Results 1 to 10 of 15

Thread: Making a paddle strop- Tutorial

-

10-10-2011, 12:04 AM #1I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591 Making a paddle strop- Tutorial

Making a paddle strop- Tutorial

I have been planing to make a new paddle strop for a while now, and today I finally decided to do it. In the process I thought I'd take a few pics and post here for others to try if they want.

This is not my first paddle strop. I made a similar one before, for it I used Latigo and felt to make it double sided paddle.

For both strops I used Iwasaki's method of treating the leather to make it as smooth as possible.

I wanted to make the new strop with horse hide, recently I got a nice big piece of 7oz horsehide from e-bay. I used one of the pieces from it for the paddle today.

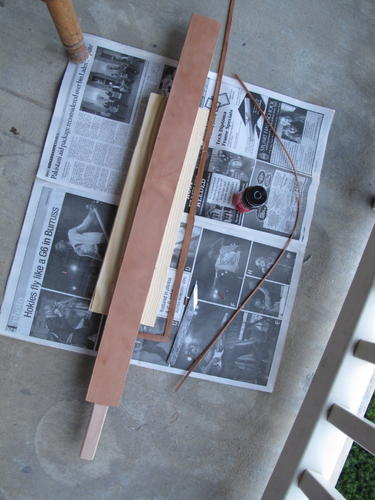

First I got a 3" wide piece of oak from Home depot and cut it to 3 feet length. Please be sure when you buy wood for paddle , that it is flat, wood with bow will not be very useful IMO.

I cut a handle in the paddle and sanded lightly the surface that will meet the leather with a medium sandpaper sponge. After that I applied contact cement to both the leather(on the rough side) and the paddle:

The leather was wider and longer than the paddle , so I trimmed it to match.

The leather is untreated so it is not even, to correct this I use sandpaper progression.

First I scuffed the strop with 400 sandpaper to show how many low spots it has:

To speed up the work on flattening the leather I use 150 grit sandpaper first. I use a wood block to wrap the sand paper around to make sure it is flat when sanding the surface of the strop.

Last edited by mainaman; 10-10-2011 at 12:19 AM.

Stefan

-

10-10-2011, 12:13 AM #2I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

After the 150 sand paper I continued with 220, 400, 600

After 600 I go to 800, 1000, 2000 grit.

Here I use a wet towel on the leather prior to using the sand paper. This allows for less loading of the sand paper. I should have done this starting from 400 grit , but it worked fine this way too.

800 grit

1000 grit

2000 grit

As you can see this becomes very highly polished leather surface:

From the pics it is obvious there is a low spot left that I have to get rid of , but it will not affect the stropping. I have to redo the finish to get the surface smoother, but even like that it will work fine, I just am a bit OCD so I'll redo it soon.

Maintenance of the paddle.

After some use there will be metal particles left on the surface of the strop

The maintenance is very simple just go back to 1k and 2k sand paper and recondition the surface.

Here are my two paddle strops:

Those smoothed surfaces produce great edge on a razor, they work extremely well on Kamisori in my experience.

Hope this is helpful for those that want to make their own paddle strop.Last edited by mainaman; 10-10-2011 at 12:18 AM.

Stefan

-

The Following 12 Users Say Thank You to mainaman For This Useful Post:

-

10-10-2011, 06:31 AM #350 year str. shaver

- Join Date

- Aug 2008

- Location

- Pothole County, PA

- Posts

- 2,258

- Blog Entries

- 2

Thanked: 522

Stefan

That's a very nice effort on your paddle strops. You must have very long arms. I prefer a shorter strop length.

Thanks for sharing your good work.

Nice toenails too!

Jerry

____JERRY

OOOPS! Pass the styptic please.

-

10-10-2011, 08:13 AM #4Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

Looks like some very nice work.

Did you find that the sandpaper left any embedded grit in the leather? If so, how did you get it out?Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

10-10-2011, 10:17 AM #5I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

-

10-10-2011, 10:17 AM #6I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

-

The Following User Says Thank You to mainaman For This Useful Post:

skipnord (10-10-2011)

-

10-14-2011, 08:13 PM #7Senior Member

- Join Date

- Mar 2011

- Location

- Washington DC Metro Area

- Posts

- 468

Thanked: 114

Thanks for sharing this. I've sanded out leather nicks with 400 grit before, but it never occured to me that leather could be polished up so nicely by apply further grits. This post has inspired me to go back and redo some old repaired strops and possibly polish a few to experiment with draw characteristics. Thanks again.

-

10-16-2011, 03:10 PM #8Senior Member

- Join Date

- Mar 2011

- Location

- Washington DC Metro Area

- Posts

- 468

Thanked: 114

My 9 year old daughter asked me again this morning if we can “do razors” – I’m very lucky that she likes to tinker with Dad in the garage. So I let her remove a few light nicks in my SRD Premium 1. She started with 400 grit sandpaper to remove the nicks and then progressed through the grits all the way through 2000. Then she used the micromesh and worked all the way through 12000. To blend everything smooth, I let her condition the entire strop with the micromesh, not just the repaired areas. The result is a functionally brand new strop! Thanks for the inspiration Mainaman (and thanks for the fun project idea for my daughter – she had a blast).

-

10-16-2011, 03:12 PM #9I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

-

10-16-2011, 03:32 PM #10

Nice Job Stefan, Kind of short though...Ha....!

We have assumed control !

11Likes

11Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote