Results 1 to 10 of 17

Thread: where can I get these pins?

-

10-07-2010, 12:11 PM #1Junior Member

- Join Date

- Jun 2009

- Posts

- 9

Thanked: 1 where can I get these pins?

where can I get these pins?

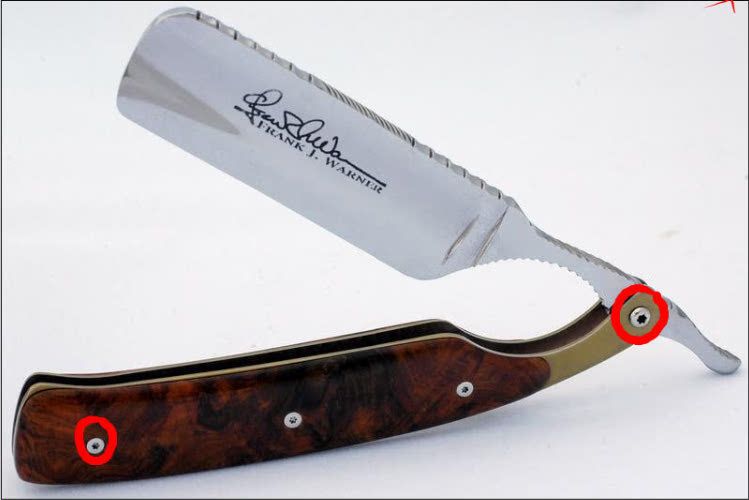

where can I aquire these "hex" head pins and what size for my razor projects? Is there a female end that they screw into? Ive searched and searched but to no avail.

Thank you to whoever supplied this picture for me !

-

10-07-2010, 12:49 PM #2

here you get all items you need

-

The Following User Says Thank You to eTom For This Useful Post:

CheshireCat (05-23-2013)

-

10-07-2010, 01:21 PM #3

Here is one place, look at knife making supply places. They will have them under their folding knife stuff.

Pivot Barrel 1/8 for folders Knife folder Pivots 1/8 3/16 1/4 Barrel

Charlie

-

The Following 2 Users Say Thank You to spazola For This Useful Post:

CheshireCat (05-23-2013), jpm7676 (10-07-2010)

-

10-07-2010, 02:11 PM #4Senior Member

- Join Date

- Jan 2008

- Posts

- 701

Thanked: 182

thats the place i get mine

and they use 2-56 screws

you can also get smaller screws but 1/8 inch is the smallest pivot setup i have seen

-

10-07-2010, 02:11 PM #5

Charlie's link is where I get mine. Be advised that you will need to drill a 1/8" hole for the pivot to fit the 1/8" pivot barrel which you will also need to cut to width and make sure it's flush with both sides of the tang. If not you'll have to find washers with a wide enough diameter to fit the barrel if it's sticking out. Be very carful when trying to drill a 1/8" hole in your pivot. make sure the razor is clamped thigh and secure.

əˌfisyəˈnädō | pərˈfekSH(ə)nəst | eS'prəSSo | düvəl ləvər

-

The Following User Says Thank You to Maximilian For This Useful Post:

eTom (10-07-2010)

-

10-07-2010, 02:14 PM #6Senior Member

- Join Date

- Jan 2008

- Posts

- 701

Thanked: 182

yep 1/8 inch hole

but i also do the scales in 1/8 hole also and let the pivot go through the whole works (must not have the puvot flush with the handle tho as then you cant tighten the pivot up at all )

-

The Following 2 Users Say Thank You to L R Harner For This Useful Post:

CheshireCat (05-23-2013), Maximilian (10-07-2010)

-

10-07-2010, 02:19 PM #7Junior Member

- Join Date

- Jun 2009

- Posts

- 9

Thanked: 1

would it be wize to grind the barrel down with a grinder to make it flush with the tang?

-

10-07-2010, 02:21 PM #8Junior Member

- Join Date

- Jun 2009

- Posts

- 9

Thanked: 1

so rather than grind the barrel to the tang I should make it even with the face of my scales?

-

10-07-2010, 02:27 PM #9

There's 2 ways to use the barrel. Llike I explained or like Butch does partly because he's a custom maker and it's easier to put everything together when you do it all from blade to scales. A brand new custom made straight razor is usually straight. Most vintage razors can have some tang issues. In that case if you go straight to the outside of the scales you will encounter problems centering the blade as there is no play. I have found it easier to do it my way on most vintage straight razors. Both ways work, you just have to find what works best for you.

I usually saw it in 2 with my dremel (metal cutting wheel) as I can use 1 barrel twice. I use my belt sander to sand/cut to width. The grinder could work but I'll make sure not to use the fastest speed and also clamp that barrel onto something so you don't end cursing trying to find it while crawling around on your hand and knees.Last edited by Maximilian; 10-07-2010 at 02:33 PM.

əˌfisyəˈnädō | pərˈfekSH(ə)nəst | eS'prəSSo | düvəl ləvər

-

10-07-2010, 02:39 PM #10Junior Member

- Join Date

- Jun 2009

- Posts

- 9

Thanked: 1

Gotcha, Thanks to all for the help, im glad to be a part of this forum thats willing to help a beginner like myself. Ill post a pic of it when ive completed it.

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote