Results 21 to 30 of 32

Thread: a crap ton of blades

-

05-16-2015, 11:00 PM #21

Being a boiley & welder by trade but now staff based I sometimes miss the smell of burning metal

Nice carbon content in them sparks LOLSaved,

to shave another day.

-

05-19-2015, 08:13 PM #22

Very very nice...drooling over those monster choppers!!

-

The Following User Says Thank You to yardie For This Useful Post:

silverloaf (05-19-2015)

-

05-29-2015, 03:19 PM #23Senior Member

- Join Date

- Feb 2015

- Location

- Florida

- Posts

- 507

Thanked: 49

You did a good job of nesting those blanks, but as Dr. McCoy would say, "Dammit, man, get yourself a portaband saw!!!"

-

05-29-2015, 04:54 PM #24

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

07-08-2015, 05:35 PM #25

I'm so glad I'm not the only one drilling holes and bashing things about!

-

07-08-2015, 05:46 PM #26

-

09-24-2015, 08:02 PM #27Senior Member

- Join Date

- Jul 2015

- Posts

- 143

Thanked: 9

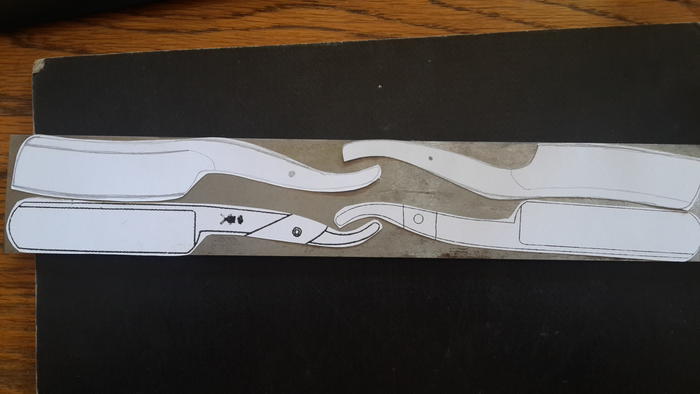

One tip... although i have to say i dont think it is faster... it is less of a material waste... is a tip i got from a knifemaker Bertie Rietveld. He suggests grinding with a angle grinder the rear half or two thirds off most of your bimetal hacksaw blade... use cutting fluid and voila! A metal coping saw... i cut these out this morning... i have two blades a normal and reduced width one to save the reduced blade on the long straight sections... a sturdy hacksaw is a must though... two hacksaws would be better

I frequently leave only about 2mm between patterns and do 1/2" radii fairly easily... just saw as if using a coping saw or jewelers saw around a curve... slower progress plus side pressure and you have a curve... blades last quite long if you are somewhat mechanically sympathetic...

-

09-24-2015, 08:27 PM #28

-

09-24-2015, 08:49 PM #29Senior Member

- Join Date

- Jul 2015

- Posts

- 143

Thanked: 9

This mornings batch... and a cut out blade... obviously not one continuous cut, but not 20 small ones either... ready to finalise on the grinder... dont have pics of the sawblade though... think about 4mm blade except for the inch next to the blade eyes... and a gradual taper to do bit of stress relief...

-

09-24-2015, 08:57 PM #30Senior Member

- Join Date

- Jul 2015

- Posts

- 143

Thanked: 9

Btw i looked at your photos again and i am not sure you would have gained much using this technique except avoide some drilling and swopped quite a bit of grinding for some sawing that is not that slow...

102Likes

102Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote