Results 1 to 10 of 25

Thread: home made dome washer

-

03-18-2013, 01:11 AM #1Senior Member

- Join Date

- Feb 2007

- Posts

- 392

Thanked: 105 home made dome washer

home made dome washer

Was looking for razors and found this instead. For $2.00 I could not pass it up, and I like old tools. Drilled 1/16 hole in the 0.020 brass sheet first then the pin on the punch centers on that. Put them in a doming block and you got a dome washer. smash um flat and you got a thrush washer. It is a little big a 9/32 but I am going to see about getting some other size punches for it. Might be a lost cause since it is about 100 years old. Tim

-

The Following 5 Users Say Thank You to oldblades For This Useful Post:

Geezer (03-18-2013), JP5 (09-08-2015), nipper (03-18-2013), randydance062449 (03-19-2013), spazola (03-18-2013)

-

03-18-2013, 04:17 AM #2

maybe the different size punches can be fabricated by a machinist if you have no luck finding them. I have no idea if that's possible; the extend of my knowledge is watching American Restoration and they fabricate stuff all the time

-

03-18-2013, 07:10 AM #3aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

You think it's still under warranty?

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

03-18-2013, 01:36 PM #4Senior Member

- Join Date

- Feb 2007

- Posts

- 392

Thanked: 105

If you have a budget like American Restoration any thing is possible

I think the warranty is up, but it still works.

Thank you all

Tim

-

03-18-2013, 04:35 PM #5Senior Member

- Join Date

- Jun 2011

- Posts

- 222

Thanked: 30

Its a power punch...I use one for my washers too. You can pick up a brand new one at Michael's craft store for $20 comes with six or eight different size punches. Dapping block is exactly how I round out the dome.

-

The Following User Says Thank You to jumbojohnny For This Useful Post:

Sandycrack (01-13-2014)

-

03-18-2013, 11:46 PM #6Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

Sorry that I don't have pics for this......

To reduce the diameter of the washers put a bunch of them on a 1/16" rod. Cut 2 pieces of tube with an inside diameter of 1/16". Each piece about 1/2" long. Put those on each end of the solid rod & push up tight on the washers. Next get some small collars w/set screws that will fit over the 1/16" rod. Put them on each end and push up tight against the short pieces of tube. Tighten them down. Now take 2 more pieces of the tubing on put on the rod. These 2 pieces will be free wheeling and what you hang onto as you bring the washers up to a spinning sanding wheel.

I do have to take a pics of this. It makes it much easier to understand.Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

03-18-2013, 11:48 PM #7Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Pics would be great,Thx

-

03-19-2013, 04:21 AM #8Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

OK, here are the pics of the process. This is pic heavy.

This is the tool, available from Harbor Freight.....

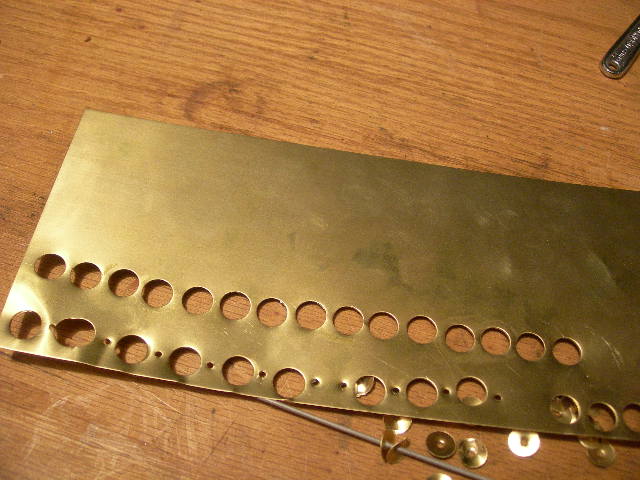

I used a big die for picture clarity and punched out a bunch of washers from brass sheet with a thickness of 0.01

That gave me these washers, kinda rough looking

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

The Following 3 Users Say Thank You to randydance062449 For This Useful Post:

jumbojohnny (03-19-2013), Lemur (03-19-2013), SirStropalot (03-19-2013)

-

03-19-2013, 04:23 AM #9Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

Then I put them into the doming block

after the doming block ( sorry, forgot to take a pic but it cleaned them up a lot)

I cut some 1/16 brass rod, some 1/16 brass tube and the collars with set screws then pushed the washers onto the rod and tightened down the collars. Here is a pic of it assembled....

Last edited by randydance062449; 03-19-2013 at 04:31 AM.

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

The Following 3 Users Say Thank You to randydance062449 For This Useful Post:

jumbojohnny (03-19-2013), Lemur (03-19-2013), SirStropalot (03-19-2013)

-

03-19-2013, 04:35 AM #10Hones & Honing

- Join Date

- May 2005

- Location

- Saint Paul, Minnesota, United States

- Posts

- 8,023

- Blog Entries

- 1

Thanked: 2209

Then off to the sander....

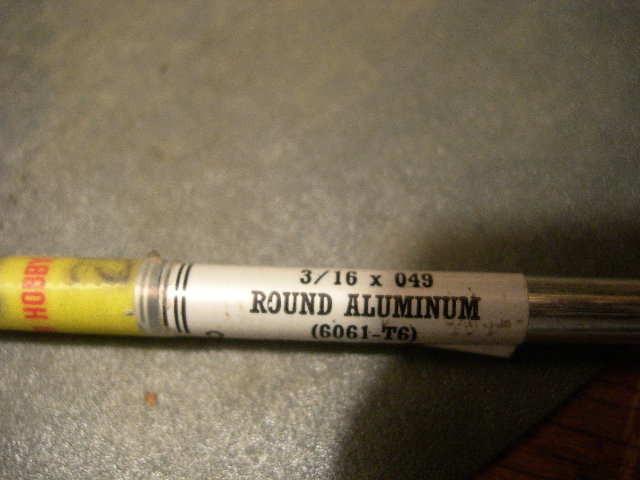

But the wheels were freewheeling to much so I took off the brass tube and cut some thick aluminum tube so there was more friction against the collars so they did not free wheel as much..

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

Randolph Tuttle, a SRP Mentor for residents of Minnesota & western Wisconsin

-

The Following 4 Users Say Thank You to randydance062449 For This Useful Post:

jumbojohnny (03-19-2013), Lemur (03-19-2013), RezDog (01-09-2014), SirStropalot (03-19-2013)

60Likes

60Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote