Results 1 to 10 of 20

Thread: Divot in anvil size

-

06-06-2013, 01:33 PM #1

Divot in anvil size

Divot in anvil size

To the guys using a piece of steel (or whatever material) as an anvil to peen their razor pins, what size divot have you found works best to rest the opposite side for the hammering in? I can't remember what I've used, and I have a project that I need to be right the first time.

-

06-06-2013, 01:38 PM #2Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

I use no divot .

-

06-06-2013, 01:44 PM #3

Thanks Bill. Do you find that it flattens the rounded look of the downside pin face at all?

Btw, I read your reply in a very heavy, fake sounding Russian accent for some reason. I think I need sleep.

-

06-06-2013, 01:47 PM #4Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

I polish my pins after peening,It may flatten them a tad but has never been a problem

-

06-06-2013, 01:59 PM #5

I find that the divot does more to hold things still than it does to round or flatten the pin. But a nice advantage is that if you drill to a proper depth, the hole can serve as a guide for when you cut the rod to size before you start hammering. There are other ways to make that measurement, to be sure, but I think that is a slick way to do it.

-

06-06-2013, 02:38 PM #6

Yes, but what is that correct size/depth? Lol.

Here's what I'm making if anyone is interested.

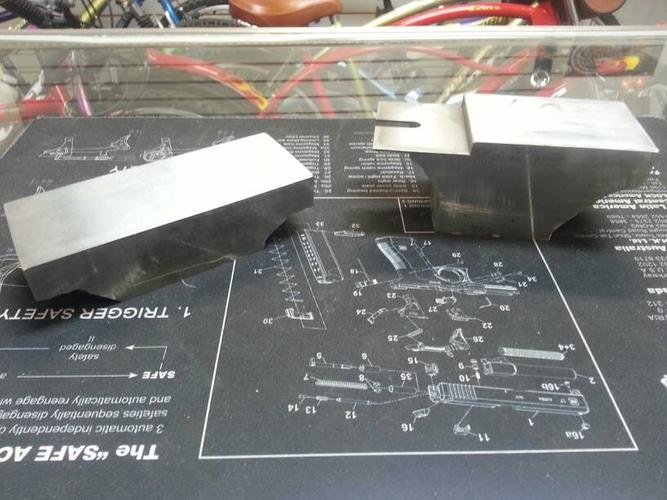

They are A2 tool steel. The one in the left its where I'd put a small divot. I don't do many razors anymore, but I figured if I'm making them, I might as well make them to encompass everything I do. The one on the right needs a couple holes drilled in the back of it, for pocket knife pins to be driven out of the bolsters. The will be mounted to a piece of 1" mild steel. If anyone knows of a cheap heat treater, let me know. They need to be in the low to mid 50s Rc.

-

The Following User Says Thank You to medicevans For This Useful Post:

spazola (06-08-2013)

-

06-06-2013, 04:35 PM #7Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

I wonder what the RC is now? Tool steel is often used without being heat treated, so you may not need to do it.

-

06-06-2013, 04:44 PM #8

As delivered state is usually around 215 brinell hardness. That's somewhere south of 20 Rockwell. It will need to be around 600 hb, or 56 Rockwell.

-

06-06-2013, 04:55 PM #9Senior Member

- Join Date

- Mar 2011

- Location

- Corcoran, Minnesota

- Posts

- 665

Thanked: 170

Thanks - now I know. Guess I'd better get busy and heat treat the lathe chisels I've made.

-

06-06-2013, 05:10 PM #10

10Likes

10Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote