Results 11 to 20 of 39

-

01-12-2023, 01:03 AM #11Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

.

.

Carbon black can be found at Art Supply houses as a pigment and graphite is purchased in a little tube which is to be used as a lock lubricant.Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

01-12-2023, 03:04 AM #12

Last edited by outback; 01-12-2023 at 04:51 AM.

Mike

-

-

01-12-2023, 10:50 PM #13

I also use charcoal powder plus some dark brown sawdust to give that slight hint of brown to the epoxy. Some horn more than others is lighter in color and the jet black shows in a patch.

https://sharprazorpalace.com/worksho...ml#post1939944Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

The Following User Says Thank You to PaulFLUS For This Useful Post:

DZEC (01-16-2023)

-

01-12-2023, 11:10 PM #14

Unless you live in Arizona or similar arid climates use WD-40 instead. Locks don't really need much lubrication and work fine dry as long as they are free from corrosion. WD-40 is one of the best anticorrosive agents you can get and it is not oily. Oil is your other enemy with locks because the springs inside are so small(the wire is about the diameter of a beard hair) that the viscosity of the oil renders them inoperable causing the tumblers to stick.

On the left is a typical auto lock cylinder spring and on the right is a typical residential/commercial lock cylinder sprng.

In climates where there is any appreciable amount of humidity graphite will turn to gum inside the lock and if there is any oily residue it will turn into sticky gum actually making it work worse than it would clean and dry. In addition to that, more than a puff of graphite can be compressed by the insertion of the key and turned into a rock. I have pulled key shaped rocks out of locks where.the owner figured that if a little is good a lot must be great.

The one downside to using WD-40 is that it dissipates quicker than oil. Although this is actually a good thing it necessitates more frequent use. As a rule of thumb once per quarter/season is best.

I'm done...

Carry on...Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

The Following 3 Users Say Thank You to PaulFLUS For This Useful Post:

DZEC (01-13-2023), randydance062449 (01-16-2023), tintin (01-13-2023)

-

01-16-2023, 12:18 AM #15Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,807

Thanked: 559

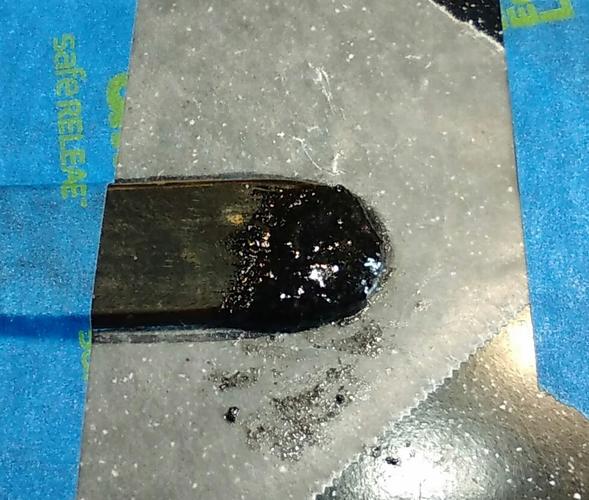

Well I got to where my tools are and managed to separate the scales from the blade. You’ll see in the next post that was not entirely successful.

I used the 3M Marine and some 1200 wet/dry to remove most of the black stuff. The blade seems to be in excellent shape with the exception of some microchips that I’ll have to hone out later.

David

David

“Shared sorrow is lessened, shared joy is increased”

― Spider Robinson, Callahan's Crosstime Saloon

-

01-16-2023, 12:24 AM #16Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,807

Thanked: 559 Not so much luck with the scales

Not so much luck with the scales

When I tried to remove the scales, the pins were really stuck in the holes. I guess the horn had shrunk over the years. So I decided to cut them off with my side cutters.

When I tried to separate the scales, I used a flat blade screwdriver to act as a wedge and tried to ease the scales apart. That didn’t work and I wound up cracking one scale and leaving bits of the pin in each. I can drill that out later.

I am really intimidated by these old horn scales and would appreciate some advice about what to do next.

David

David

“Shared sorrow is lessened, shared joy is increased”

― Spider Robinson, Callahan's Crosstime Saloon

-

01-16-2023, 03:00 AM #17

Short, quick story...

1st, CA and clamp the crack.

Sand scales with 220 sandpaper, removing the old, dried horn from the scales.

Make epoxy repairs, sand repairs to match the contours of the scales. Then smooth with 400, 600, 0000steel wool.

Wipe with denatured alcohol, then you can dye if desired, then soak in neats foot oil.Mike

-

The Following 2 Users Say Thank You to outback For This Useful Post:

DZEC (01-16-2023), randydance062449 (01-16-2023)

-

01-16-2023, 02:26 PM #18

Tape the outside of the scales with scotch tape, over the repair areas. Fill with epoxy from the inside side of the scales. The tape acts as a molding to create the shape of the existing scale.

Last edited by outback; 01-16-2023 at 02:30 PM.

Mike

-

The Following 2 Users Say Thank You to outback For This Useful Post:

DZEC (01-16-2023), randydance062449 (01-16-2023)

-

01-16-2023, 03:34 PM #19

-

01-16-2023, 10:34 PM #20Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,807

Thanked: 559

100Likes

100Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote