Results 11 to 20 of 66

Thread: Escher loved natural combos!

-

06-10-2013, 10:50 AM #11

Since we have here many people with great knowledge of Thuringians, how big variation do you see in their hardness regarding their color? We always talk about how fine they are, but never about how hard they can be.

My opinion for the above is, I don't see big difference on the edge from a dark or a light colored one. And for me, there is not a chance to distinguish the edges between a good yellow and a good black.

-

06-10-2013, 11:36 AM #12Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

Great thread, Hatzicho1

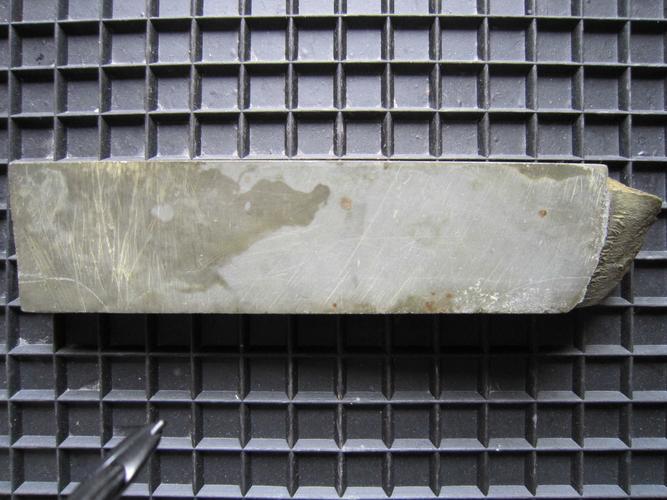

Here's another one with a diagonal split:

It's a thuringian that I had a few years ago. There was some difference between the two sides - one had only a very thin strip of the lighter layer, but it wasn't that marked.

Regards,

Neil

-

The Following User Says Thank You to Neil Miller For This Useful Post:

Utopian (02-06-2018)

-

06-10-2013, 11:54 AM #13

Very cool thread. Thanks a bunch for sharing.

-

06-10-2013, 06:16 PM #14

I don't know if I have 'great knowledge' but I have a bit of experience honing on various Eschers, Hohenzollerns, and Muellers. I have seen three yellow/green Eschers that not only had the y/g end label but another label on the opposite end that was printed "guaranteed soft."

My impression ..... not definite, but an impression gotten from honing and lapping, is that the y/g, and light green are softer than the blue green, and therefore faster, and that the dark blue is the hardest of all, and the slowest of all. FWIW, I had a dark blue 'Celebrated German Water Razor Hone' with the E & Co cup label, that was as fine a finisher as any I've used, albeit slow to achieve the results. My 2 cents.

-

The Following User Says Thank You to JimmyHAD For This Useful Post:

Vasilis (06-10-2013)

-

06-11-2013, 04:16 PM #15

Vasilis,

indeed the lighter stones are in most cases softer than the darker stones. Softer means, that the binding in the stone matrix is less strong in the yellow/green stones than it is in the blue stones.

You can feel this only a little when honing on the wet stones without slurry, but more when you lap the stones or raising up a slurry.

I normally never raise slurry on the yellow green stones - only on the green or blue stones and only use the yellow-green ones for endfinishing. While raising slurry you loosen abrasive material, in this case quartz, out of the stone matrix, the honing will be faster but also coarser. This is a lot stronger on the yellow stones than on the blue stones according to my experience.

An interesting issue in this context is, that the yellow/green stones in nature are strongly exposed to alteration, the blue ones much less. This is also one reason why the blue stones will be found near to surface the yellow ones are harder to find only deeper in the earth, therefore were harder to mine in the past and higher in costs.

I once get a small perfect green colored thuringian stone from an old grinder.

The stone looked dirty when I got it and I began to clean it under water as soon as I got back home. Under the water I realized, that it was not earth or dirt that I washed from the stone surface but the stone itself that was in dissolving process.

The product of this alteration or dissolving process is geological called “Mehlstein” (don’t know if flour stone is correct translation).

I am not sure about the reason for this. You can observe that in the yellow stones there is sometimes a lot of visible organic material like fern, small leaves, etc. and I suppose a lot more of smaller not visible organic material.

I am no expert in mineralogy but my thoughts for one reason of the stronger alteration of the lighter stones is a higher amount of organic material. In the earth between other layers of slate, quartz and chalk the stones are stable. If they get in contact with the oxygen of the air the organic material slowly oxidizes to CO2 and therefore leads the decomposition of the stone material and might also be the reason for a less stable stone matrix…?

-

The Following 5 Users Say Thank You to hatzicho For This Useful Post:

JimmyHAD (06-11-2013), Margeja (06-11-2013), Neil Miller (06-11-2013), RusenBG (03-22-2018), Vasilis (06-11-2013)

-

06-11-2013, 04:53 PM #16

Something else I have observed is, the light colored stones feel like something between a mudstone and a slate. Like, slate in a matrix of mudstone. Something kind of like the Japanese Aoto, if you have ever tried it. Or the opposite, I don't know.

The darker ones, feel more like a lightly porous slate. And, in those, the feeling, the light coloured above give, is less pronounced.

Maybe that's another reason light colored ones are more in demand. They might be as fine as the dark ones, but feel friendlier while honing. The softer the stone (but not too soft), the more pleasant the experience.

I'm not sure if my observations are correct, and if I am wrong, please say so. It will help me, and, anyone who is looking for information about Thuringians.

-

06-11-2013, 05:03 PM #17

You are absolutely correct Vasilis,

the correct expression of the upper-devonian thuringian whetstones is mud-slate (german: Tonschiefer). They belong to the slatestones but having a a high correlation to mudstone!

-

-

06-12-2013, 07:54 AM #18

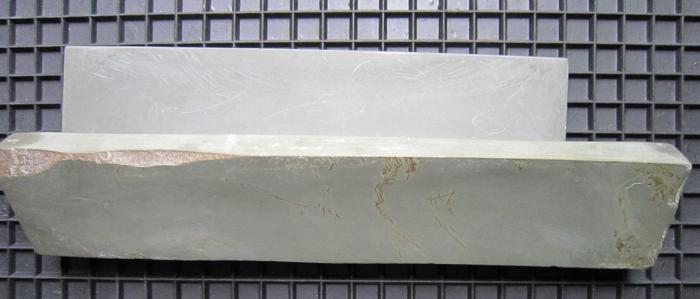

Here is a sample of my two colors Thuri.

-

The Following User Says Thank You to Bushdoctor For This Useful Post:

25609289 (06-12-2013)

-

06-12-2013, 10:12 AM #19

Thanks for sharing Bushdoctor,

this one is from the Deutsche Schleifmaterialien Gesellschaft (DSG) in Steinach/Thüringen. The company distributed thuringian hones and other grinding materials in the early 20th century.

-

-

02-06-2018, 02:11 PM #20Senior Member

- Join Date

- Feb 2014

- Location

- Oklahoma City

- Posts

- 220

Thanked: 71

293Likes

293Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote