Results 31 to 40 of 43

Thread: Grinder accesories and ideas

-

02-14-2021, 06:19 PM #31

Here is a few pics of the full hollow I went a little too far. The difference between success and failure was leaving enough material to hand sand. Mind you this a 3rd attempt at full hollow this thin. The next razor should be a success but we will see.

There is still some layout dye that I didnít thoroughly cleaned off. I may just leave it as is and clean up the tang and spine some then just shave with it to check my heat treat for edge retention. I always learn more from my mistakes.

[ATTACH=CONFIG]329627[/ATTACH

-

The Following User Says Thank You to jfk742 For This Useful Post:

spazola (02-14-2021)

-

02-14-2021, 10:43 PM #32

-

The Following User Says Thank You to bluesman7 For This Useful Post:

jfk742 (02-17-2021)

-

02-16-2021, 05:43 AM #33

-

02-17-2021, 03:11 AM #34

A checkering file. I use a file guide to get it started, once the first set of tracks is established you can move on down, registering on your file in the already established cuts. I think the size is 00 which is 20 lines per inch, iirc.

-

02-19-2021, 06:01 PM #35

I have my sights on a 9" 1į conical disk grinding surface now.

-

02-22-2021, 06:33 PM #36

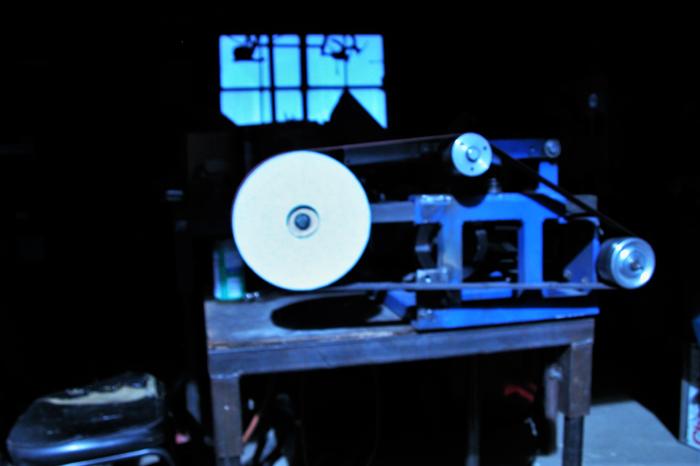

9" beveled disc

Hard to see, but here is the disc installed on my 2x72.

Last edited by bluesman7; 02-22-2021 at 08:34 PM.

-

02-26-2021, 03:20 AM #37

What is the purpose of the conical wheel?

-

02-26-2021, 04:54 AM #38

-

-

03-06-2021, 03:19 PM #39

I'm in the process of putting a flat disc on the other side of the wheel.

I'm doing this mainly for two reasons, I can have two different grits mounted, and having discs on both sides makes them effectively turning in opposite directions (picture grinding a flat grind knife edge up on either side).

A third but less important reason is that I figured I may as well make this second disc flat to help evaluate the difference between flat and beveled and see if there are uses where flat is better. I can easily bevel it in the future if I need or want to.Last edited by bluesman7; 03-06-2021 at 03:29 PM.

-

03-27-2021, 04:23 PM #40

The 9" dual sanding disk/wheel rocks for general shop work. I have three different grits turning at the same time.

88Likes

88Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote