of 29

Thread: Inlays in horn

Hybrid View

-

08-04-2018, 02:17 AM #1

Not really inlays, are they?

A long-ago member replicated those scales and deemed them junk. Did an awesome job!

I begged for them on customs and restos.

He sent them to me from Europe!

-

08-04-2018, 03:05 AM #2

Junk??? Hmmm that's a dubious appraisal. I think they look great, there may be trade-offs with any design depending on the value given to any one aspect.

On that one I notice that the two scales "might" have different flex strengths due to the oversized pin inlays only on one side, which could lead to one scale finding a different flex resting place..

Perhaps put them on the other side too?

No need probably.. it's an awesome design in my book.“You must unlearn what you have learned.”

– Yoda

-

08-04-2018, 03:35 AM #3

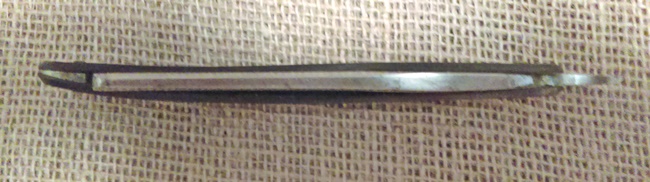

Lots of bug damage and de-lamination on them. CA and dyed epoxy got them going again.

One of those 'Butchered Blades' razors!

-

08-04-2018, 03:17 PM #4

Good questions!

These pewter inlays are combination of pins rivited on the backside and pressing into the recess. They seem to have undercut the openings so the pieces are firmly controlled for the last century.

And, yes the shrinkage is different between the scales:

YMMV

Have fun!

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

The Following User Says Thank You to Geezer For This Useful Post:

MikeT (08-04-2018)

-

08-04-2018, 06:56 PM #5

Excellent! Thank you again Richard.

Though it presents the need for more work, I tend to like symmetry.. so an equal inlay on each side..?

Does anyone have the temperature that horn becomes plasticized? And then what range do we have to work with before it is too soft and/or begins to burn or bubble?

Not that it would be necessary.. but a laser temp reader might be handy in that regard.“You must unlearn what you have learned.”

– Yoda

80Likes

80Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote