Results 1 to 10 of 14

Thread: Strop refinishing.

-

09-07-2012, 12:17 PM #1< Banned User >

- Join Date

- Aug 2012

- Location

- Greenwood, Nova Scotia

- Posts

- 1,144

Thanked: 116 Strop refinishing.

Strop refinishing.

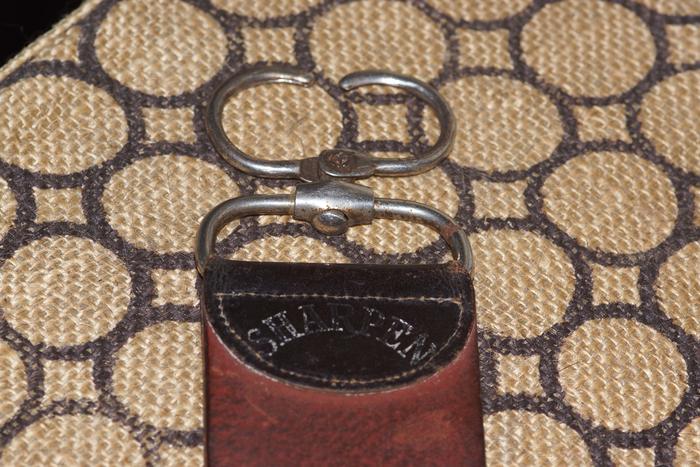

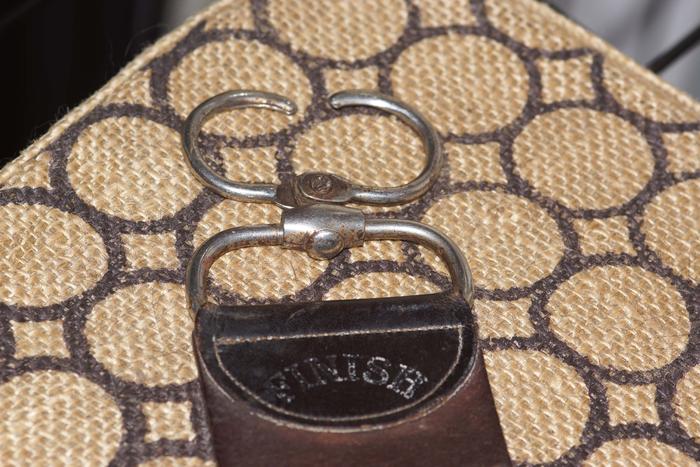

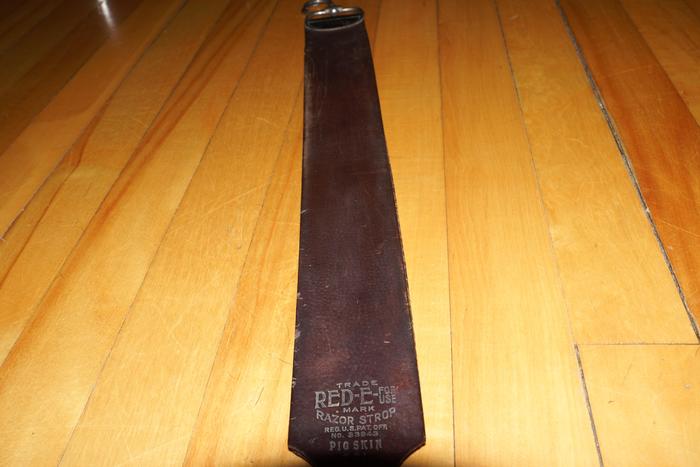

Just looking for some advice here. I have this vintage pigskin strop that is in pretty good condition. It has two sides to it. One says "sharped" the other says "finish".

There are a few minor scratches and a few little nicks on the edges but other than that the leather is in great condition. What I want to do is maybe sand the two sides down and get them back to their best performance! I was thinking about using some rougher grit on the 'sharpen' side and maybe applying some CrOx to it and then taking down the 'finish' side to bare leather and oiling it up?

What grit sand paper should I be using to achieve what I'm looking for??

Any help is MUCH appreciated!!!

-

09-07-2012, 01:51 PM #2I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

Depending on the condition you can start from 220 or 400 and go all the way up to 2000 grit.

Another way of redoing the surface is to use Pumice stone, then 600-2000 sand paper.

The job is messy, it will take a decent amount of sand paper as it clogs easy by the leather, same with the pumice stone- it will clog a lot and you will have to clean it often.Stefan

-

09-07-2012, 02:08 PM #3< Banned User >

- Join Date

- Aug 2012

- Location

- Greenwood, Nova Scotia

- Posts

- 1,144

Thanked: 116

Excellent. What about the 'sharpen' and 'finish' sides?? What should be the final grit used on each?

-

09-07-2012, 02:41 PM #4I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

Strops do not have sharpen side as far as I know. The top side is the stropping side and that is it.

Stefan

-

09-07-2012, 02:43 PM #5< Banned User >

- Join Date

- Aug 2012

- Location

- Greenwood, Nova Scotia

- Posts

- 1,144

Thanked: 116

Picture a strop that has a leather strop and linen. Instead of a linen on mine, there is another leather one. At the top (check the pics) one says 'sharpen' the other says 'finish'

-

09-07-2012, 02:54 PM #6I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

In order to sharpen you have to remove enough metal, that happens on the 1-4k stones after that is smoothing the edge pretty much.

Leather does not abrade enough to sharpen, to test that just grab a dull razor and try to sharpen on the leather, not going to work even at the slightest.Stefan

-

09-07-2012, 03:00 PM #7< Banned User >

- Join Date

- Aug 2012

- Location

- Greenwood, Nova Scotia

- Posts

- 1,144

Thanked: 116

i was thinking maybe using it for a paste side??

-

09-07-2012, 03:33 PM #8I used Nakayamas for my house

- Join Date

- Aug 2009

- Location

- Des Moines

- Posts

- 8,664

- Blog Entries

- 1

Thanked: 2591

You can paste it but still not going to sharpen the razor, just want to make sure you understand that strops do not sharpen, they can somewhat refresh an edge that is a bit off.

The other side from the pics hard to tell if it needs any work, but people usually put paste on smoothed strop. My CrO bench strop is the rough side of the leather up and it works fine for me as well.Last edited by mainaman; 09-07-2012 at 03:36 PM.

Stefan

-

09-07-2012, 04:11 PM #9< Banned User >

- Join Date

- Aug 2012

- Location

- Greenwood, Nova Scotia

- Posts

- 1,144

Thanked: 116

Understood. By the feel of it, the 'sharpen' side is definitely a coarser piece of leather.

-

09-07-2012, 04:39 PM #10Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

A lot of old strops that were double leather strops had 'sharpen' on the side that had had some sort of treatment applied to it. Quite a few manufacturers impressed a very fine abrasive into the surface of the leather - Carborundum Co., Roma, Kropp, Scorcher etc, - by putting the leather between rollers with enough force to push the grit in. This type often feel like harder leather on the sharpen side because the act of rolling it under pressure does in fact compress the leather and harden it. They used to hammer boot sole leather for this reason. You could buy a refreshing paste that had the abrasive suspended in it for applying to the strop when it glazed up. If you want to keep a 'sharpening' side then use something like chrome oxide on it, but remember to only do five - 10 laps and keep it taut. Then finish on the 'finish' side after wiping off the blade to avoid cross-contamination.

Regards,

Neil

-

The Following 4 Users Say Thank You to Neil Miller For This Useful Post:

brooksie967 (09-07-2012), Eekspa (09-09-2012), Geezer (09-14-2012), mapleleafalumnus (09-12-2012)

3Likes

3Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote