Results 1 to 10 of 35

Thread: Frankensteel razor #1

Hybrid View

-

12-13-2017, 03:52 AM #1

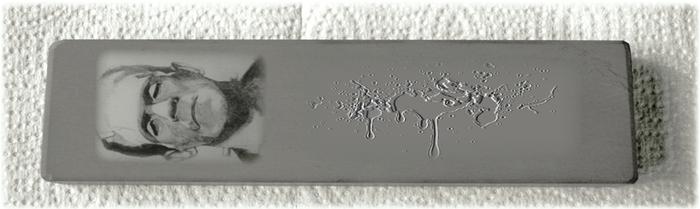

Frankensteel razor #1

Frankensteel razor #1

The story of this little project has kind of been split between two threads up until now, so I figured it made sense to bring it together here.

Long story short, a question was asked a while back about whether anyone had tried melting down and re-using steel from vintage Sheffield blades. I don't have any kind of smelting experience or equipment, so that was well beyond my scope, but it got me thinking that it should be possible to forge weld together a billet made up of vintage blades. Since I had a small pile of blades that were, for a variety of reasons, beyond salvation, I decided to give it a shot.

These are the blades: there's a W&B FBU ( honed beyond recognition, poor thing ), a DD, couple Joseph Allens, a Boker, and a bunch of random others. So I strayed from the original idea in that they're not all Sheffield blades, but they are all vintage 19th/early 20th century blades. I rejected one of the blades as I didn't like the way it sparked when I was grinding it, so ended using 11 of the original 12.

I flattened the spine and tail, ground off the blades (which were essentially foil & scale at this point), and cut them off at the pin hole to avoid cold shuts.

Then stacked them, welded the billet ends, and got the forge nice and hot

They forge welded *really* nicely and so I ended up with an 11-layer billet of vintage razor steel.

It was in original condition, faded red, well-worn, but nice.

This was and still is my favorite combination; beautiful, original, and worn.

-Neil Young

-

The Following 14 Users Say Thank You to Cangooner For This Useful Post:

BeJay (12-13-2017), BobH (12-13-2017), Dieseld (12-13-2017), HARRYWALLY (12-13-2017), Hirlau (12-13-2017), JOB15 (12-15-2017), markbignosekelly (12-13-2017), MisterClean (12-13-2017), outback (12-15-2017), spazola (12-16-2017), Substance (12-16-2017), tintin (12-13-2017), TrilliumLT (12-13-2017), xiaotuzi (12-16-2017)

-

12-13-2017, 03:58 AM #2I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

Ok you crazy guy! You have my attention.........

Burls, Girls, and all things that Swirl....

-

12-13-2017, 04:01 AM #3

I was really impressed with how well the steel welded. At least the first weld. My decision to fold it and double the layer count will come back to haunt me...

But the result was a nice solid billet

This turned into a vaguely RSO

Before this, I had only tried to make one razor, and I screwed that one up by getting it too hot grinding, resulting in a crack. So I'm determined to take this one as slow and easy as possible. Less grinder work, and more hand sanding was the idea.

A crap ton of wet/dry and two sore hands later, it was getting pretty close to what I wanted: big and with a nice heavy grind

It was in original condition, faded red, well-worn, but nice.

This was and still is my favorite combination; beautiful, original, and worn.

-Neil Young

-

The Following 14 Users Say Thank You to Cangooner For This Useful Post:

BobH (12-13-2017), Dieseld (12-13-2017), HARRYWALLY (12-13-2017), Hirlau (12-13-2017), Leatherstockiings (12-13-2017), markbignosekelly (12-13-2017), MisterClean (12-13-2017), MrZ (12-16-2017), outback (12-15-2017), Phrank (12-13-2017), rolodave (12-13-2017), ScottGoodman (12-13-2017), spazola (12-16-2017), xiaotuzi (12-16-2017)

-

12-13-2017, 04:04 AM #4

Beautiful - send it to me when you're done, you know I crave Sheffield steel....great job, and I bow and defer to your efforts in stepping into the Time Machine.....

-

12-13-2017, 04:06 AM #5

Now all you need is the famous FrankenPhig.

-

12-13-2017, 04:15 AM #6

And this is where the decision to fold the billet came back to bite. About 2/3 of the way to the toe, you can see that there's a bad weld. It's on the side, and not right on the edge, so not a total disaster, but not good. The good news is that it survived hardening. The bad news is that the bad weld looked much worse after tempering.

And then, when going to do the final grind... disaster! Or, potential disaster... The bad weld extended way, way further back into the billet than I had hoped.

So... back to the grinder, and plan B. No more heavy grind for this razor unfortunately. As I chased the bad weld back in search of solid steel, the grind got lighter, and lighter, and lighter. This all was making me very nervous because a) I have no proper tools for hollow grinds b) I have no experience doing hollow grinds, and c) by this point, I really just want to get at least one shave out of this thing!

So the dodgy weld got smaller, the blade got thinner, and I got more nervous. And this is where I stopped for the night.

Remember when I was aiming for a heavy grind? Looks like I'm heading for a completely unintentional kamisori grind on this guy. This is turning into a really strange razor... but it ain't dead yet!

It was in original condition, faded red, well-worn, but nice.

This was and still is my favorite combination; beautiful, original, and worn.

-Neil Young

-

The Following 5 Users Say Thank You to Cangooner For This Useful Post:

BobH (12-13-2017), Dieseld (12-13-2017), Hirlau (12-13-2017), MisterClean (12-13-2017), Substance (12-16-2017)

-

12-13-2017, 04:18 AM #7

I like it the way it is, shows character.

Frankenstein himself had a lot of scars.

-

The Following User Says Thank You to Hirlau For This Useful Post:

Cangooner (12-13-2017)

-

12-13-2017, 06:19 AM #8

Throw some JB Weld in there and call it a day! It's a thing of beauty!

-

The Following User Says Thank You to jmabuse For This Useful Post:

Cangooner (12-13-2017)

-

12-13-2017, 06:32 AM #9

I mean, the key question is, will it shave?

-

12-13-2017, 09:23 AM #10aka shooter74743

- Join Date

- Sep 2009

- Location

- SE Oklahoma/NE Texas

- Posts

- 7,285

- Blog Entries

- 4

Thanked: 1936

The ultimate restoration!

Southeastern Oklahoma/Northeastern Texas helper. Please don't hesitate to contact me.

Thank you and God Bless, Scott

213Likes

213Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote