Results 1 to 10 of 41

Hybrid View

-

10-09-2014, 10:13 AM #1Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Here are some photos of some more trials today with slurry on water. You can see with the slurry it finishes up as a hazy mirror. I finished this test piece with figure eights. Really a neat stone, wish I knew what the heck it was. I started this test with a 2,000 Shapton Pro then went straight to the new stone with an Atoma 400 slurry. This stone has really good feel on the water/slurry, I really like it. Took about 150 laps IIRC to remove every last one of the Shapton 2,000 scratches. It goes much faster if I start out at a 5,000 or 8,000 finish. I'm a little leery of trying to finish a razor on slurry though as I've never done it before.

-

10-09-2014, 02:40 PM #2Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,401

Thanked: 4822

When I first started rock hounding I tested the ability to cut steel on knives. Your piece of test steel is interesting. Is it tempered steel? If you are not wanting to use a razor use a knife or a chisel. Chisels have such a wide bevel that the scratch pattern shows quite well.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

Blistersteel (10-09-2014)

-

10-09-2014, 05:47 PM #3Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

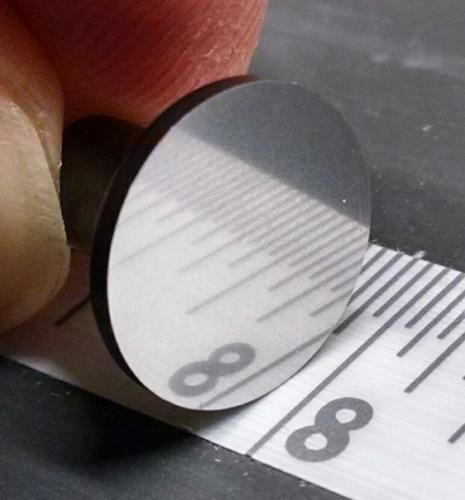

Lol, yes of course it's heat treated. It would be kind of pointless otherwise. The item in question is a contact point for a dial indicator made by a company called Starrett. It can only just be scratched with a metal cutting file, which indicates that it is below the hardness of the file, (usually ~65HRc) but not by much. They need to be very hard as they are often dragged across steel surfaces in a gritty environment (machine shop) and otherwise would wear out in a matter of hours. I have also used knives and chisels for testing, and as indicated have already shaved a couple times with a razor honed on the stone. I actually started my testing on the metal cutting file, to make sure the stone could cut something that is glass hard.

The reason I use the test piece I use is that it is easy to keep flat and aligned to the stone, and I have a couple so I can compare finishes from stone to stone also.Last edited by eKretz; 10-09-2014 at 05:53 PM.

-

10-11-2014, 12:19 PM #4

Does it float?

******************************************

"The early bird gets the worm but the second mouse gets the cheese." -Steven Wright

-

10-11-2014, 12:41 PM #5

I knew this would come in handy some day:

State v. Durham, 323 N.W. 2d 243, 245 (Iowa 1982) (holding that a straight razor is per se a "dangerous weapon").

-

10-11-2014, 12:43 PM #6Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

The stone does not float.

-

The Following User Says Thank You to eKretz For This Useful Post:

JoelLewicki (10-16-2014)

-

10-11-2014, 01:49 PM #7Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Tried a slurry honing but wasn't happy with it. I was easily able to shave with it but wasn't as smooth as the oil finish. Just freshly honed two razors from bevel set. Both progressions started the same - Suehiro 1,500 to Shapton Pro 2,000 to Suehiro Rika 5,000 to Shapton Pro 8,000. Then they diverged and one went to my new natural stone and got 100 laps on a smeared few drops of oil. The other got Shapton Pro 12,000 and Suehiro Gokumyo 20k. Both razors then got 10 laps on nylon web hanging strop and 100 laps on SRD English Bridle plain leather hanging strop. Both are killing the HHT. Couple more days and the competition is on.

25Likes

25Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote