Results 21 to 30 of 62

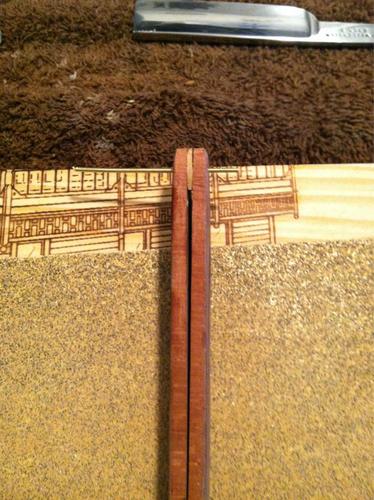

Thread: Part of my new scales

-

05-21-2012, 11:31 PM #21

I agree with u I tapered it just a second ago

-

05-21-2012, 11:45 PM #22

-

05-21-2012, 11:55 PM #23

That got alot narrower. Looks like its tapered so good to go. Can't wait to see it when it is done. Good luck.

-

05-22-2012, 12:04 AM #24Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Tyler,you need to get the scales thinner ,half of what they are,JMO

-

05-22-2012, 12:14 AM #25

I make mine usually 2.5-3mm. That usually will give them enough flex to bow when folding. Thicker scales have a harder time flexing. That was my mistake here

The scales started to pull away from the wedge and left a gap and didn't let the scales bow when folding the razor.

-

05-22-2012, 12:19 AM #26

-

05-22-2012, 12:25 AM #27

What I did before I got a belt sander was use double-sided tape and stick each scale to a block of wood and work them till I got them to the thickness I wanted. Made it easier to handle and not hurt the fingers as much. Plus I would do alittle here and there instead of trying to sand 1/4" down in one sitting.

-

05-22-2012, 12:44 AM #28

I wish I had the money for a belt sander hahah but I guess I'll just use 60grit sandpaper and glue it to scrap wood and use double sided tape and just go back and fourth

-

05-22-2012, 12:55 AM #29Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

A belt sander at this point would trash your scales in a microsecond,your close man,60 grit on a sanding block will thin them out in a couple minutes,take your time,stuff like this should be fun,not an ordeal.

-

05-22-2012, 01:15 AM #30

What's the best way to measure the thickness can u use a caliper and how think should they be

3Likes

3Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote