Results 1 to 10 of 25

Thread: Blade Geometry Help Required

Hybrid View

-

05-09-2012, 01:58 PM #1Junior Member

- Join Date

- May 2012

- Posts

- 15

Thanked: 1 Blade Geometry Help Required

Blade Geometry Help Required

Hi I am a new convert to straight edge shaving and SRP forum and have spent many hours reading through various informative posts on the subject (Great Site BTW!!!)

As I have succesfully shaved a few times now with my (wife's grandfather's) restored ERN Crown & Sword, and a new Dovo Prima I am hooked!

So much so, that after looking around this site, esp. at some of the restores / custom jobs that I would like to have a go myself.

I am an Mechanical Engineer working in the Formula One industry so I know my way around metal working & metallurgy, I do however require a little info regarding blade edge geometry.

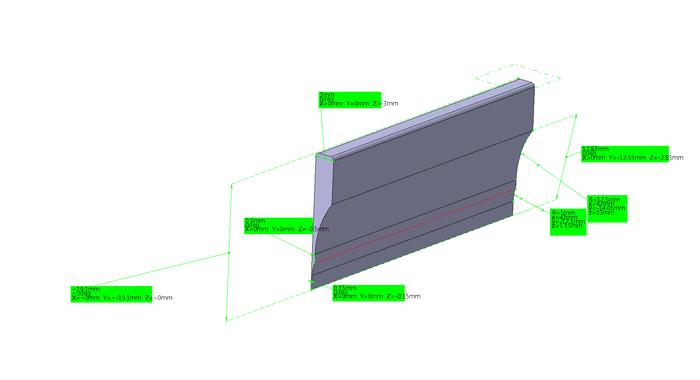

I am in the process of scheming up a custom design on CAD, and have a nearly finished design, but I have a few questions regarding the blade / cutting edge geometry.

Attached is a section of blade I have schemed up and wondered if I have my geometry correct for the grinding? (there is clearance between the stiffener and the line between spine & edge so it won't interfere with honing)

The 0.15mm edge I am leaving is so I can make sure the grinding opperations do not take off too much of the edge and I can hone that final bit producing a cutting angle of 13°

So main questions are:

1: Do you think the overall dimesions are acceptable?

2: Is a 13° cutting angle too shallow / too steep? (I am planning on using Stainless Steel 17-4PH)

3: Do I need to have a shallow hollow grind on the opposite side?

Many thanks in advance.

-

05-09-2012, 02:56 PM #2

Hello, and welcome.

This is quite a broad subject you're asking about, but in a nutshell:

1) I see that you have basically 2 hollows. Keep in mind that after you're done grinding, you need heat treatment. At this point there is still some thickness needed near the edge to prevent warping. After heat treatment, you need to grind again to the final dimensions. Virtually all razors have 1 single hollow that runs right up to the edge. Id start with single hollows if I were you.

2) A 13 degree angle is possible, but I prefer a bit wider angle, 15 to 17 degrees. this is easier to hone, and a bit stronger.

3) If you leave the other side flat, you're going for a japanese style asymmertical grind. Do a search for kamisori and you will find many pics of what that means. Now, the back side should always have a slight hollow, because otherwise it will be a disaster to hone it properly. Razors are hone by laying them flat on the hone, and if the back side is truly flat, it becomes a nightmare to remove any amount of metal.

I don't know the steel you are working with. Keep in mind that you should be able to achieve a rockwell C hardness of 58 to 62. Not less, and definitely not more if you want to be able to hone it. I'm sure I haven't covered all of your questions so feel free to ask away. It is always nice to see people starting to make their own razors.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

The Following User Says Thank You to Bruno For This Useful Post:

ScouseDave29 (05-17-2012)

-

05-09-2012, 02:58 PM #3

I would shoot for a 16 degrees total at the edge. Yes both sides need to be hollow. Once both of these criteria are met you can scale the blade to whatever width you want any where from .625 to 1 are within the norm.

Charlie

Edit: Bruno, types faster than me

-

The Following User Says Thank You to spazola For This Useful Post:

ScouseDave29 (05-17-2012)

-

05-09-2012, 04:05 PM #4Junior Member

- Join Date

- May 2012

- Posts

- 15

Thanked: 1

Many thanks for your comments!

I was indeed going for a Kamisori influence, and thought I would only hone on the one side, hence the striaght back, but may revise that.

Thanks for the advice on angle I will increase the angle accordingly.

My initial plan is to go with a 6/8" blade x 50mm (sorry I'm in UK so SI are my units of choice, apart from blade width of course).

Still a little unsure on what is best Stainless to use as I am going to try something a little different.

I work in F1, so love all things modern, but I also love the traditional side of the SE razor, however I do not have access to a forge, but I do have access to a great workshop.

Therefore I was looking at blending the traditional design style with modern manufacturing, and so I was looking at machining the blank to the desired shape, part grinding, final heat treat, then final edge prep.

I am initially thinking of trying some 17-4PH, which comes in a ready heat treated state, base hardness is ~40Rc it is very strong & tough (we use it for studs all over the car, it has a yield stress >1.1GPa, and I could possibly get the edge shot peened to work harden a little more, but looks like I may have difficulty getting an edge hardness of >58Rc?)

From what I have gathered, edge hardness is very important, but so is toughness, and yield strength so that the edge is not easily worn.

In my experience there are not too many stainless steels with a Rc>45, yet most of the stainless we use is some of the strongest steels around, and most are 38-45Rc, but with yield strengths in excess of 1.2GPa. Do you think this would be acceptable?

If not do you have any suggestions of which Stainless steels could be used, and what heat treatments would need to be applied applied?

(I have also since looked at the Forge section and gathered a lot of info from there, and am continuing to read on.)

Many thanks again, I'm learning so much as I go along!!!

-

05-09-2012, 04:28 PM #5Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

I've tried making kamisori grind razors - 4 so far, 2 turned out usable, but still not "professional" looking. I ground the back side with an 8 inch wheel - 10 or 12 would probably be better. You could try a carbon steel for your first attempts - O1 or 1095 would be good choices. Good luck, and keep us informed about your results. What F1 team do you work for?

-

The Following User Says Thank You to skipnord For This Useful Post:

ScouseDave29 (05-17-2012)

-

05-09-2012, 04:34 PM #6At this point in time...

- Join Date

- Jun 2007

- Location

- North Idaho Redoubt

- Posts

- 27,105

- Blog Entries

- 1

Thanked: 13249

Hint:

Get a traditional Kamisori, Measure, Look, Feel, Shave, ask yourself over and over Why ???

Understand that Kamisori are a different style of razor they are shaved differently and honed differently, I would suggest you learn why that is before making one..

On the other hand you can just jump right into the deep end

-

05-09-2012, 04:40 PM #7

Well, if you are interested in a couple of prototypes first, then buy some O1 or 1095 or 1084. It is easily available in the UK, and heat treating is easy.

That would get you some experience with machining. 40 HRc is plain unusable for making a razor so don't go there.

The benefit of O1 is that you can do the heat treatment yourself so you have the chance to try your prototypes without incurring the additional costs of shipping + paying for the treatment.

If you want stainless, then ATS34 is a common choice. If you're in the uk it should also be relatively easy to buy niolox in Germany.

Shipping is not expensive, and it is a knife quality stainless. Heat treating recipes depend on the specific type of razor. The people that can sell you a specific type of stainless can also tell you how it should be heat treated.

For tool steels, you can do this yourself with an improvised forge, a magnet and a bucket of oil or water. HTing stainless is more complicated and requires modern equipment.

-

05-09-2012, 04:34 PM #8

AEB-L. ATS34, cmp154 (basically the same as ats34) are all stainless steels that would work. I would use the RC hardness that Bruno recommended. Razors are not really that tough but need to be hard and abrasion resistant.

Charlie

-

05-09-2012, 04:41 PM #9Junior Member

- Join Date

- May 2012

- Posts

- 15

Thanked: 1

Cheers for the advice,

I see this as an opportunity to get a decent stainless SE, as my other half will not entertain me buying a another razor after shelling out for a new dovo and having the old one restored (both normal steel).

So if I can get a homer sorted through work at nominal cost of a couple of beers, then happy days!!!

I will see if I can source the stainless you suggest, failing that I will try O1 or 1095 series.

Oh I currently work for Force India.

I will post a CAD representation tomorrow of what I have in mind to see what you think.

Thanks.

-

The Following User Says Thank You to ScouseDave29 For This Useful Post:

skipnord (05-09-2012)

-

05-09-2012, 05:51 PM #10

Don't forget Bohler. They supply some great steals. In stainless you can use N690 which is heat treatable up to 62Hrc (I'm currently using this steel for straights that I'm also making), or for something more 'high-tech' you could use something like M390 (powder metallurgy) which would work for a razor but it's tough stuff, and you'd have to have access to professional HT facilities to properly follow the HT spec sheet.

Otherwise for high carbon steel you could use K460 which is the same as O1, and as mentioned you can't go wrong with that...

Bohlersteels UK - Tool Steel

Hope that helps.

Cheers,

- Mike

- keen to see what you produce. Machining a razor sounds great, if I had the kit that's what I would do

-

The Following User Says Thank You to MichaelC For This Useful Post:

ScouseDave29 (05-17-2012)

4Likes

4Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote