Results 11 to 20 of 24

-

08-20-2010, 12:38 AM #11At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,046

- Blog Entries

- 1

Thanked: 13249

TY Neil I will look really close with a loupe when I get home again at the WG/C and see...

-

08-20-2010, 02:33 AM #12

Glen, unfortunately, I can say nothing about this razors maker.

I know Thomas Wilton, but not W.G.

But I'll try to find some info.Alex Ts.

-

The Following User Says Thank You to manah For This Useful Post:

gssixgun (08-20-2010)

-

08-20-2010, 03:14 PM #13

If I look at the razor mark I´m shure it´s the same like this: Fine Razors - W.C. Wilton 9/8 with bone

But now I´m not longer shure, if the G or the C is right

-

08-20-2010, 04:01 PM #14At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,046

- Blog Entries

- 1

Thanked: 13249

Looks to be the same...

TY Buddel

I am thinking more G. than C. who knows though, even in the books I have seen some of those initials wrong... But at least we all agree on W. Wilton

-

08-20-2010, 04:49 PM #15

What are you going to do for a sharpness test when you're done? Butcher up some pork chops for the BBQ? Don't drop that sucker!

-

08-28-2010, 05:58 PM #16At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,046

- Blog Entries

- 1

Thanked: 13249 Update !!!

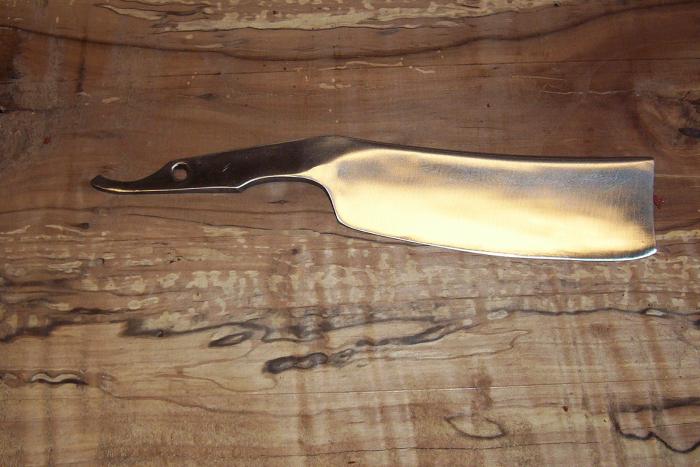

Update !!!

Some updated work pics

This one did not go quite as planned, after 4 passes at the buffers the pitting was still in there so I decided to take it to the next level and re-grind the faces.. These pics are at 80 grit on the buffers with greaseless compound...

I will set a bevel on the razor tonight to make sure it is all even, then re-buff the razor to as close to mirror as I can get... Then after all that fun I'll re-set a bevel and hone her up...

Now the scales are coming along too...

This is highly figured Leopardwood I picked re-con Amber for the wedge..

I am putting on layers of CA right now for the finish, but I haven't decided where I am going yet with the Hardware and 3rd pin....

-

08-29-2010, 01:13 AM #17

Looks great so far! Did you do the regrind using 80 grit greaseless or was it with a grinder?

-

08-29-2010, 02:16 AM #18At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,046

- Blog Entries

- 1

Thanked: 13249

It was not with the Greaseless, but what I did is not a safe nor smart operation so I will leave the details out...

It was not with the Greaseless, but what I did is not a safe nor smart operation so I will leave the details out...

With a razor like this that is so thick and has so much steel you can get away with much, much more...

-

08-29-2010, 06:32 AM #19

-

08-29-2010, 07:42 AM #20

beautiful razor/beautiful wood.

Please share with us the result of your work.

Regards

Tom

2Likes

2Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote