Results 21 to 30 of 59

-

01-10-2015, 01:47 PM #21Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

If not pressure how would you account for the OP’s issue, same razor half the grit size and same stria pattern?

-

01-10-2015, 02:01 PM #22

Thanks. I though I was watching my pressure, keeping the same pressure on the 16k as with the 8k. I'll keep a closer eye on it. But as with honing to the edge, I wasn't worried about getting to the edge as much as seeing what the 16k was doing. But I do agree with the chalk illustration and will try lighter pressure next time.

Plus this is a knife edge not a razor. But I was concerned about how my razor edges are doing on the same stone if I was noticing this on the knife.Last edited by rlmnshvstr8; 01-10-2015 at 02:05 PM.

A fool flaunts what wisdom he thinks he has, while a wise man will show that he is wise silently.

-

01-10-2015, 02:37 PM #23Junior Member

- Join Date

- Jun 2014

- Location

- Mexico

- Posts

- 16

Thanked: 2

I had a similar issue with the SG 16K and an Atoma 400. Got so frustrated with it that I called Shapton USA and they sent me a Shapton DG flattening plate to try out to see if it worked any better. Great plate, but similar issues. After several phone calls with Harrelson Stanley of Shapton USA who is an extremely knowledgeable and helpful fellow I found out:

The binder on the 16K and 30K is different from the other SG stones. That binder could be causing some of your issues. It can be made to work just fine though. Less pressure, clean water, no slurry, and less laps. I went so far as to "flatten" my 16k with my 8K to take out some of what looked like scratches, but to be honest i'm not sure that did anything. Try getting as good a finish on the 8k as you can, and then try the less is more approach.

Good luck and look forward to your results.

-

The Following User Says Thank You to mjwit For This Useful Post:

rlmnshvstr8 (01-10-2015)

-

01-11-2015, 12:02 AM #24Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Well, I thought he said it was a knife first of all, but without being there and seeing exactly what he is doing I can't really do much accounting for it. My first thought would be perhaps those are 8k scratches and maybe he just wasn't hitting where he thought he was with the 16k. OP was this freehand sharpening?

-

01-11-2015, 01:04 AM #25

Yes this was freehand sharpening. But I just took the pics based on an experiment I was doing because I was noticing in spots where I had just finished on the 8k became scratchier after hitting it on the 16k. But I haven't had a chance to get out my 16k again yet, but I do think mjwit maybe on to something about the binder that I'm hoping to learn more about. Have to learn how to use my toys properly.

A fool flaunts what wisdom he thinks he has, while a wise man will show that he is wise silently.

-

01-11-2015, 06:00 PM #26Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

I had a similar issue with the SG 16K and an Atoma 400. Got so frustrated with it that I called Shapton USA and they sent me a Shapton DG flattening plate to try out to see if it worked any better. Great plate, but similar issues.

And… what happened?

You are talking about lapping a stone… it makes no difference. We lap a stone face to get the stone face flat. 400 grit is plenty small enough to produce a flat surface.

What counts is, how the stone performs on steel not what the stone face looks like. Finishing a stone face on an 8k would make no difference.

It is about the pressure. Many of us finish synthetic stones daily and have done so for years with a 325 grit diamond plate, on synthetic stones up to 30K.

It is not the stone…

Pressure… you are using too much pressure on your razor. At 16k you should be very lite pressure, to weight of the blade for finish honing.

-

01-11-2015, 06:16 PM #27Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

Hmm, I have found that to be not entirely true personally. I have done a lot of experimenting and testing with varying lapped surfaces on my different stones, from very hard naturals to very soft synthetics. Hours upon hours of testing. On very soft stones it makes as near as no difference how they are lapped as they will quickly revert to their natural texture when used - often within a few laps on very soft stones. On medium to harder stones the surface texture can make a significant difference to the way the stone cuts and the finish it imparts. The difference on something like a Shapton (medium hardness) stone when being lapped with a brand new 325 grit diamond plate vs. with a well-worn 325 grit diamond plate is quite significant. In point of fact, if the OP is lapping these two stones with a brand new or not very worn 325 diamond plate I'd say that would explain the issues he is having right there if honing with light pressure. He should lap the stones then rub them together until they are smoothed, (most of the scratches from the 325 are gone) and I think he will see a difference in finish immediately.

-

01-11-2015, 06:24 PM #28Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Guess we’ve all been doing it wrong…. OMG

It’s not the stone…

-

01-11-2015, 07:57 PM #29Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

So first we are talking about Synthetic stones, and second he is lapping with a 400 Atoma and a Shapton Lapping plate, both of which produced the same results…

What cuts the steel, the top of the grit… or the bottom of the land made by the lapping plate grit?

The STEEL razor will ride on top of the grit… unless the user is using too much pressure.

Besides, this is a 16K stone, where he should be using weight of the blade pressure to finish hone anyway.

It is not the stone or the lapping plate… as he proved to himself.

This user and the OP are simply using too much pressure… just like the chalk photos clearly demonstrate.

-

01-11-2015, 10:14 PM #30Senior Member

- Join Date

- Sep 2013

- Location

- NW Indiana

- Posts

- 1,060

Thanked: 246

The low point of the groove doesn't do the cutting, that's correct, and no one is arguing that point. But to say that the surface prep makes NO difference is not correct in my experience unless you are talking about a very soft stone. The difference between diamond plate grits isn't so much the significant factor, it's the freshness of the plates and sharpness of the diamonds that makes more difference. This difference shows up both in finish and cutting speed. The difference is in the amount of stone in contact with the steel, and how those contact points are shaped. The reason light pressure is important I think is that it gives uniform repeatable contact with the stone. Heavy pressure means any change in pressure results in a contact point shift, which makes it more difficult to finish an edge. It can also be important for some razors as heavy pressure on certain razors can result in chipping on a microscopic level.

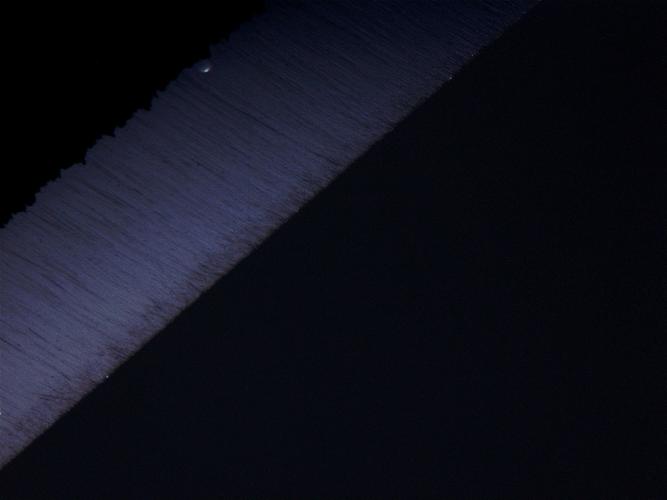

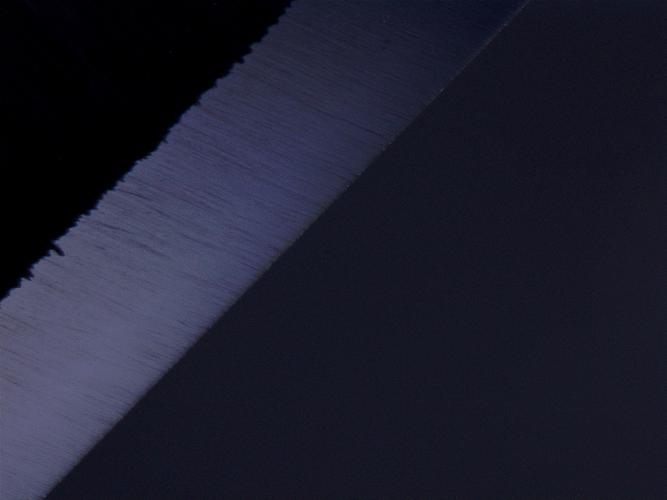

Here are two photos at 200x taken with raking light to emphasize scratch depth. Both the same razor in the same place on the blade. One was honed with weight of the blade, one with about 10 pounds of pressure measured on a postal scale. About the same number of laps for each. Do the scratch depths look significantly different? FYI I just shaved with the heavy pressure edge with no ill results. It shaves pretty much the same as the light pressure edge - maybe not quite as smooth ATG, but indiscernible WTG.

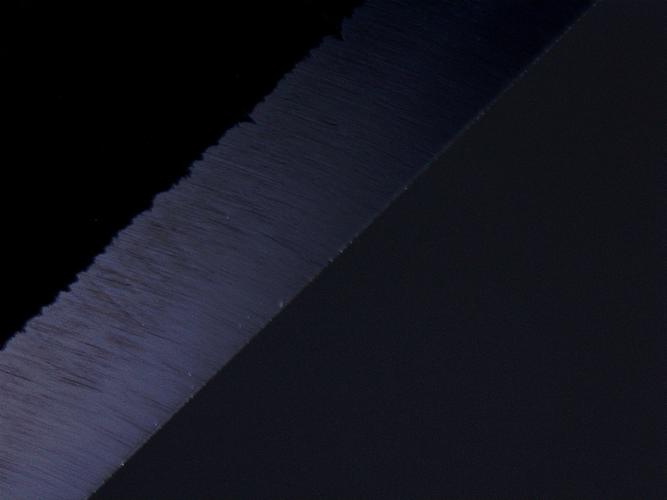

Here are 2 more shots showing the same razor, same edge. One is the result of a stone lapped smooth with a finer synth stone, and one was lapped on 80 grit wet/dry. Look at the drastic difference near the edge. Both honed with weight of the blade level pressure.

P.S. all these shots are honed on the same stone - a Shapton Pro 8k.Last edited by eKretz; 01-11-2015 at 10:51 PM.

33Likes

33Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote