Results 1 to 6 of 6

11Likes

11Likes

Thread: Magnetic Razor Jig

Hybrid View

-

06-27-2011, 12:35 AM #1Senior Member

- Join Date

- Mar 2011

- Location

- Washington DC Metro Area

- Posts

- 468

Thanked: 114 Magnetic Razor Jig

Magnetic Razor Jig

I made a magnetic razor jig following the instructions at:

http://razortips.blogspot.com/2009/02/making-blade-safety-jig.html

Once made, the jig works great. Great design, Bill. It holds razors very securely Ė so securely that I let my daughter help with some light polishing work.

However, making the jig can be dangerous. Donít do what I did. I used a belt sander to trim the sheet metal and wood and the magnets had a tendency to grab the sander when youíre not expecting. I once had a block of wood with sharp sheet metal attached fly across the room! The magnets are strong! Be careful everyone.

-

-

11-15-2012, 10:42 AM #2

This jig is amazing. Thank you so much for sharing. A magnetic razor jig is a must for restorations in my opinion. My first restoration effort I did without one. I figured, how hard can it be? It is hard. If you don't cut yourself, the odds of dropping the blade are excellent (I did and broke the tip). Especially if you spray WD40 on it while you are sanding. It takes ten minutes to make a and saves hours in more efficient sanding and buffing, and it dramatically reduces the risk of personal injury. I just took a piece of board, drilled a few holes and put magnets in. You can get rare earth magnets from a wood working store like Woodcraft. If you some dead hard drives in a closet you can break those apart and use the magnets. Google how to do that. Getting the magnets free was not completely trivial. For my jig I used double layers of hard drive magnets. I didn't bother putting a guide on top as they do in the link. The grip from the magnets is hard and the blade doesn't slide around anyway. Rather than making a metal plate to cover (I didn't have any, and it seemed over-engineered) I stretched a piece of leather across and stapled it along the edges. Final trick, the leather does trap some metal filings. When I go from sanding to buffing, I put a piece of stiff plastic on, from a sheet protector. That stops any metal grounds from messing up the buffing wheel and scratch things up.

-

11-15-2012, 05:19 PM #3

Here's a razor jig I made some 3 years ago using not only the rare earth magnets found in an old harddrive, but the outer case of the drive itself. It works really well and was pretty straightforward to make...

http://straightrazorpalace.com/works...blade-jig.html

Cheers,

- Mike

-

11-16-2012, 04:42 PM #4

It was mentioned above but I will emphasis it

Use a masking tape or #33 electrical tape over the magnets. That will prevent the magnets from polishing a spot on the blade where they contact it. Change the tape when turning the blade over.

I learned that the hard way!

~Richard

I have the Gentleman's Best model of wood with the magnets exposed and an aluminum sheet inset at the blade edge.

-

11-17-2012, 03:59 PM #5

Lazy man's finger and blade saving magnetic jig

Lazy man's finger and blade saving magnetic jig

Here is my bare bones finger saving jig, obviously inspired by the nice work of others. I only had about a dozen razor to fix so I didn't want spend too much time on making a jig. Two hard drives' worth of magnets and a couple of other rare earth magnets I had left from something else. Hard drive magnets are pretty large and oddly shaped. All magnets are double. Drilled a few big holes in a piece of board. Spackled all the extra space in a couple of rounds, and sanded all flat.

In the jig's first edition I stretched and stapled a piece of deer hide over it. You can still see the holes from the staples. It looked great for the first five blades but got pretty ugly and black after.

In jig rev. 2 I simply took a part of a CD-case. I haven't even fastened it to the board. It doesn't matter that it is loose. The magnets are so strong everything is held firmly in place while it is in use. For polishing I put a piece of stiff plastic cut from a sheet protector. Works great. I see no need for the guide that I have seen on other variations of magnetic jigs. The magnets, at least when doubled up, are very strong! This jig took marginally longer to make than it took to write this and take the pictures.

Besides the superbly easy way to fix the blades while sanding, jigs offer another advantage: The odds of breaking old and brittle scales are dramatically reduced!

Last edited by Storsven; 11-17-2012 at 04:05 PM. Reason: Extra clarification

-

The Following User Says Thank You to Storsven For This Useful Post:

Geezer (11-17-2012)

-

11-18-2012, 05:46 PM #6Senior Member

- Join Date

- Dec 2011

- Location

- I'm Gonna Spend Another Fall In Philadelphia

- Posts

- 2,024

Thanked: 498

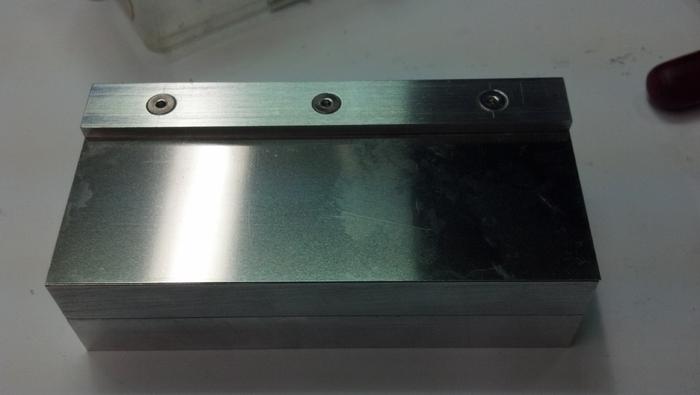

That instruction was a godsend to me. I followed the instructions pretty much to a tee, but I used aluminum body components instead of wood.

I super glued the thin stainless steel shim stock to the top surface and fastened it all together with stainless steel screws.

It works like a champ. Almost to good, those rare earth magnets are down right dangerous.

-

The Following User Says Thank You to Tarkus For This Useful Post:

Geezer (11-19-2012)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote