Results 31 to 40 of 45

Thread: Hot & Shiny WIP

-

06-01-2015, 02:02 PM #31

No nozzle tip but a little bit of a change in the diameter and surface as it goes through the side wall of insulation. It is just a piece of black pipe. I run mine at tank pressure no regulator, some of the other guys are using regulators I do not know what they are doing pressure wise.

It is just a piece of black pipe, air slots, mig tip letting propane in on one end, and welded to the other.

I always thought if I made another I would not weld the pipe on, but after seeing how well Dan's forge works I am not sure. I am beginning to think is 6 of one or a half dozen of the other.

Charlie

-

The Following User Says Thank You to spazola For This Useful Post:

Substance (06-01-2015)

-

06-01-2015, 04:11 PM #32

-

06-01-2015, 04:38 PM #33

-

The Following User Says Thank You to spazola For This Useful Post:

Substance (06-01-2015)

-

06-01-2015, 04:55 PM #34

In Belgium and Germany, it seems common to use propane or butane canisters to make a forge. They cut off both ends, mount it horizontally, coat it like above, and shove a burner in the middle. They do this because those canisters are very strong, and cheap. I have seen pics of Achim making wootz by setting one of those things vertically, place the crucible in the middle, and put a tile on top of the opening.

Most smiths I know here work this way. People in the arts and crafts business tend to use regular coal. So far I am the only bladesmith I know here in this area who uses charcoal.Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

06-07-2015, 09:05 AM #35

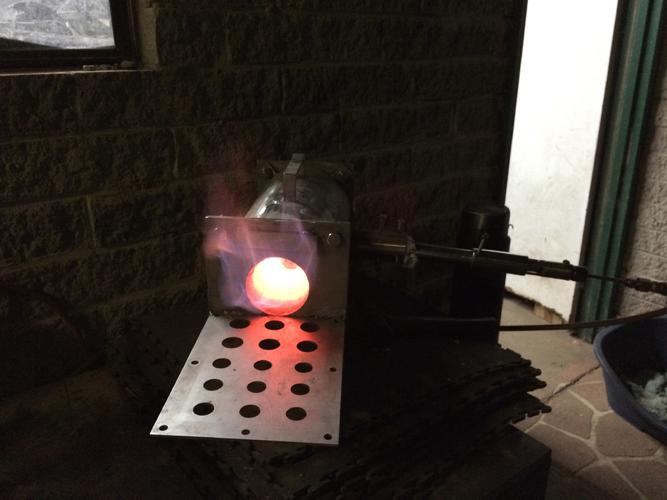

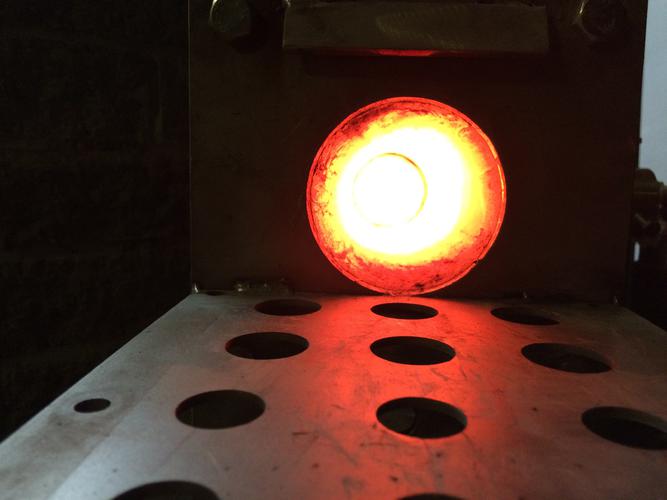

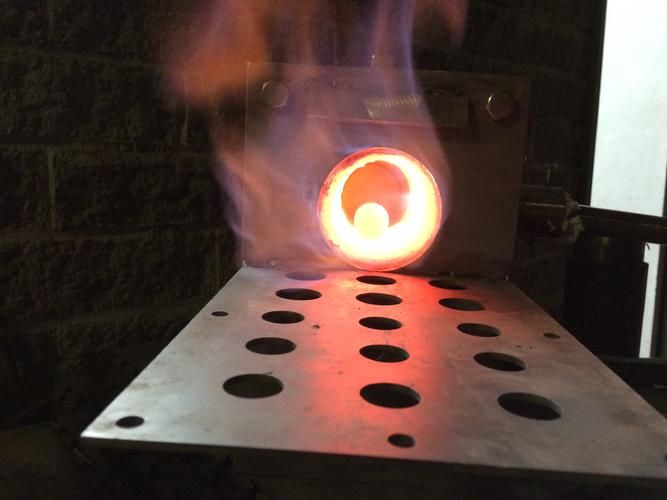

All Fired up

1st was a cure run

Then heated to critical (non magnetic) a couple of punches which are now in vermiculite annealing so I can try make a makers mark stamps

Last edited by Substance; 06-07-2015 at 10:41 AM.

Saved,

to shave another day.

-

The Following User Says Thank You to Substance For This Useful Post:

sharptonn (06-10-2015)

-

06-08-2015, 09:07 AM #36

Had a play with a piece of 1075 1/4"X1"x4" and forged this

Saved,

Saved,

to shave another day.

-

06-08-2015, 01:48 PM #37

In my opinion everything turned out. Congratulations!

-

The Following User Says Thank You to Gipson For This Useful Post:

Substance (06-08-2015)

-

06-08-2015, 07:25 PM #38

Surprising how far the piece of steel forged out to

The tail is long and the blade is hugeSaved,

to shave another day.

-

06-09-2015, 01:57 PM #39aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

If you quit now, you may not end up with the fatal disease. Mike warned me & I didn't listen...now I'm incurable. Moving and grinding steel is very addictive. You have been warned.

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

-

The Following User Says Thank You to ScottGoodman For This Useful Post:

Substance (06-09-2015)

-

06-09-2015, 08:52 PM #40

thanks Scott but there's no hope for me

so I'll take your warning & raise you by adding a Metal Fabrication & 1st class welder trade on top,

which I was hooked on the 1st time I had a go at metal work & welding in high school in 1984,

I loved doing the odd bits of blacksmithing in the boat yards as an apprentice.

& My grandfather was a life long trade Blacksmith.

so it's deep in my blood & I know I'm screwed,

now to add fuel to the fire, I have the bride showing things she finds on the net & would like made lucky most won't fit in my mini forge LOLSaved,

to shave another day.

-

The Following User Says Thank You to Substance For This Useful Post:

sharptonn (06-10-2015)

89Likes

89Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote