Results 1 to 8 of 8

32Likes

32Likes

Thread: How I made (PETE) Clear Plastic Thrust Washers

Threaded View

-

03-18-2019, 04:10 AM #1Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215 How I made (PETE) Clear Plastic Thrust Washers

How I made (PETE) Clear Plastic Thrust Washers

(PETE) Clear Plastic Thrust Washers

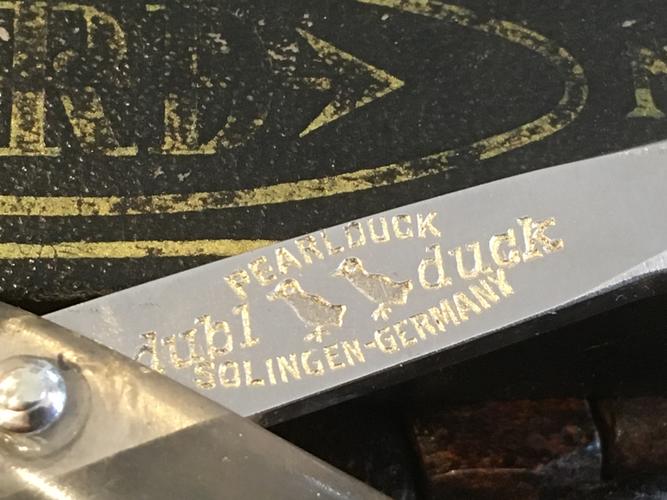

I recently posted a thread about a very nice Satin Wedge Double Duck I pick up for a song, with no Cell Rot and almost no hone wear.

Original scales with brass thrust washers.

One of the things I don’t like about Ducks with transparent scales is the brass thrust washers at the pivot. They look ok new, but once they start to tarnish the pivot looks dirty. So, I made new clear plastic thrust washers from a(PETE), plastic water bottle with a leather hand punch.

Some failed attempts at centering the hole. Note washer compared to originals.

They came out fine, just a bit smaller than stock and about as thin and are almost invisible. The pivot action is nice and smooth. I also domed collars just a bit larger, to hide the indents and slight cracking where the old collars bit into the brittle celluloid.

I used a rotary leather punch at the largest die, just under a ¼ inch. The problem I had was, centering the hole as the scales were clear and anything but centered would show.

First, I punched out a dozen discs. I put 2 layers of electrical tape on the brass anvil and punch a hole in the tape and removed the “hole” leaving the surrounding tape.

Electrical Tape centering hole.

Place a disc in the hole in the tape. The little bit of tape on the perimeter of the punched hole, helps hold the disc in place. Now at the smallest punch setting about a 1/6th in. center and punch the center hole. All the dies use the same center point.

You may have to adjust as these are not high-quality punches, but you can adjust by eye a bit. I cranked out a dozen in 5 minutes. And plan on using them with translucent and light-colored scales in place of brass.

Pinned and finished, note how invisible the PETE plastic washer are.

-

The Following 13 Users Say Thank You to Euclid440 For This Useful Post:

BobH (03-18-2019), Diboll (03-18-2019), Geezer (03-18-2019), JellyJar (03-19-2019), JP5 (03-19-2019), JSmith1983 (03-19-2019), markbignosekelly (03-18-2019), Montgomery (09-21-2019), outback (03-19-2019), randydance062449 (03-18-2019), spazola (03-18-2019), Theoman (03-18-2019), tintin (03-18-2019)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote