Results 1 to 10 of 22

Hybrid View

-

01-13-2014, 05:08 PM #1Senior Member

- Join Date

- Nov 2012

- Location

- Across the street from Mickey Mouse in Calif.

- Posts

- 5,320

Thanked: 1185

Most of the article is about...

" micro chipping as a result of over honing."

Micro chipping is due to the grit levels affect on the steel. Not over honing.

"the edge of the edge becomes thinner as it becomes more refined"

I think he shoots himself in the foot with this comment as it completely negates his statement..." the thickness of the spine of the razor combined with the width of the blade determines the edge angle.

How can the edge get thinner if the angle never changes?

While I don't find the man completely wrong I think he went off road with the micro chipping issue. You may hone longer trying to get these chips out not realizing that the grit level your at is creating them which is really just a waste of steel. I think 1 of the more important variables not mentioned is the pressure applied to the blade. I would think a wire edge would show up if to much pressure is on the blade forcing the angle to change. This would definitely cause a wire edge by forcing the very edge of the blade off the hone because the top of the bevel has more or less become a fulcrum which will be ground down as you continue honing.Increasing the height of the bevel and extending the edge to a point where it is bent away from it's original point in the overall geometry of the razor as it was.

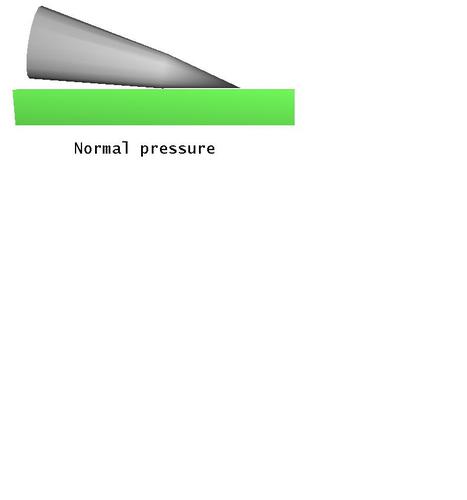

My 3d drawing of a normal hone angle

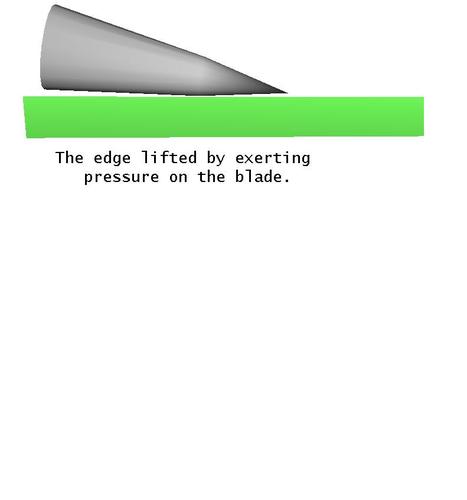

Add some pressure and the edge will lift. The top of the bevel will now be honed away thinning the edge.

The geometry has now changed.

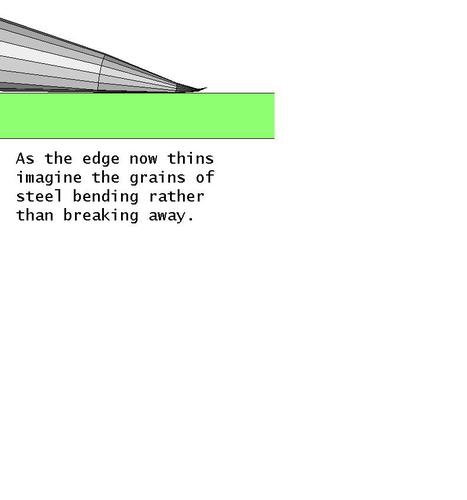

As the blade thins 2 things will happen. At the lower grits not only will you have the grains of steel breaking away but also bending away from the surface of the hone. As you move up in grit the impact of grit will decrease and more likely cause the grains to bend away from the hone rather than break them away. The longer you hone (over hone) the longer and more curled the edge will get. Therefore creating the wire edge the author of the article claims can not happen.

In support of my theory I give you the example of rolling an edge with a strop. Here you are bending the grains at the edge because of the angle/pressure of the leather against the edge. Because the blade is traveling in the opposite direction of honing it is less likely to break the grains that make up the very edge and merely bends them.Last edited by 10Pups; 01-13-2014 at 05:12 PM.

Good judgment comes from experience, and experience....well that comes from poor judgment.

-

The Following User Says Thank You to 10Pups For This Useful Post:

ColonelG (01-13-2014)

-

01-13-2014, 05:19 PM #2

18Likes

18Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote