Results 61 to 70 of 270

-

05-08-2015, 10:41 AM #61

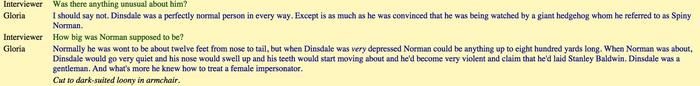

Gentlemen, I believe we must turn our attention to the works of Spiny Norman on the Maintenance and Care of Your True Wedge.

Last edited by WW243; 05-08-2015 at 11:07 AM.

"Call me Ishmael"

CUTS LANE WOOL HAIR LIKE A Saus-AGE!

-

05-08-2015, 06:29 PM #62

-

05-08-2015, 07:07 PM #63

-

05-08-2015, 07:47 PM #64

I have a friend who inherited a black ark from his grandad-it was dished out. Apparently that is the stone grandad used to hone his razor, which was a hollow ground Clauss. Since my friend's dad, who saw his father hone, demonstrated to my friend on the same hone how grandad did it. Of course, memory is a funny thing. Anyway, some were still honing with dished hones even around the 1900's so they could have been doing it earlier.

From their stillness came their non-action...Doing-nothing was accompanied by the feeling of satisfaction, anxieties and troubles find no place

-

05-08-2015, 07:49 PM #65

It's faster if you rub the stones together in figure 8 patterns - just like you use a lapping plate. It works fine for flattening.

Or ask Spiny Norman - he's watching you... Some people never go crazy. What truly horrible lives they must lead - Charles Bukowski

Some people never go crazy. What truly horrible lives they must lead - Charles Bukowski

-

05-08-2015, 10:26 PM #66

Chris

It seems like two similar stones could work but they just don't do it all. Figure 8's help but the 3 stone method is the accepted one. A granite block can work when flattening softer stones, cement can work for softer stones, but with 2 similar stones they just keep making each other a little bit less rounder and never really get flat. Remember same material.

This webpage describes it very nicely.

Alex

https://fairwoodworking.wordpress.co...ten-my-stones/

-

05-09-2015, 01:57 PM #67Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

-

05-16-2015, 11:32 PM #68Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Nope, not correct. You can rub two stones together in all different directions and they will still develop a curve. Think spherical surface. This is what will happen. Every time. You need 3 stones to get perfectly flat surfaces, as Alex pointed out.

Additionally, if it's done with only the stones and without a loose grit abrasive such as SiC, it doesn't work very well unless the stones are of similar grit and hardness. If SiC or similar loose grit is used, this is less of a problem.Last edited by eKretz; 05-16-2015 at 11:38 PM.

-

05-18-2015, 01:14 AM #69

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

05-18-2015, 01:24 AM #70Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Obviously you didn't bother to read the link posted by Alex above. There's no sense reiterating what's already written there.

BTW, the same method was used in the 1800's to lap gage blocks used in machine shops to size and flatness of somewhere in the neighborhood of .00005" before today's high precision machinery was available.Last edited by eKretz; 05-18-2015 at 01:28 AM.

426Likes

426Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote