Results 1 to 10 of 14

-

04-24-2012, 02:32 AM #1

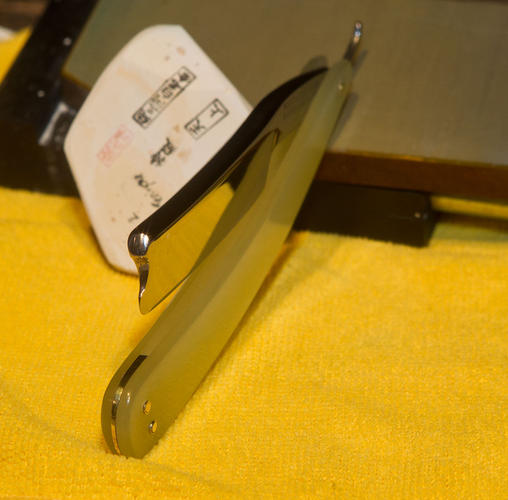

First Restore - I'm not done yet!

First Restore - I'm not done yet!

This is my first attempt at a restore and I have learned much - but have a lot to learn. I suppose it's a good idea to see how an auction blade hones before going to all the trouble to restore and make scales.

I really wanted to try my hand at scales and had fun, so no regrets, but my last step was to (try to) hone this beast. I used 3 layers of tape and went through the progression thinking I had a good edge. My first shave this morning resulted in a really nice shave - except for the tip of the blade. The last 1/2" of the blade is not sharp.

I noticed that the nose does not make full contact on one side, but thought I had this corrected using a rolling x stroke. Apparently not - or maybe not yet. I'm not opposed to sending it out, but would like to learn, or at least know how to handle this situation.

-

04-24-2012, 03:18 PM #2

Looks great.

I just did my first as well and as I have not learned honing "yet" I have no idea if it will hone properly but I will soon find out. For me it was still worth the learning experience ether way it turns out. Though I did not have to make any scales for mine. I had fun and learned a lot as I'm sure you did as well.

-

The Following User Says Thank You to Mick For This Useful Post:

DBurnette (04-25-2012)

-

04-24-2012, 03:20 PM #3

What a lovely job!!!

You certainly jumped in at the deep end for your first - and swam well, by the looks.

It is a beautiful blade too.

I wish it were mine - well done

-

The Following User Says Thank You to Havachat45 For This Useful Post:

DBurnette (04-25-2012)

-

04-24-2012, 09:10 PM #4

I suppose if I want answers, I need to ask questions, which I did a very poor job of. Let me start over without starting a new thread:

I posted this thread some time back concerning the above blade:

http://straightrazorpalace.com/works...ht=#post950453

I thought there was the slightest amount of frown in the blade, so I slightly reshaped the middle to toe on a Tormek wet wheel. I held the blade at a 45 degree angle to the wheel and removed the frown. My instinct is that this did not effect the spine, so I don't know that this procedure would result in not being able to hone the toe, but I throw that out, for what it's worth.

My first attempt at setting the bevel was done with 2 layers of 3M. I noticed some light scratches on the blade above the bevel on the toe, so thinking I needed a little steeper angle, I went to 3 layers and completed the bevel ( I thought).

What I am asking is whether I should:

1. re-work the entire blade, starting with 1000K bevel set?

2. go back to work just the toe area in question? Add more tape?

3. send it out to one of the pros and miss the satisfaction and gratification of competing the project?

4. melt the sucker down and make a bracelet?

5. other?

Thanks for your collective help.Last edited by DBurnette; 04-24-2012 at 09:12 PM. Reason: correction

-

04-24-2012, 10:44 PM #5Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

If the bevel is set correctly it should shave arm hair easilly along" the entire edge of the blade", if that the case or not i would use a marker on the edge and find a stroke that covers the entire edge. But dont let me see a thread called Wade and Butcher bracelet.

-

The Following User Says Thank You to Martin103 For This Useful Post:

DBurnette (04-25-2012)

-

04-24-2012, 11:03 PM #6

That wedge with those scales just pulls everything together. Is it a lead wedge? Those little subtle details just makes a razor look alot better "Thats my OCD talking". Very nice! That is my opinion though.

Last edited by JSmith1983; 04-24-2012 at 11:06 PM.

-

The Following User Says Thank You to JSmith1983 For This Useful Post:

DBurnette (04-25-2012)

-

04-24-2012, 11:30 PM #7

If someone had given me a razor that had been worked freehand on a grinder as you've just done, I'd go back to setting a bevel and I'd stay on the 1K stone with a magic marker test until it shaved arm hair all along the blade, before moving to a higher grit -- no matter how long it took.

I'd also suggest to this hypothetical fellow that he save his high end grinder for hatchets and wood chisels, smile.

Namaste,

Morty -_-

PS: awesome job on the scales!Last edited by Morty; 04-25-2012 at 12:00 AM. Reason: Added PS:

-

The Following User Says Thank You to Morty For This Useful Post:

DBurnette (04-25-2012)

-

04-25-2012, 01:19 AM #8

The wedge is brass. The original wedge appeared to be lead, but I preferred the brass.

Sometimes I am a bit of a luddite, but i really don't think my shaping is the culprit, as it appears the spine may be worn a little differently on one side. That's one of the surprises that comes with buying from a photo, I guess. However, your advice about the grinder is taken to heart and will no longer be a razor restoration tool!

Magic marker it is!

-

04-25-2012, 01:44 AM #9

Very nice! I like the brass wedge with the brass pins. I think it goes nice with the scales.

I have to say, I love the learning curve of this hobby.

-

The Following User Says Thank You to Cove5440 For This Useful Post:

DBurnette (04-25-2012)

-

04-25-2012, 01:53 AM #10

Hay bro I'm just like you I wanted to do it or learn it all myself. I have two straights the second one i got needed only cleaning up (little rust) the first needed new scales so thats the what I did, made scales for it, birds eye mapel with clear acrelic wedge. Then the BIG! self let down I dont know honing from hoeing so I sent THEM both out to Lynn for ME that was the way to go "for now tell I get stones and learn how" but I think i know how you fell about it, you should keep at it tell you get it. And if the blade dies an honorable death in the persuite of the art then put it a picture frame and remember it fondly, then go to the fle market and get another or do that first for a practice blade. Anyway you go I dont think you will be happy tell you get it, really get it.

Rich

-

The Following User Says Thank You to RDM2 For This Useful Post:

DBurnette (04-25-2012)

LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote