Results 31 to 40 of 45

-

02-27-2013, 01:19 AM #31

-

02-27-2013, 01:40 AM #32

Most vintage silver scales are fairly stamped sheets. Super light.

If solid, would be too heavy? Even lined with Ivory They are light!

What about making a die to stamp them?

Sorry! Late to the game!"Don't be stubborn. You are missing out."

I rest my case.

-

02-27-2013, 05:48 AM #33

i have that same wade and butcher razor, but mine needs to be cleaned up. did you make the scales how can i go about making a set like those? i can see that on the 3rd picture the scales appear to be plastic (micarta) and that the metal is just stamped onto them. are the wade's scales done in the same way.

-

02-27-2013, 06:12 AM #34

rocarule,

Here's Sharptonn's John Nowill Sterling over Ivory Cammell and Laird Pair where he talks about those scales.

Jonathan

-

-

02-27-2013, 02:22 PM #35

I would surely like to see how they made them. I can see a die with silver sheet and stamped out. possibly poured into a mold, cast and then finished. I feel a study on how all silver objects are made would yield the answer. Round, hollow, thin sterling objects, such as this brush, were probably made in 2 halfs and silver-soldered together, seamlessly finished.

OR, we could ask Neil Miller!"Don't be stubborn. You are missing out."

I rest my case.

-

02-27-2013, 05:46 PM #36

I would say the brush handle is probably made in 3 pieces, one bowl like part holding the knot and then 2 press decorated halves soldered together, as you suggested.

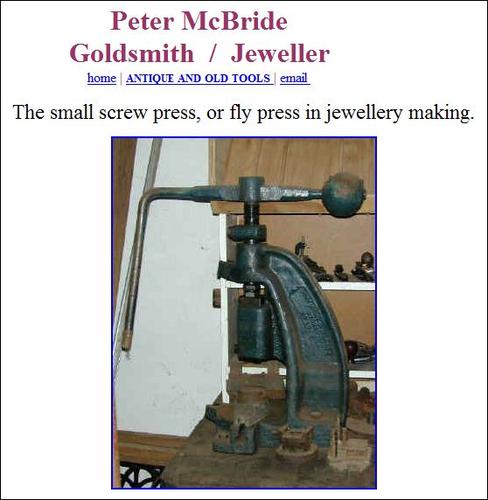

Early presses where usually the screw type with a large "T" on top with heavy metal balls on it to give it a great mass.

http://sonesgarden.se/GIVA-sidan/Int...Skruvpress.jpg

Dangerous contraptions!Hur Svenska stålet biter kom låt oss pröfva på.

-

02-27-2013, 06:03 PM #37Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

Sterling silver used to be bought in bar form or plate form from the manufacturers. If it needed flattening into a thinner plate, or expanded into a plate from a bar, it was put repeatedly through a rolling mill (like a thin all-steel mangle). It could only be reduced a bit at a time - each pass through the rolling mill work-hardened it, so it had to be annealed again before the next pass, or it would fracture. So, to save work it was bought in a size and thickness comparable with its finished form.

If many scales were to be made, a wax model was made (the wax is much harder than normal wax) and from that a pair of dies were cast. Jewellers used a small version of a fly-press, with this they stamped out the designs into silver sheet. It was a fast process, hence 'flying off the press' or 'flying them out' as an expression of speed. After suitable handwork, the article was ready. The main problem with press work is the stress and strain imposed on the sheet - you are liable to get folds and wrinkles with complicated designs.

There were many types of press, but most were small due to limited workspace and the fact that soft, malleable metals were being worked, so the weighted arm fly press was a bit of a rarity.

If only one thing was to be made, then a design was copied onto the back of the sheet and the face was put onto a prepared bed that had a form of asphalt bitumen on it - it was heated and the article pressed in close contact with it. Very small punch sets were used - like thin, round ended chisels for example, looking a bit like doming daps and used for ball shapes and foliage, and chasing chisels for lines. There were very many different shapes. Most of the pattern was carefully done from the back, with some of the work done on the front - mainly patterning with scrapers and dot-puches and details. It was very precise, exacting work, but jewellers did it all the time. In fact they would think nothing of making large bowls out of flat silver sheet merely by hammering, or 'raising' as it is called. Of the course, the work had to be periodically annealed, or it got brittle and fractures occurred.

The last technique was making a lost wax mould (or similar) and casting. This still needed quite a lot of handwork to finish off, and it resulted in a heavier, more expensive piece, which was not always desirable.

In all likelihood the thin scales were raised by hand. When you consider that jewellers made chains by making every single link, and tiny links at that, and some chains that seem to have solid links have been formed by many pieces soldered together and are actually hollow, a set of scales would not be too arduous to contemplate.

As for the brush handle, that was almost definitely a two-piece solder job - with good silver-soldering you can't easily see the seam. The brush holding bit was separate.

Regards,

NeilLast edited by Neil Miller; 02-27-2013 at 06:14 PM.

-

-

02-27-2013, 06:24 PM #38Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

RE: fly-presses - when I was a boy I used to work one in a 'light engineering' factory called the Salisbury Forge. It was one of my first jobs, and I operated this huge press, about 4 feet high with a cross-piece to which cannon-ball weights had been added for extra 'umph' - in between running errands, making the tea for everyone and rolling cigarettes for those who were on 'piece-rate' and didn't want to lose any time.

When I first started, they told me a man would be coming to see how fast I could go. I didn't want to look bad, so when he turned up with his clipbook and stopwatch I went at the press like the clappers.

He had an odd, bemused/amused expression on his face. He asked me if I usually went that fast, so I said no - this was a special occasion. He must have taken pity on me and knew I had been set up by the old lags, because he halved my rate and told me that's how many I would have to do per hour. Even then it took some doing. Riots due to lack of tea-making and cig-rolling soon ensued.

Regards,

Neil

-

02-27-2013, 06:31 PM #39

I once read about a goldsmith being accused for murder, he had two helpers working for him and they where "running the fly wheel", while he was managing the tooling.

One of the boys got caught on a hook on the wall and when the ball came behind him he was crushed!

They said the goldsmith had a to small a workshop for that press.

In Stockholm they have a 1700 era goldsmiths shop with one of those, it's quite fun to operate but you have to be ready to duck when it hits the bottom, they come swinging back really fast!Hur Svenska stålet biter kom låt oss pröfva på.

-

02-27-2013, 06:42 PM #40

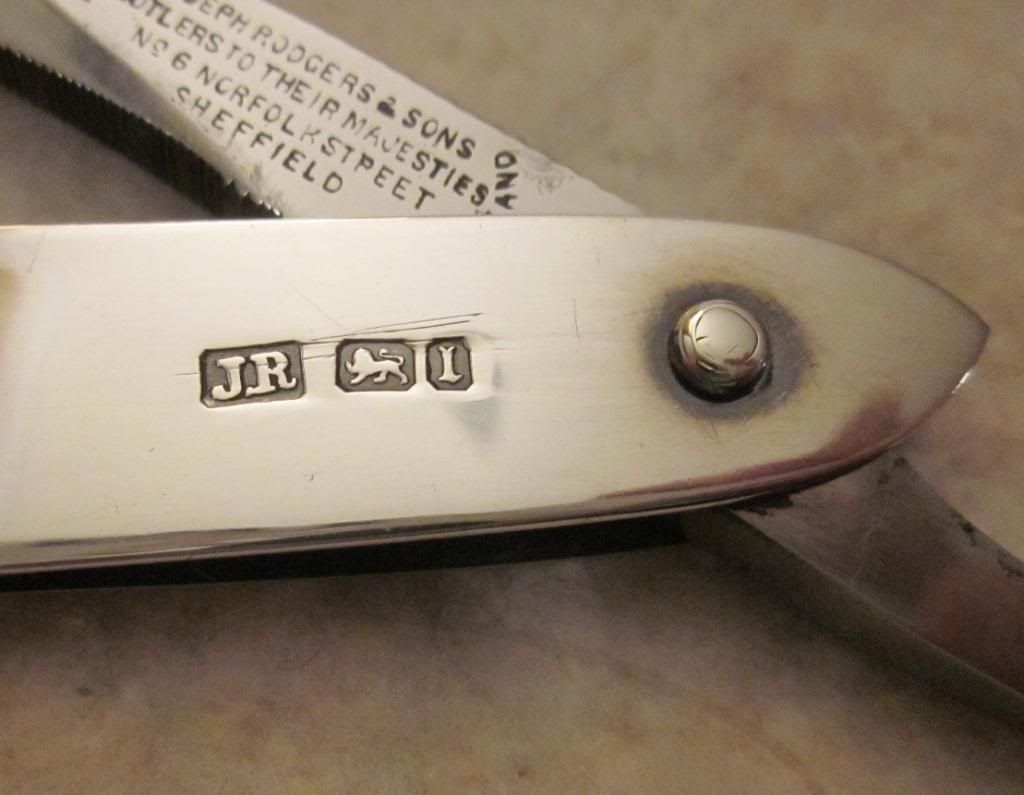

Joseph Rodgers with solid silver scales, spotted on fleabay not too long ago.

Really gorgeous imo and I thought they'd fetch more than they did.

65Likes

65Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote