Results 201 to 210 of 215

Thread: Apache Black Gila

-

10-29-2015, 03:05 AM #201

Lol, it wasn't that bad, and after seeing how beautiful Keith's stone was, I knew I was going to do at least one side anyhow. I figured on two hours for one side though...and was pleasantly surprised when it came in as quickly as it did.

Can't wait to do an actual razor on it and shave with it. Might even do it tonight.

-

10-29-2015, 03:52 AM #202

-

10-29-2015, 04:08 AM #203Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,496

Thanked: 169

Diamond saw of some sort with some cooling solution to prevent thermal shock? IDK

-

10-29-2015, 04:12 AM #204

-

10-29-2015, 04:26 AM #205Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,496

Thanked: 169

I would not mind trying the water soluble honing solution on my la lune/special stone/vermont slates/vosgienne

-

10-29-2015, 08:11 AM #206

It can be cut with a regular cutoff wheel on a 4.5" angle grinder. If you used a diamond cutoff wheel it'd be even easier. I cut mammoth tooth the same way. If you remember, I knocked down the highest spots on mine with a plain old angle grinder wheel. I could easily have cut it all the way through by putting the blade on edge.

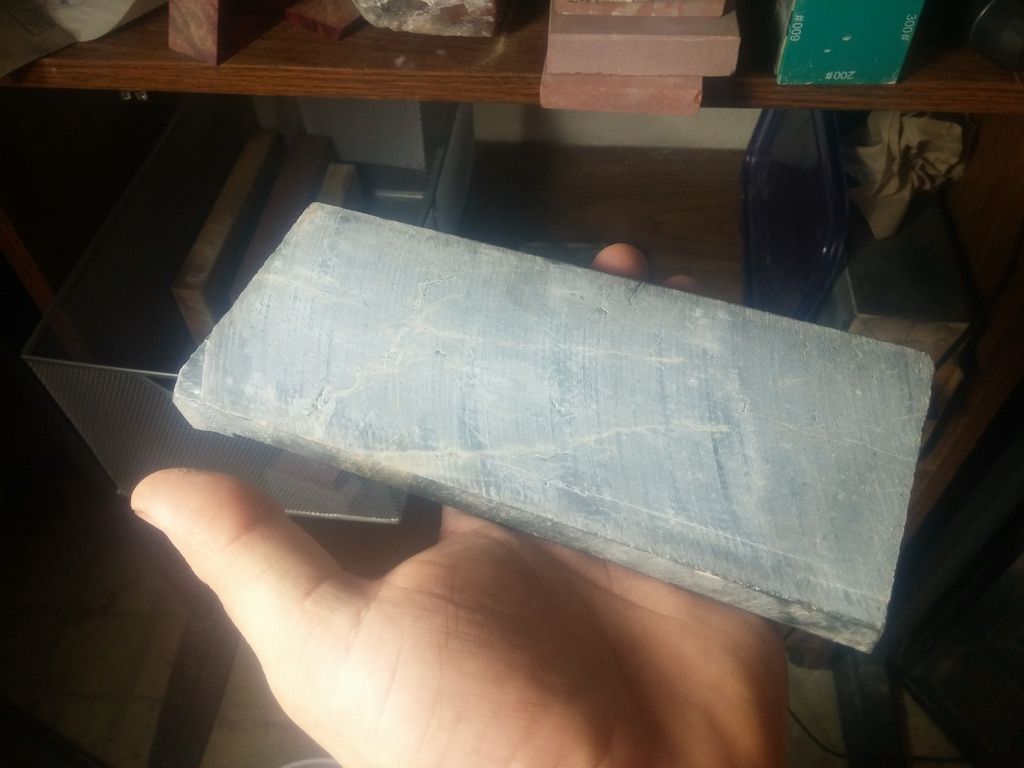

Also, just for comparison and reference sake, here's where I started with this stone altogether:

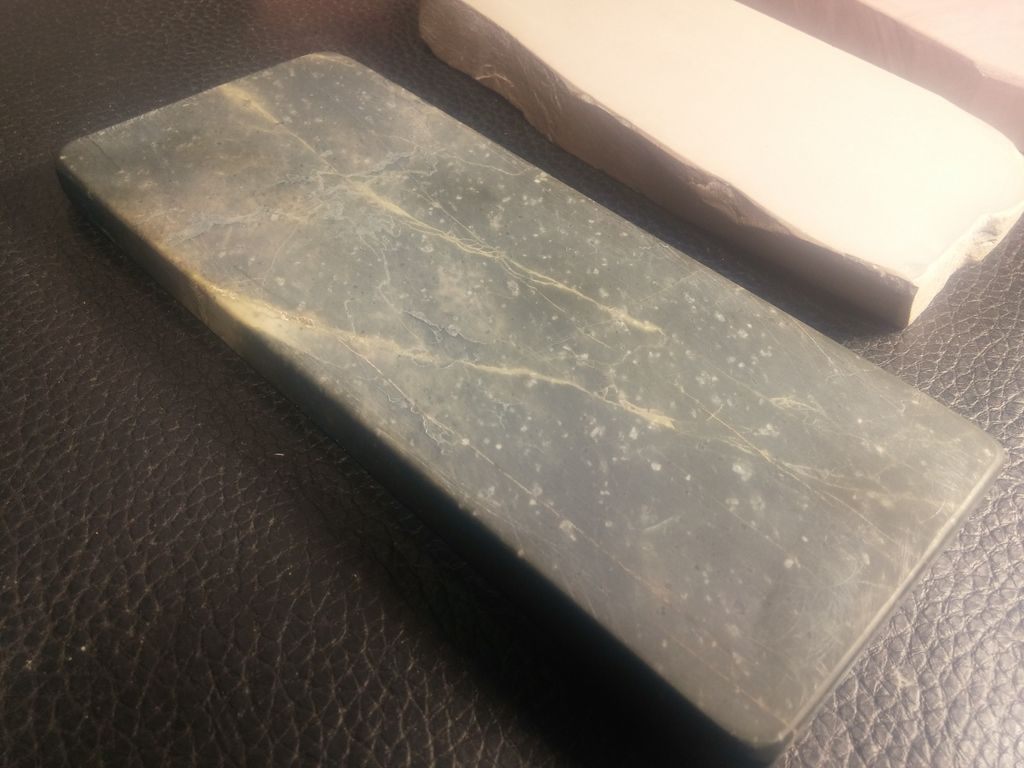

And this is what I have now:

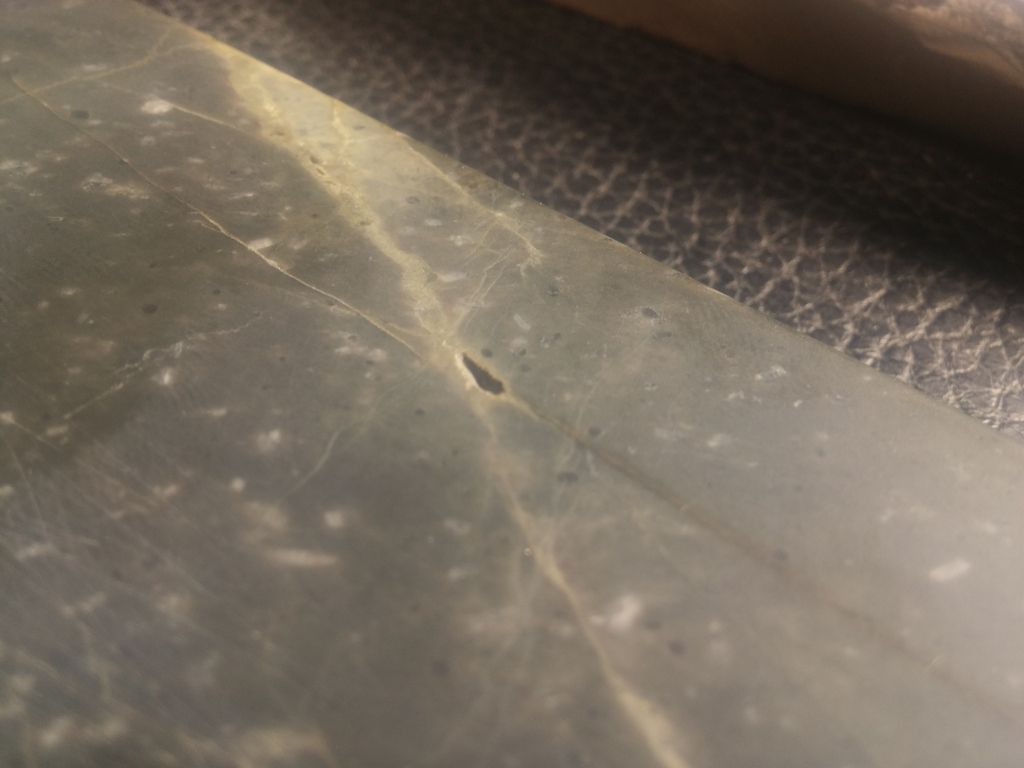

This is the side I've been using.

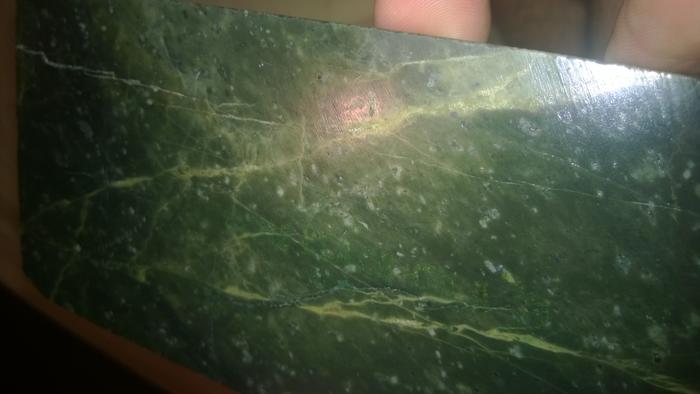

This was the back side, that I took from scratch tonight.

You can see the two pits clearly, one per side. This stone is a freaking dream to work with now though, lol.

Also, I talked to Derrick on the phone tonight, and got the back story from him in regards to his stone. Before I continue though, I want to say in his defense that 90% or more of this he talked about in the video...but without the context, it didn't really come across as he intended. First, it wasn't sent from Terry to him. He got it from a friend who from my understanding got it from Nelson. Second...the stone was known to have issues from the beginning. It has been through multiple people and all of them had issues with toxic patches in it. Derrick told me it was offered to him to try out with that clear understanding...and he even said at the end 'This one does appear to be toxic, that is what my friend said about it'. All of us that jumped in with both feet on him did so without understanding what he meant lol. He KNEW the stone would probably have problems. He was more video reviewing that specific stone, than doing a review on Apache Gilas in general. It just got lost in the context of the video I guess. What's going on is pretty clear to me now. If you look at the pictures I posted, you can see that my pits are in the yellow areas. There was quartz-like sand embedded in both of them that I had to scratch out. In the final close up picture above, you can see how the sediment continues through in a more shallow vein right to the edge (on the left). You can also see that I need to dig more of it out in both areas to have a truly stable stone. THAT is what's throwing out grit on Derrick's stone. The yellow veins on his have those spots in three areas. We talked about digging them out and seeing if the stone is salvageable. I believe the thing is 8.5" x 3.5". That's a HUGE Gila, lol. It would truly suck if it wasn't able to be saved.

We also talked about resurfacing the back side like I did on mine tonight and trying again. He said the back side does look better and he was planning on it anyhow.

Another thing that should be mentioned, is that Derrick is a huge supporter of Terry in general. He's had a few Strata and Reds, and has been involved with Terry's stones in general for pushing 1.5-2 years now I guess. He made the point tonight without prompting that he knows full well Terry would take the stone back and replace it with one that worked. I'm not sure how the price point he was making played into that, but all in all, I think the entire video was taken out of context by a lot of us, and that he didn't even consider that it might be when he made it, lol.

Anyhow, I'm off to do a bit of honing, then shaving. I'll see if I can rig my tripod up to catch some of it on video.Last edited by CrisAnderson27; 10-29-2015 at 08:13 AM.

-

The Following User Says Thank You to CrisAnderson27 For This Useful Post:

Hirlau (10-29-2015)

-

10-29-2015, 08:21 AM #207Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,496

Thanked: 169

Interesting stuff that your problem zone ran deep. Mine opened and shut during lapping like an eye blinking and it came from the slab preceding yours. I'm guessing he will find a usable track somewhere in that stone. Conditions change thick and fast I found. Here's some fun, the bottom of my hone where your pit would meet the inclusion on the back.

Interesting stuff that your problem zone ran deep. Mine opened and shut during lapping like an eye blinking and it came from the slab preceding yours. I'm guessing he will find a usable track somewhere in that stone. Conditions change thick and fast I found. Here's some fun, the bottom of my hone where your pit would meet the inclusion on the back.

Last edited by kcb5150; 10-29-2015 at 08:23 AM.

-

10-29-2015, 07:57 PM #208Senior Member

- Join Date

- Aug 2013

- Location

- NYC, NY

- Posts

- 1,496

Thanked: 169

The thing I took issue with on mine was the inclusion to bulk material transition zone. It really annoyed me to be able to feel it even though it was doing no harm seemingly so I went out of my way to delete it to a spot where there was a homogenous feel. Can you feel this on yours?

-

10-29-2015, 09:00 PM #209Senior Member

- Join Date

- May 2013

- Posts

- 143

Thanked: 32

I don't like speaking for someone else, but my guess is that Keith cut that with a hacksaw and a silicon carbide blade. It's slow and tedious, but gets the job done and you don't have to worry about a fissure or line letting go from vibrations or heat.

And yes, he's a cool guy. He and Nelson have helped me immensely with their no BS approach to things.

-

10-29-2015, 09:41 PM #210

I love that attitude. I hate pretentious honing professors that make honing seem like alchemy. It isnt.

Don't drink and shave!

49Likes

49Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote