Results 1 to 10 of 14

Thread: pasting with powders

-

07-24-2009, 01:44 AM #1

pasting with powders

pasting with powders

I was not sure where to put this thread - I decided to put it in the workshop because it is kind of about building stuff.

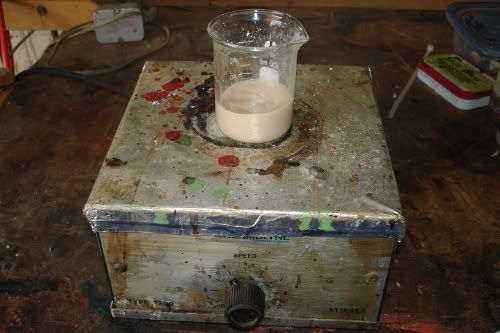

Here is how I have been applying powder abrasive lately. I have been using a little bit of wax as a binder to keep the abrasives where I put them. Here are some pics showing how I applied cerium oxide to a couple of bench strops, One is balsa the other is denim covered.

I mix a pea size ball of wax in about an ounce of solvent (naptha, mineral spirits, lighter fluid, - anything wax is soluble in), When the wax is dissolved I add about a 1/2 teaspoon of abrasive and mix well. I used an atomizer this time too apply the mixture but a rag works nearly as well.

I have also used this technique with bars of buffing compound, I substitute the wax and abrasive with a small chunk of the buffing compound bar. Wax based buffing compounds dissolves pretty easily.

It is a little more involved than just rubbing the dry powder into the cloth or the wood, but it works very well and keeps the powder from getting everywhere. I like the way the bees wax makes the balsa feel.

Charlie

Last edited by spazola; 07-24-2009 at 07:14 PM.

-

The Following User Says Thank You to spazola For This Useful Post:

T-Ram (07-27-2009)

-

07-25-2009, 03:13 AM #2Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

Thanks for the post!

I think your on to something. I have been using some very old neatsfoot oil that seperates if left alone for some time. One part is oil and the other is a thick, fat like substance.

When I heat it up it dissolves into a homogenous fluid. Then when mixed with an abrasive and applied to a paddle strop it hardens a bit and holds the abrasive in place very nicely.

It works just fine.

I have noticed that both the red and black abrasive pastes from Dovo are not dry powder or oily but rather a thick paste, maybe it hardens like a wax?Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

The Following User Says Thank You to randydance062449 For This Useful Post:

spazola (07-25-2009)

-

07-25-2009, 04:59 PM #3

Now we have 2 MacGyver's

Great groundwork Charlie and Randy. Gotta give it a try.

əˌfisyəˈnädō | pərˈfekSH(ə)nəst | eS'prəSSo | düvəl ləvər

-

The Following User Says Thank You to Maximilian For This Useful Post:

spazola (07-27-2009)

-

07-25-2009, 05:00 PM #4I shave with a spoon on a stick.

- Join Date

- Jan 2009

- Location

- Stay away stalker!

- Posts

- 4,578

- Blog Entries

- 1

Thanked: 1262

Thanks. I have been tyring to figure out the best way to apply my CrO and CeRo powders to felt.

-

The Following User Says Thank You to Slartibartfast For This Useful Post:

spazola (07-27-2009)

-

07-27-2009, 07:39 AM #5Senior Member

- Join Date

- Mar 2007

- Posts

- 608

Thanked: 124

I've mixed CrO with water and detergent to apply it, it seems to work ok. The Cro seemed to give pretty good results when you put it in a spray bottle liquefied like that. You can make a solution with just a little CrO and don't have to worry about over applying it.

Used detergent b/c thats what handamerican mixed with their liquid CrO, I don't know if it really does anything or not, but the CrO and the cerium seem to stick pretty well when applied with it.

-

The Following User Says Thank You to Pete_S For This Useful Post:

spazola (07-27-2009)

-

07-27-2009, 11:07 AM #6Stubble Slayer

- Join Date

- Jan 2009

- Location

- Alexandria, VA

- Posts

- 708

Thanked: 171

FWIW I applied both my CrOx and cerium oxide with mineral oil. Just dip the tip of my finger in mineral oil, then touch the powder to pick some up, smear it on, and repeat. Both have stayed applied nice and even and work well. I can't remember who's idea it originally is, but not mine. I think I read it in the wiki.

Your process might even be better, but for now I'm not noticing any problems with the mineral oil, at least applied to balsa wood paddle strops. The strops aren't oily in any way shape or form -- you just don't use enough oil for this to be the case. This method may not work so hot for linen/cotton/felt based strops, though.

-

The Following User Says Thank You to pjrage For This Useful Post:

spazola (07-27-2009)

-

07-27-2009, 02:12 PM #7Senior Member

- Join Date

- Dec 2008

- Location

- Long Branch, NJ

- Posts

- 152

Thanked: 18

I may have applied my crom ox on balsa all wrong from what im reading here. I made a nice balsa paddle and applied the crom with norton honing oil. It went on just like paint. I have been using it everytime i hone with good results but would it be better using another metho? help anyone.

-

The Following User Says Thank You to importcarguy For This Useful Post:

spazola (07-27-2009)

-

07-27-2009, 02:52 PM #8Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

-

The Following User Says Thank You to randydance062449 For This Useful Post:

spazola (07-27-2009)

-

07-27-2009, 05:54 PM #9

I posted this to show people what I have been doing. It is not THE way to do it, it is just another arrow in your quiver.

My favorite pasted strop is a linen strop with dry powder (cro2 and 1.8 boron carbide) rubbed into to it.

I like to try different things and experiment. I have read on this forum before about chrome ox being messy. This would be one method that could be used to keep it tidy.

Charlie

-

07-27-2009, 06:30 PM #10At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,194

- Blog Entries

- 1

Thanked: 13250

Hi my name is Glen and I am a complete moron, but is that candle wax??????????

-

The Following User Says Thank You to gssixgun For This Useful Post:

spazola (07-28-2009)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote